Numerical simulation method for plate impact jet flow heat transfer problem

A numerical simulation and impingement jet technology, which is applied in CAD numerical modeling, complex mathematical operations, electrical digital data processing, etc., can solve the difficult Nusselt number distribution of flat impingement jets and the inability to accurately predict the Nusselt number of impinging plates. Er number distribution and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

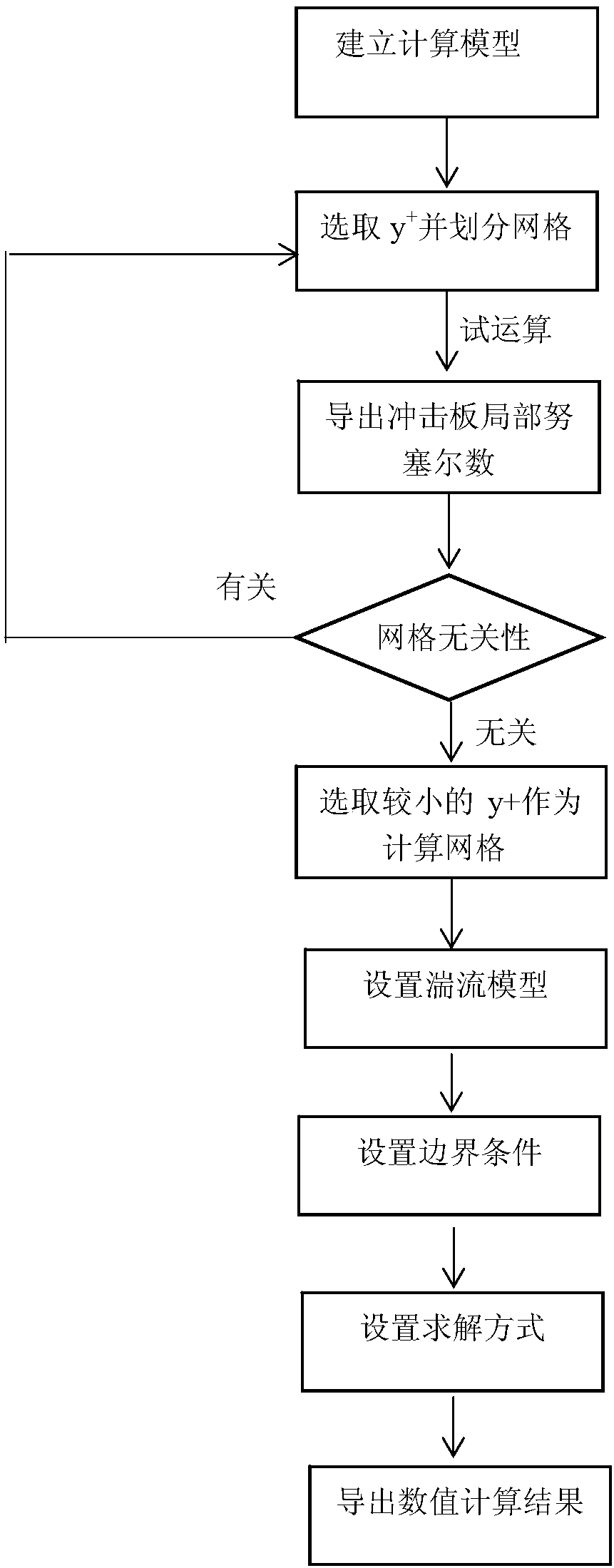

[0049] (1) Establish calculation model

[0050] According to the experimental data, the flat impact jet model including the adiabatic impact surface and the closed plate is established; the experimental model is selected as an example verification, the nozzle width is 0.04m, the impact height is 4 times and 9.2 times the nozzle width, and the length of the impact plate is 50 times the nozzle width.

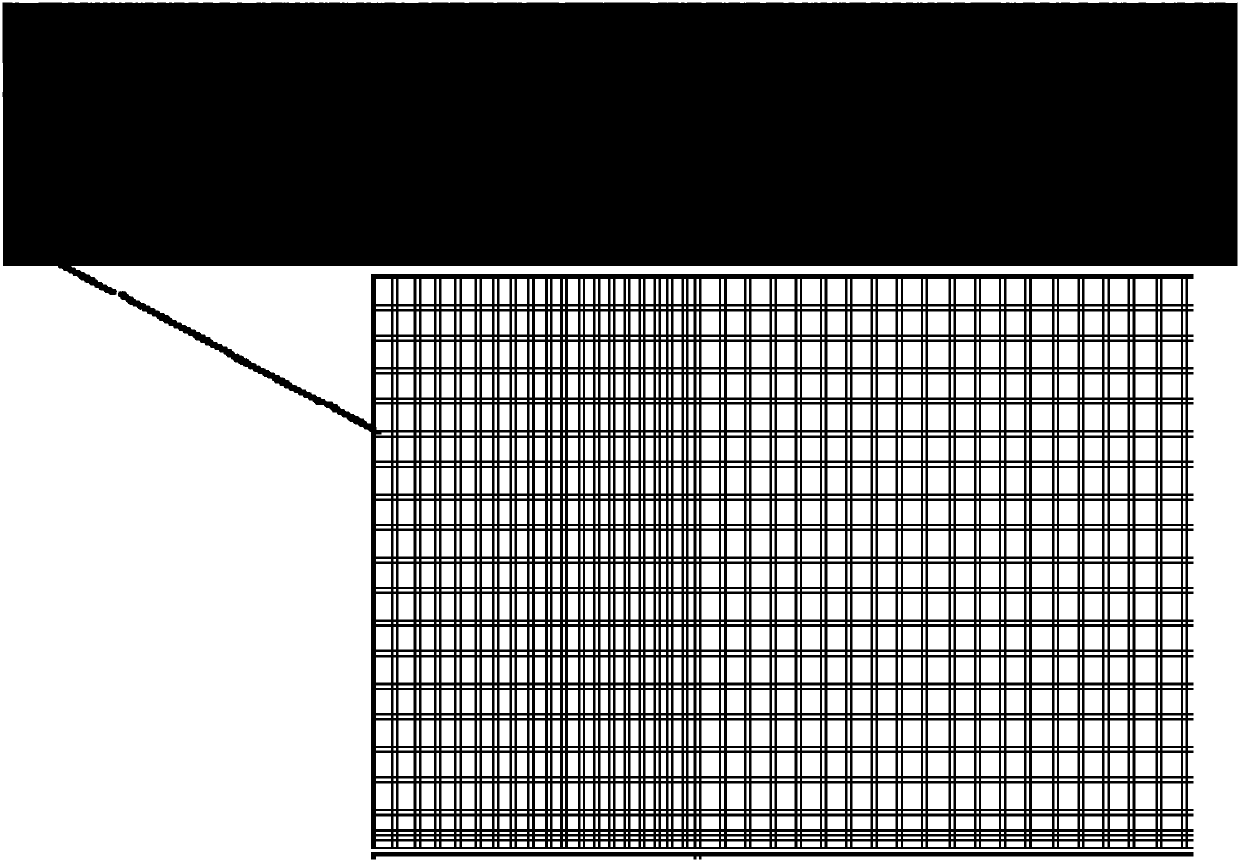

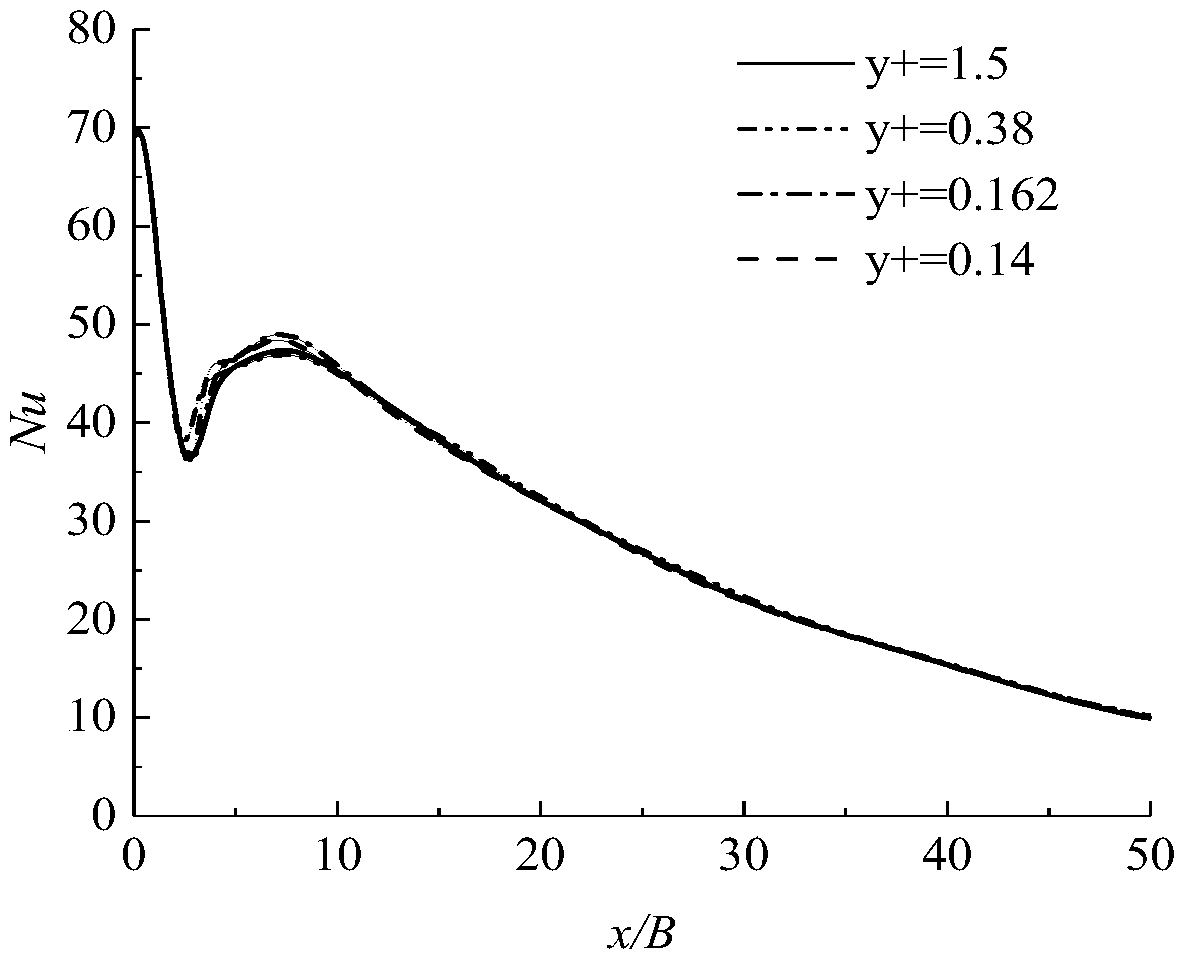

[0051] (2) Grid division of the model and verification of grid independence

[0052]Grid division is carried out in ICEM, and the grid type adopts structured grid, such as figure 2 shown. According to the selected SSTk-ω turbulence model, select a set of y arranged from large to small + Carry out grid independence verification and use ICEM for grid division. Import the divided mesh into ANSYS-FLUENT for trial operation until two adjacent y + The results of the calculated local Nusselt number of the impact plate are similar, so the smaller y is selected + As the optimal grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com