Method for reducing torque ripple of five-phase embedded permanent magnet motor

A torque pulsating, permanent magnet motor technology used in magnetic circuit rotating parts, electric components, synchronous motors with stationary armatures and rotating magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0093] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

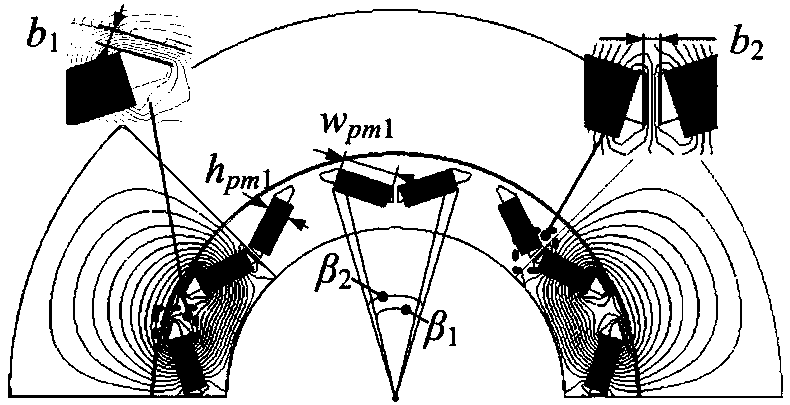

[0094] A design method for low torque ripple of a five-phase embedded permanent magnet motor described in the present invention, the specific implementation objects are as follows figure 1 shown, including the following steps:

[0095] Step 1: Analyze the stator magnetomotive force of the target motor by analytical method, and obtain the stator magnetomotive force expression of the target motor according to the winding function of the target motor and the function of the applied excitation current. The specific calculation method is as follows:

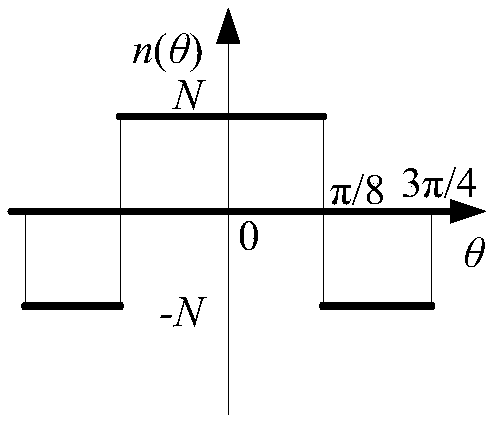

[0096] Such as figure 2 As shown, the Fouri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com