High-boost-capacity type Z-source inverter topological structure

A source inverter and topology technology, applied in the field of high boost capability Z-source inverter topology, can solve the problems of narrow input voltage application range and weak boost capability, so as to increase the applicable range and improve boost. pressure capacity, highlight the effect of substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

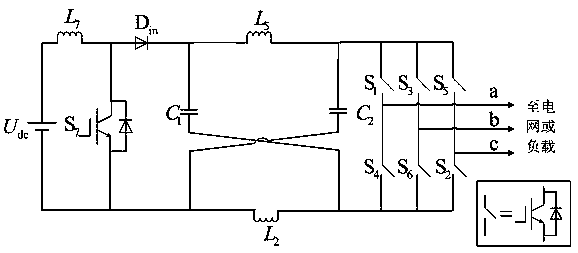

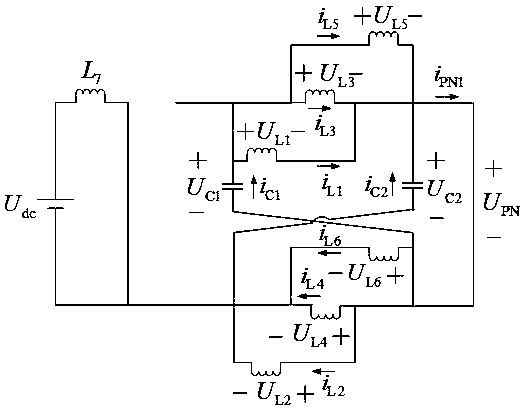

[0024] Such as figure 1 As shown, a high boost capability Z-source inverter topology of the present invention includes a DC power supply U dc , the DC power supply U dc The positive pole and the seventh inductance L 7 The first end is connected, the seventh inductance L 7 The second terminals of the diodes D in The anode of and the seventh switching tube S 7 connected to the first end of the diode D in The cathodes are respectively connected with the first capacitor C 1 positive pole and the fifth inductor L 5 connected to the first terminal, the fifth inductance L 5 The second end of the second capacitor and the second capacitor C 2 positive pole of the first switch tube S 1 The first terminal of the third switch tube S 3 The first terminal and the fifth switch tube S 5 connected to the first end; the first switching tube S 1 The second end of the inverter is respectively connected with the first output port a of the inverter and the fourth switch tube S 4 connec...

specific Embodiment approach 2

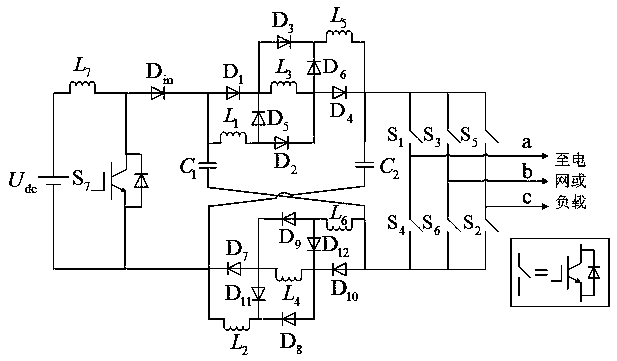

[0026] Such as figure 2 As shown, a high boost capability Z-source inverter topology of the present invention includes a DC power supply U dc , the DC power supply U dc The positive pole and the seventh inductance L 7 The first end is connected, the seventh inductance L 7 The second terminals of the diodes D in The anode of and the seventh switching tube S 7 connected to the first end of the diode D in The cathodes are respectively connected with the first capacitor C 1 positive pole, the first inductance L 1 The first terminal and the first diode D 1 connected to the anode of the first diode D 1 The cathodes are respectively connected with the third diode D 3 The anode of the third inductance L 3 The first terminal and the fifth diode D 5 connected to the cathode of the fifth diode D 5 The anodes of the second diode D are respectively connected to the 2 The anode and the first inductor L 1 The second terminal is connected; the second diode D 2 The cathodes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com