Ceiling for ore transfer

A ceiling and ore technology, applied in the direction of freight vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of inconvenient covering, falling off of quarries, easy to smash people's roads and air, etc., to reduce the air pollution. Pollution, high swing frequency, good primary selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

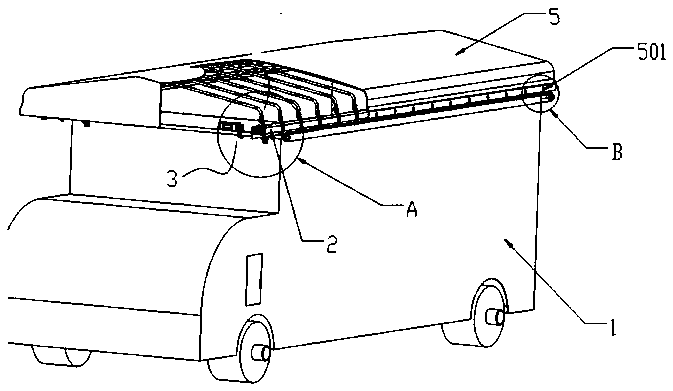

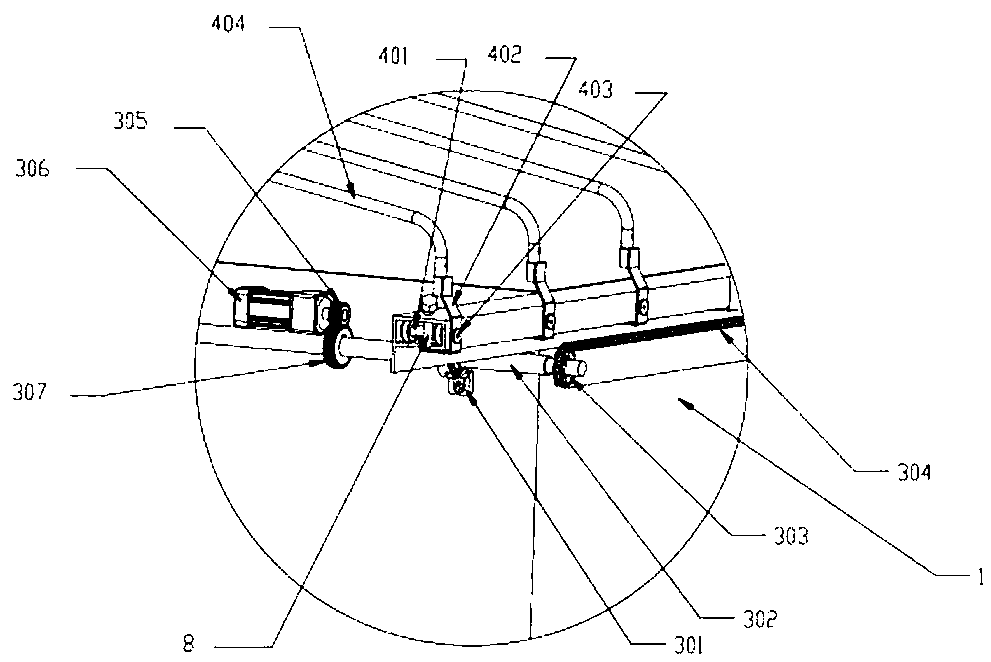

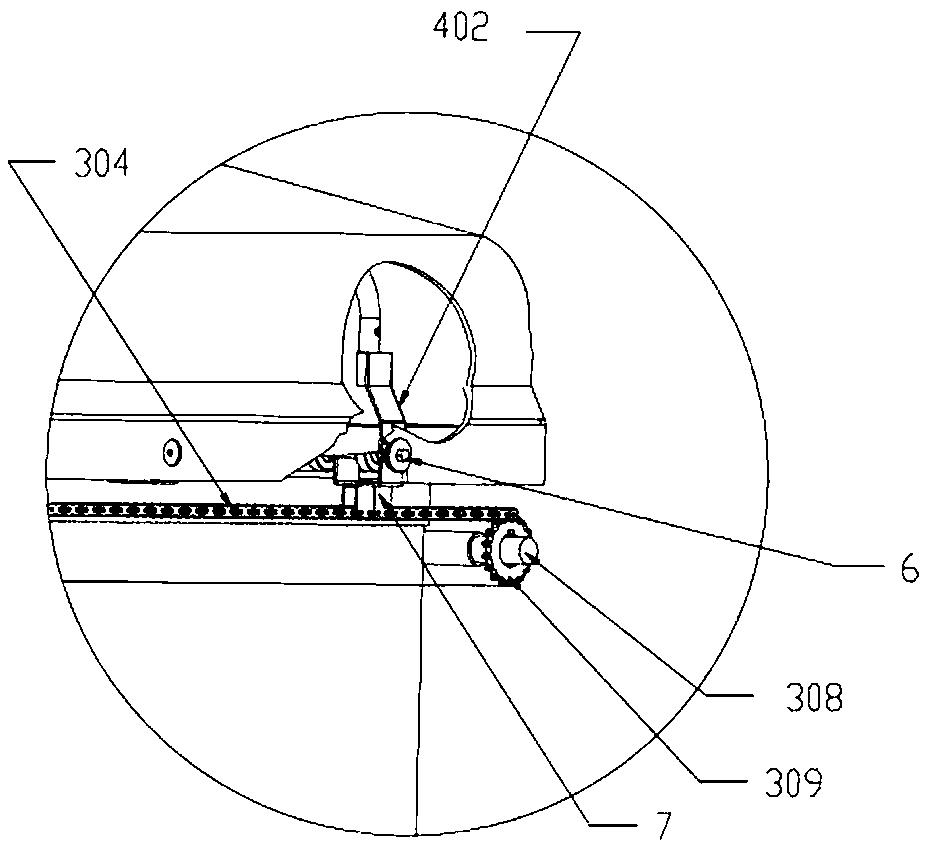

[0018] As shown in Figures 1-4, a roof for ore transfer in this embodiment includes two rails 2 arranged in parallel on the carriage, and on the rails 2, there is a single degree of freedom along the axial direction of the rails 2 There are two slide rod assemblies slidingly connected, there are at least two slide rod assemblies, and a foldable shield 5 for preventing quarry dust from flying is arranged on the slide rod assembly; it also includes a driving device for driving the slide rod assembly , the sliding rod assembly slides on the track 2 driven by the driving device to drive the shielding member 5 to fold or extend. Further, in order to prevent the sliding rod assembly at the front end of the compartment from falling off from the track 2 , a limit bolt 8 can be arranged on the track 2 . The cover can be a rainproof awning, a common material similar to clothing, etc. The single-degree-of-freedom sliding connection is preferably realized by using the L-shaped bracket 402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com