Plastic tying belt

A technology of plastic cable ties and cable ties, which is applied in the direction of flexible and slender components, packaging, transportation and packaging, etc. It can solve the problems of broken teeth in the belt, falling off, and cable ties failure, etc., and achieves simple and effective structure and large tying Strength, effect of increasing effective length of action and binding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

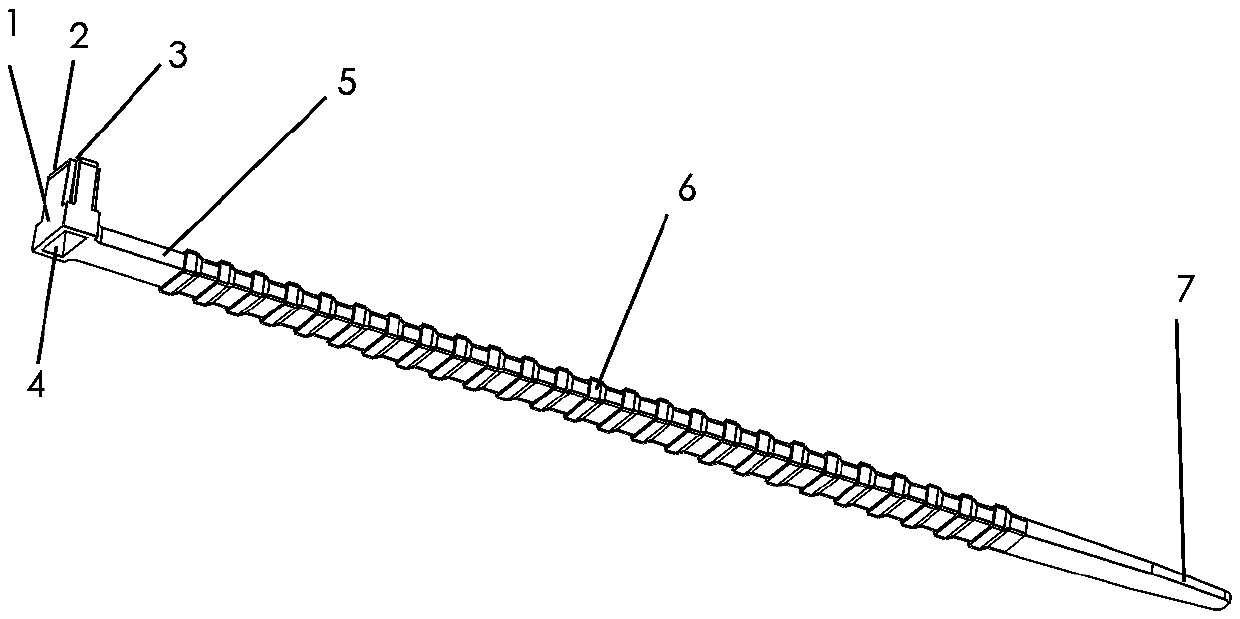

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

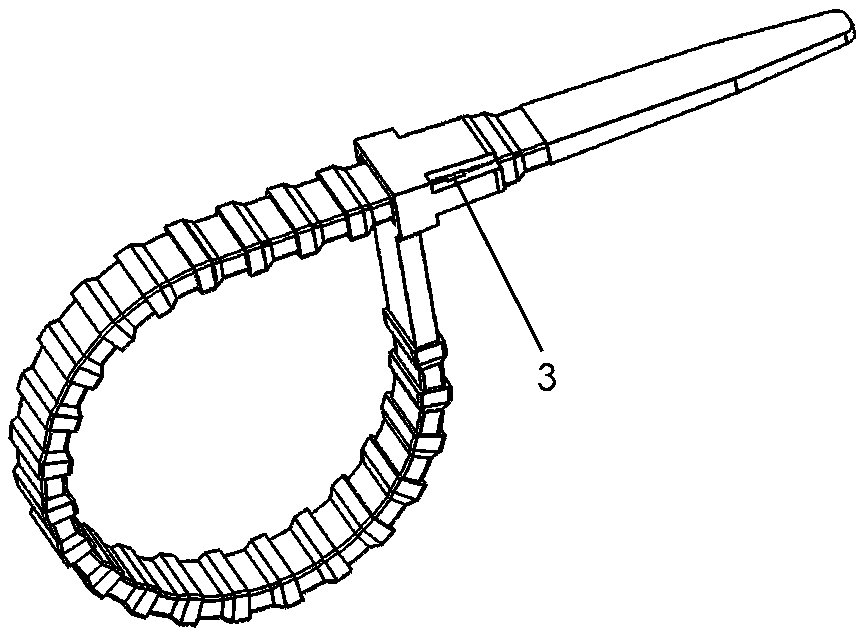

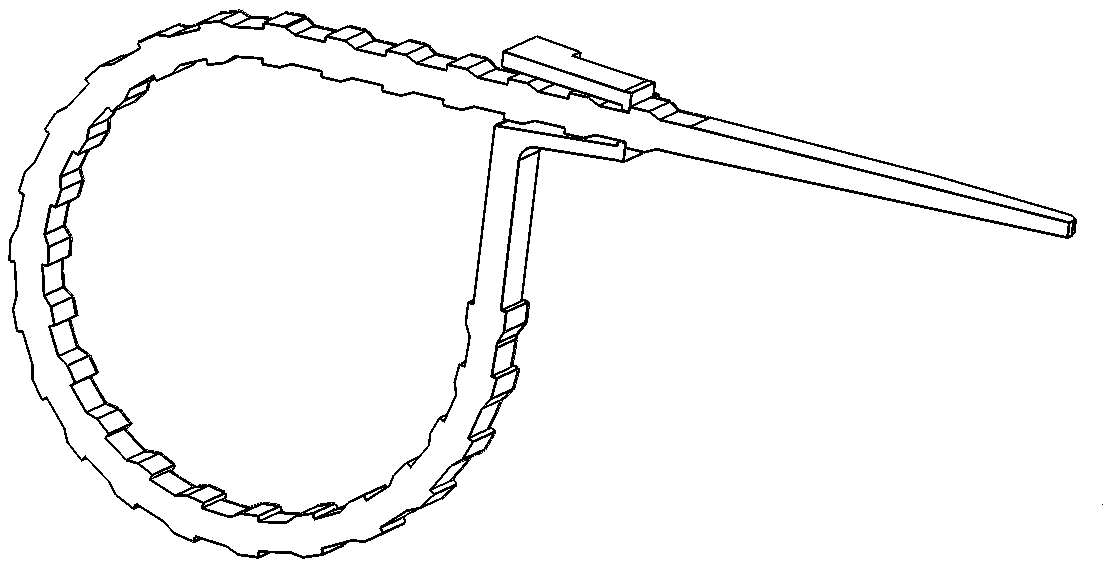

[0014] Such as figure 2 As shown, when the present invention is used, the belt tail is bypassed to be bound and inserted from the belt head socket to form a closed ring, and the belt tail is stretched to tighten the ring, and the small end of the belt body's full-circumference clamping teeth squeezes the outlet corner of the belt head socket The full-circle clamping teeth of the head cut at the bottom pass through the socket in turn, the object is tied tightly, and the tail of the belt is released. The full-circumference clamping teeth of the leading head withstand the large end of the clamping teeth of the belt body, preventing the cassette from being loosened, and the binding is completed.

[0015] Such as figure 2 As shown, the full-circumferential teeth of the cable tie head are located at the outlet end of the cable tie socket, and the corners of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com