AOI (Automated Optical Inspection)-based panel detecting judging method and device

A panel inspection and panel-to-panel technology, which is applied in the directions of measuring devices, optical testing flaws/defects, image data processing, etc., can solve the problems of labor cost, reduced work efficiency, and low luminous intensity, so as to reduce production sites and improve The detection rate and the effect of reducing false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

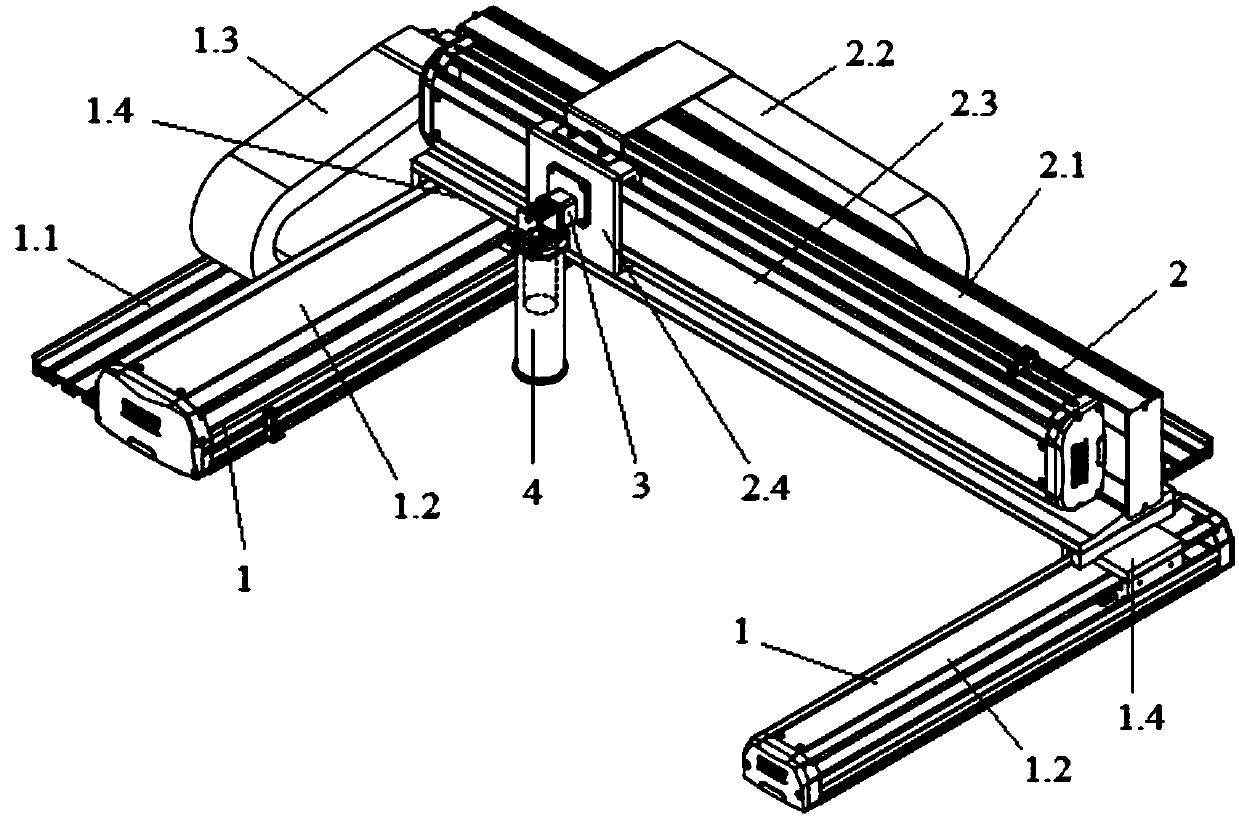

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

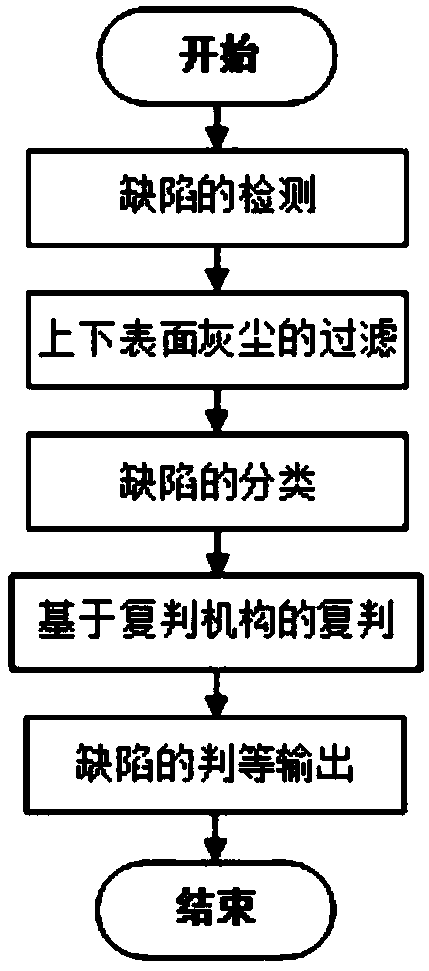

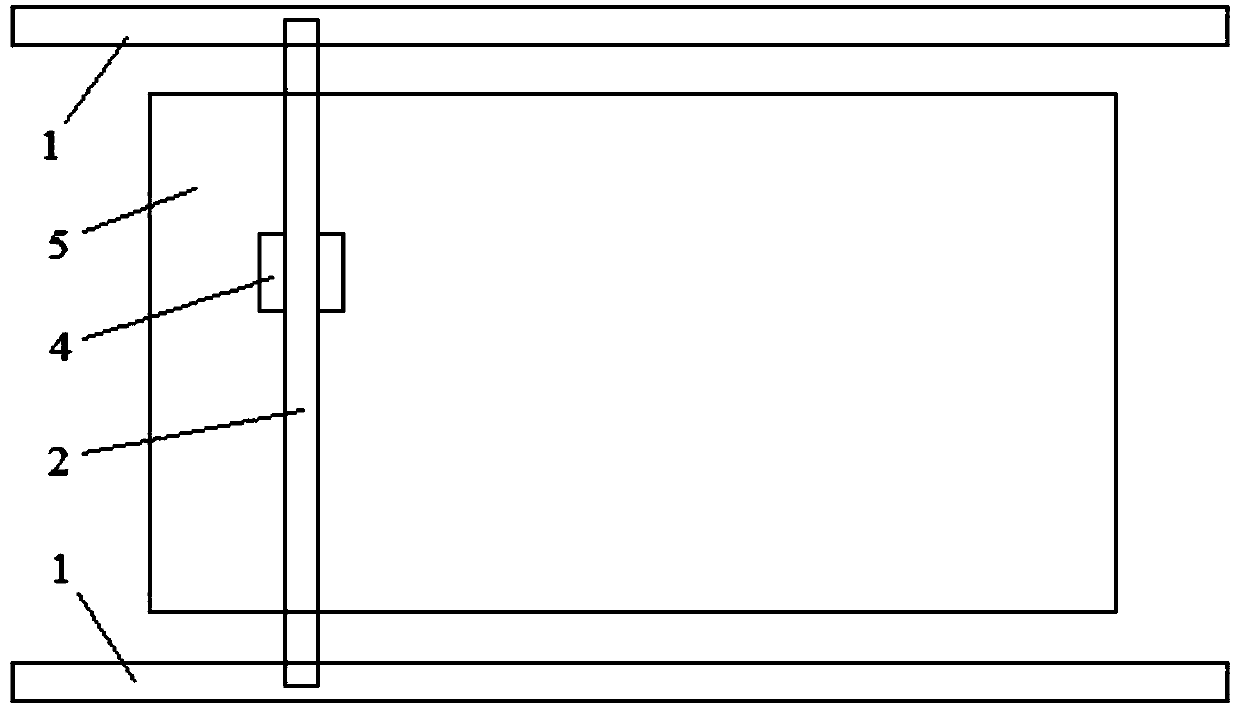

[0036] Such as Figure 1-4 As shown, the AOI-based panel detection method of the present invention includes the following steps:

[0037] Step 1. Perform the initial defect inspection on the panel to be tested through the existing inspection organization to determine different types of main defects;

[0038] There are many types of defects in LCD / OLED panels, and there are some differences in the performance of different types of defects. From the large frame, it can be divided into point defects, line defects and / or mura defects. When performing defect detection, design different patterns for different defects, and then perform image shooting under the corresponding Pattern, and perform defect detection on the captured images, that is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap