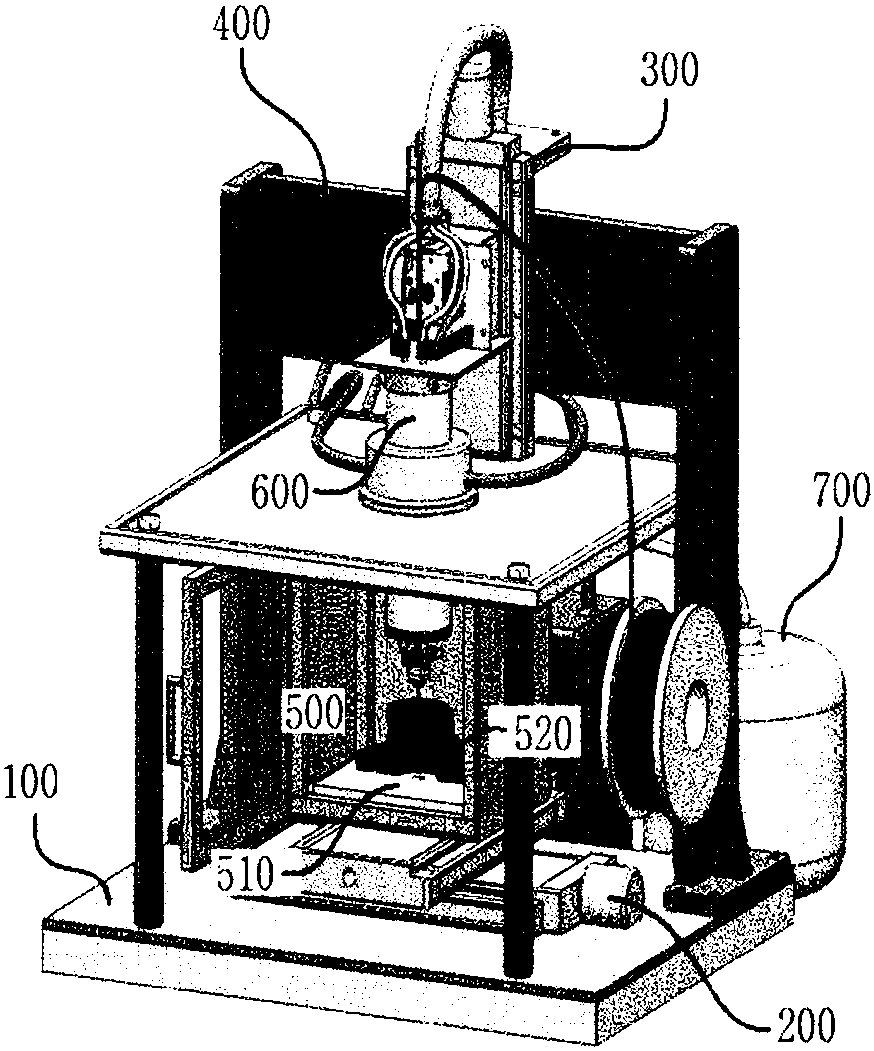

3D printer for metal alloy filament

A 3D printer, metal alloy technology, applied in metal processing equipment, manufacturing tools, additive manufacturing, etc., can solve the problems of shrinkage deformation, weak adhesion to each other, temperature difference of metal wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

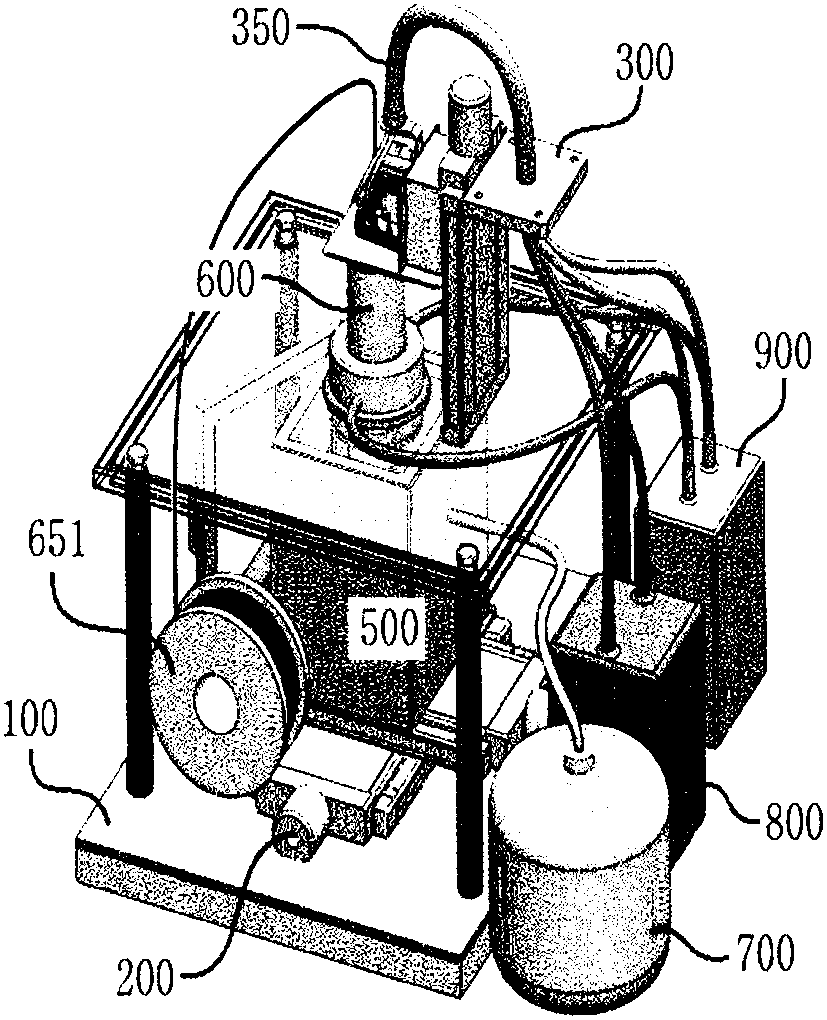

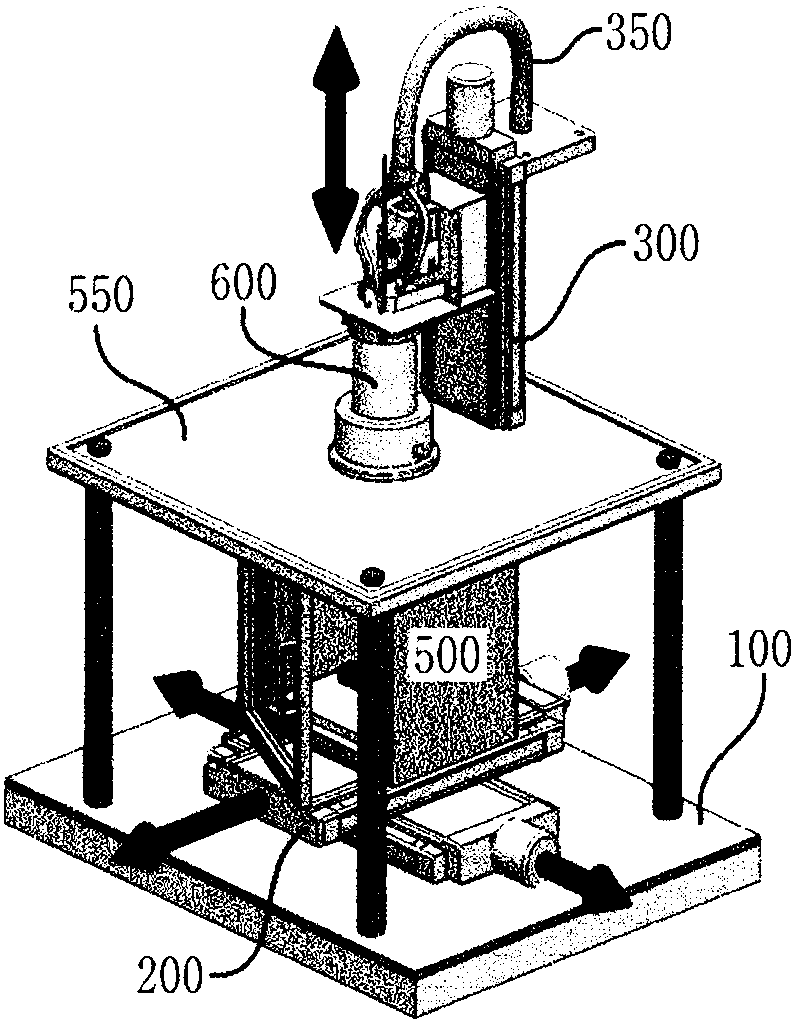

[0042] Figure 4 It shows the overall structure of the nozzle body 600. The metal alloy wire 650 originating from the circular reel 651 utilizes the transfer gear 652 connected to the transfer motor located at the upper end of the nozzle body, and passes through the inside of the tubular nozzle body. The nozzle 610 located at the lower end of the nozzle body 600 is moved.

[0043] The high-frequency current generated by the high-frequency generator 660 provided at the upper end of the nozzle body is supplied to the induction heating coil 620 provided at the lower end of the nozzle body through the fixed electrode 680 .

[0044] Cooling is formed inside the lower part of the nozzle body by connecting the inner pipe 640 forming the cooling water hose 670 along the plumb direction and the cooling water hose 670 originating from the connection line 350 arranged at the upper end of the nozzle body. The induction heating coil 620 and the cooling cylinder 630 of the water channel su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com