Offshore structure, supporting member, skid shoe, and method for moving cantilever

A technology for offshore structures and supporting components, which is applied in the direction of supporting devices, underwater structures, infrastructure engineering, etc., can solve the problems of the limitation of lateral movement of the drilling rig and the inability to reach the required width of the drilling envelope, and achieve a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

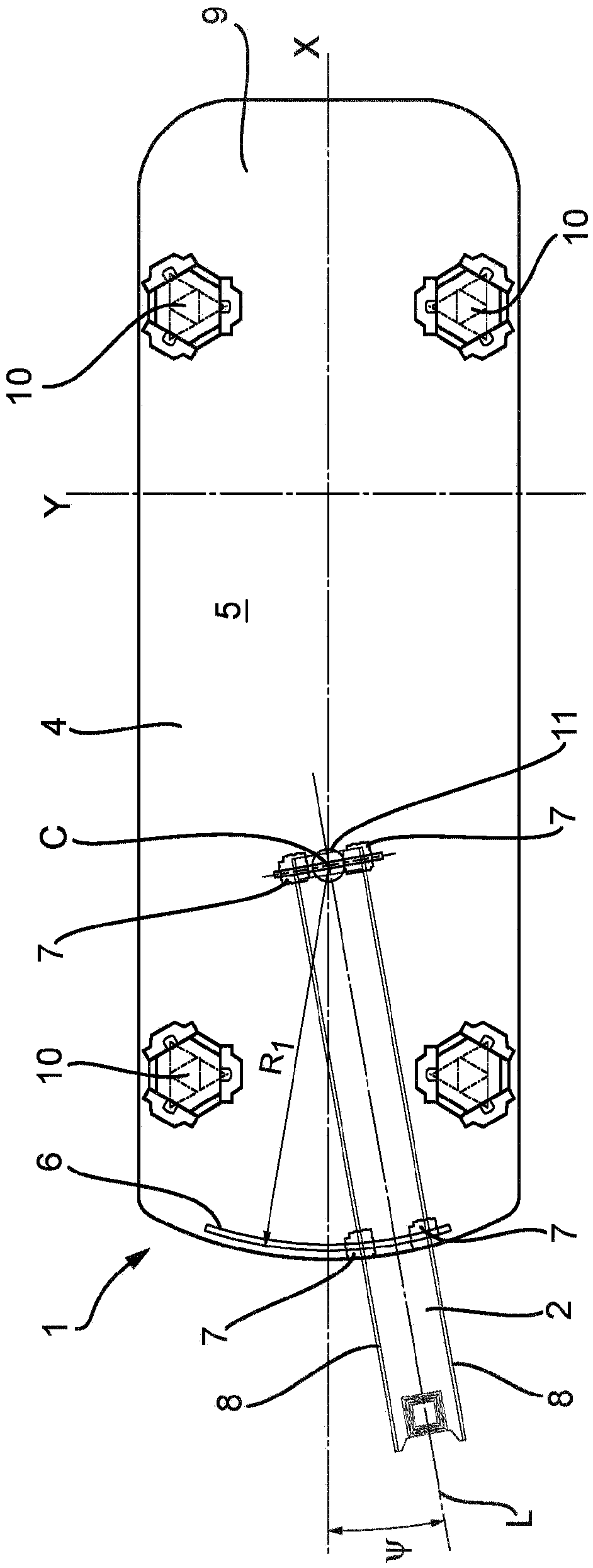

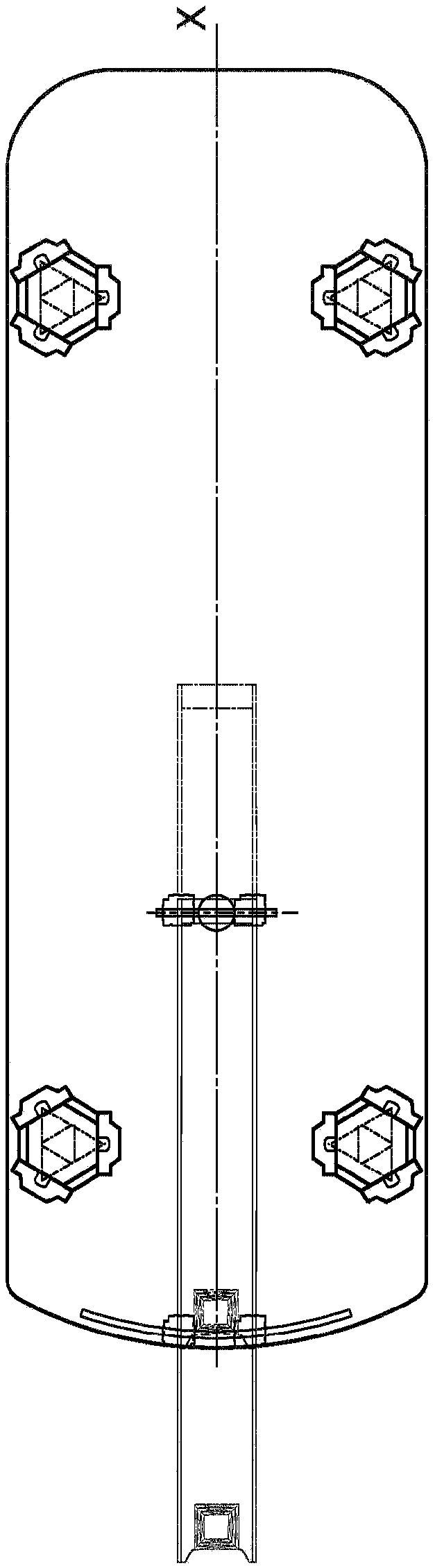

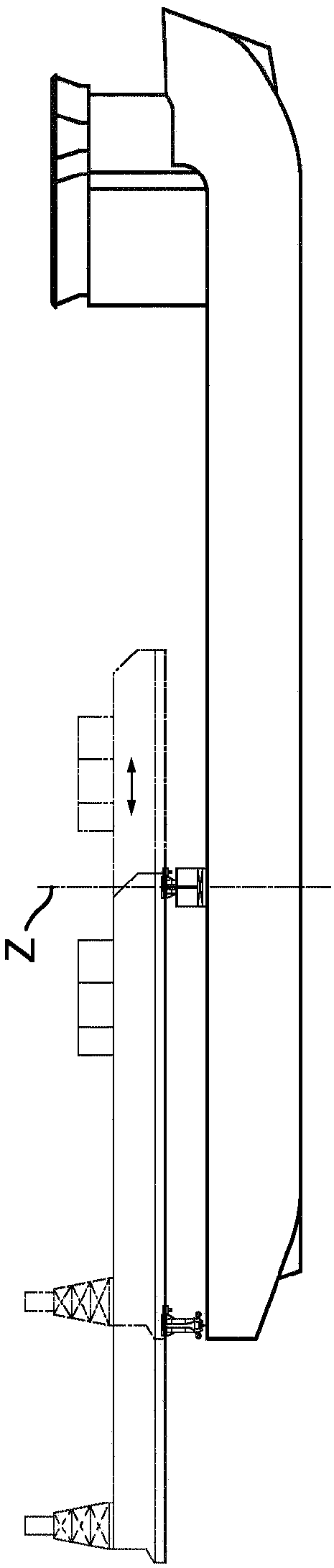

[0091] Typically, the skid system 1 comprises one or more guides, also referred to as deck rails 6, located on the deck 5 for guiding the movement of the support member 7 relative to the deck 5, wherein the skid system 1 is used for 4 (such as a boat or a jack-up) to move the boom 2. The deck rails 6 can be positioned on either side of, in front of or behind the point of rotation C of the boom 2 . The boom 2 itself is provided at its bottom side with a longitudinally extending guide or boom rail 8 . In the embodiment shown here, the offshore structure 9 comprises a platform 4 , a cantilever 2 and three or four legs 10 , wherein the legs 10 are adjustable relative to the platform 4 in a known manner.

[0092] The center line of the platform 4 ship is the X direction. The Y direction is perpendicular to the X direction in the horizontal plane. The axis of rotation extends in a vertical Z direction, wherein the Z direction is perpendicular to the deck plane of the X and Y dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com