Adjustment device for a disk brake

A disc brake and adjustment device technology, applied in the components of the brake, the type of the brake, the brake on the axial direction, etc., can solve the problem of large error, etc., and achieve the effect of reducing the increase of the error and saving the structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

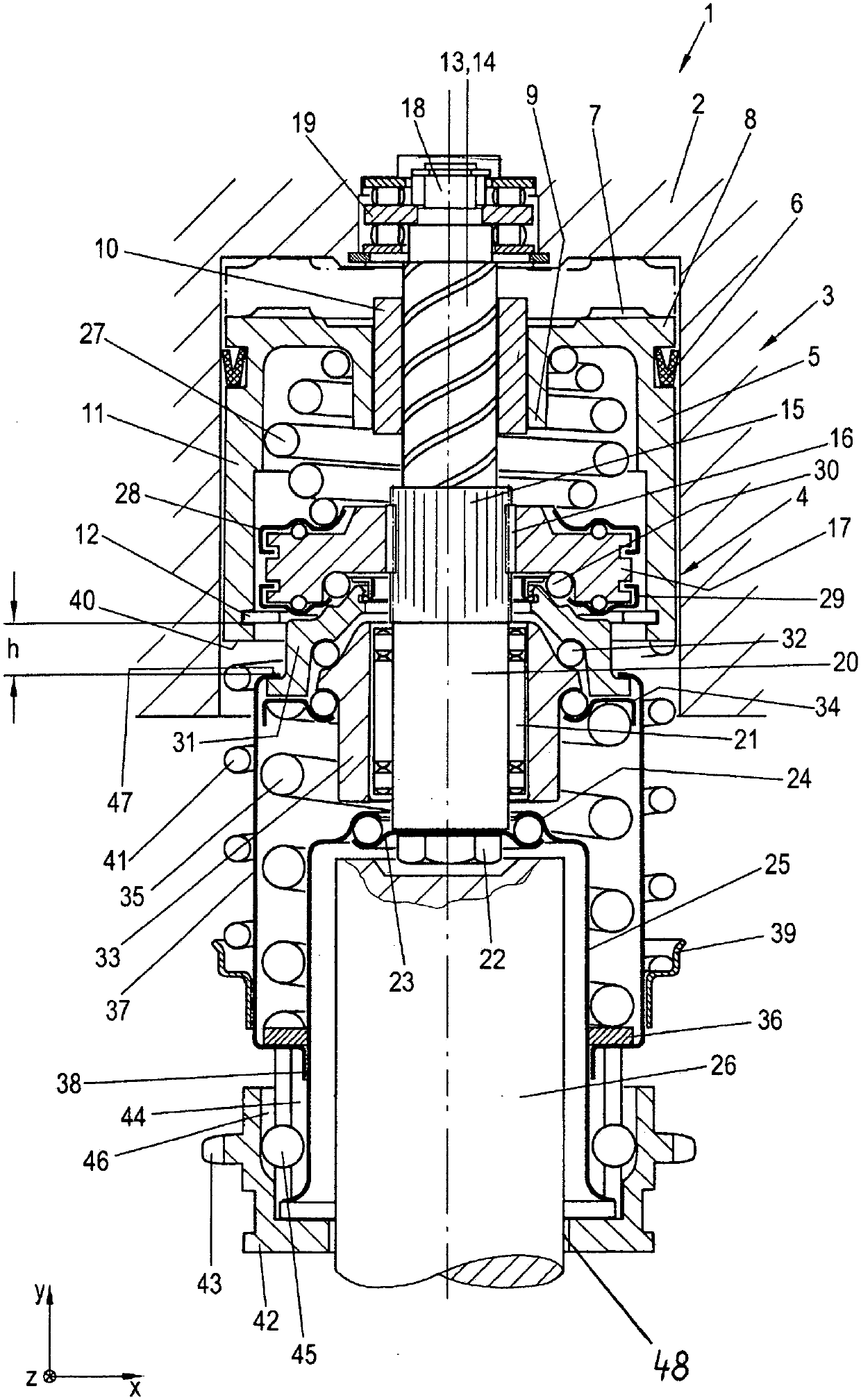

[0021] figure 1 A front sectional view of the adjustment device is shown. The adjusting device 1 is installed or can be installed in a brake caliper 2 of a (otherwise not shown here) disc brake which (in addition to the adjusting device or a plurality of adjusting devices therein) can for example It is designed in the manner of EP 1 546 571 B1, that is to say it has a pneumatically actuatable pressing device (not shown here) for pressing the brake during braking.

[0022] The adjusting device 1 has a pneumatically actuatable (ie can be acted upon with compressed air) actuator 3 . The adjusting device 1 can thus advantageously be activated independently of a brake actuation. The pneumatically actuatable actuator 3 has a cylinder 4 . Inserted in the cylinder 4 is a piston 5 which is axially displaceable in the cylinder 4 and can be acted upon by compressed air. The piston 5 has a seal 6 which is inserted into a groove in the piston 5 . Sealing member 6 will cylinder body 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com