3D mobile phone glass flat-grinding machine

A technology of flat grinding machine and glass, which is applied in the direction of grinding workpiece support, grinding drive device, grinding machine tool parts, etc., which can solve the problems of heavy weight, product fracturing, etc., and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

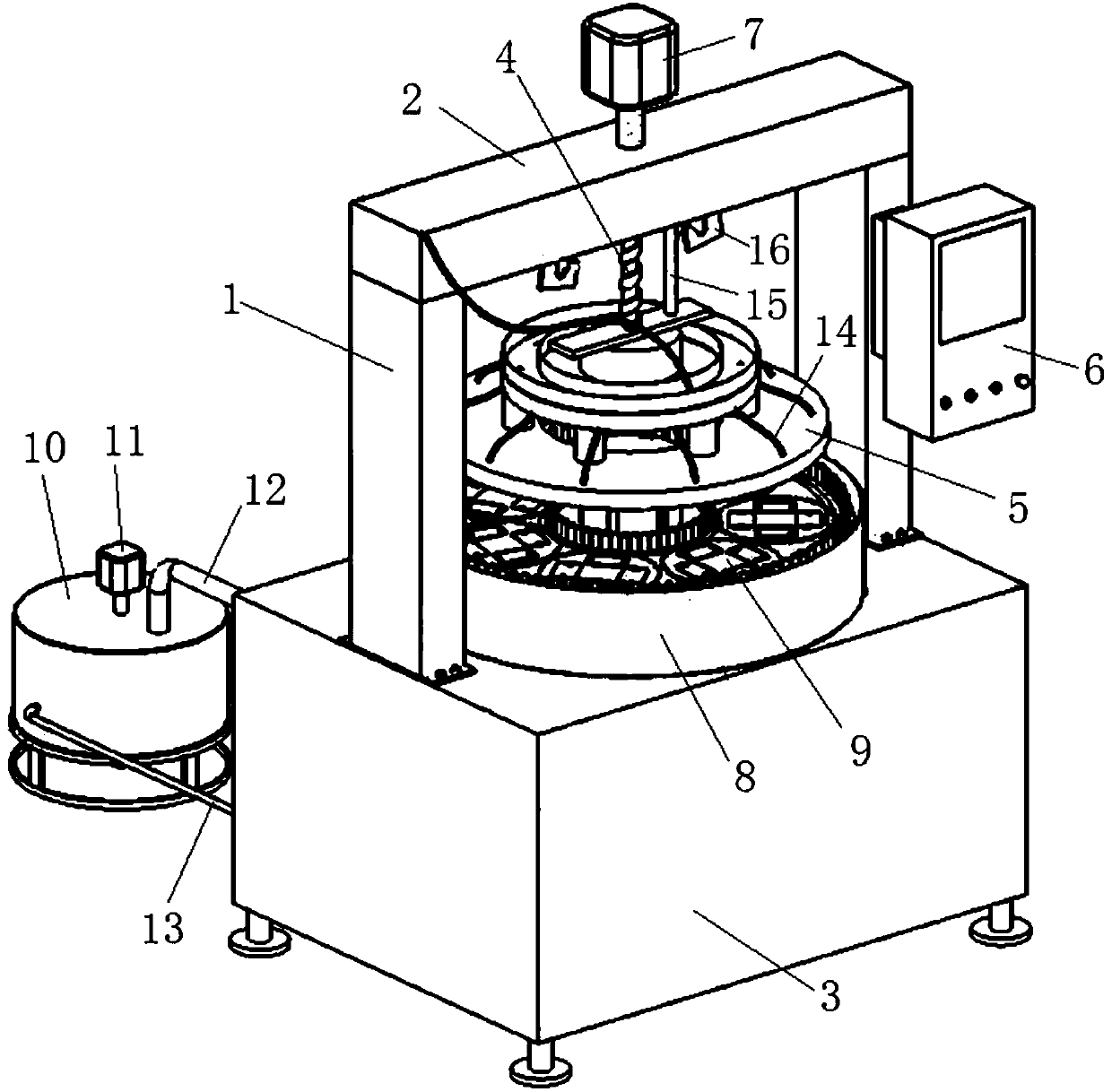

[0028] The specific implementation of the 3D mobile phone glass flat grinder of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] See attached figure 1 , The frame 1 of the flat mill is gantry-shaped, the top is a beam 2, and the frame 1 is installed on the top of the workbench 3. The beam 2 of the frame 1 is connected with the upper plate 5 through the lead screw 4, and the electric control box 6 is installed on the frame 1, and the control unit is arranged in the electric control box 6, and the control unit controls the servo motor 7 to drive the upper plate 5 vertically. A circular lower plate 8 is set on the workbench 3, and a 3D mobile phone glass 9 is set in the lower plate 8 through a jig. The upper wall 5 is located directly above the lower wall 8 . A polishing surface is provided under the upper plate 5, and the upper plate 5 and the lower plate 8 are driven to rotate relative to each other, and the polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com