Novel workpiece inner wall polishing device

A polishing device and workpiece technology, applied in the field of workpiece processing, can solve the problems of affecting the polishing quality, large clamping force, easy to produce shaking, etc., and achieve the effects of reducing labor intensity of workers, improving polishing efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

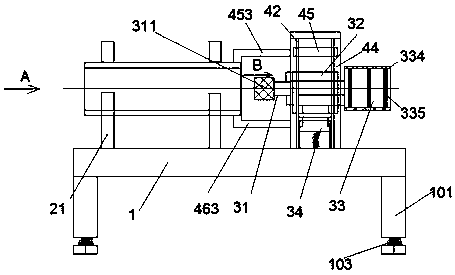

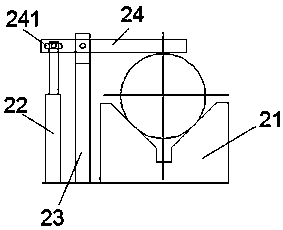

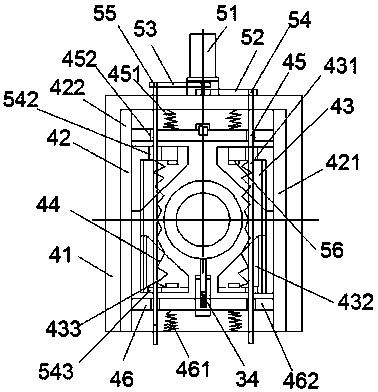

[0026] Such as Figure 1-Figure 8 As shown, a new workpiece inner wall polishing device of the present invention includes a manipulation frame 1, a clamping part, a polishing part and a clamping lock part, the clamping part is fixed on the upper surface of the manipulation frame 1, and the polishing part is installed In the middle of the clamping part, the clamping part is installed on the upper surface of the control frame on the right side of the clamping part and can be slid along the left and right directions. The bottom four corners of the control frame 1 are respectively provided with Standing corners 101, the bottom of each standing corner 101 is provided with a screw hole 102, and the inner thread of the screw hole 102 is connected with a screw corner block 103, through which the screw corner block 103 can be used when the ground is uneven. Lifting adjustment, so as to increase the stability of the support, the polishing part includes a casing 32, an adapter shaft 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com