Method for making super hard abrasive particles be arranged orderly in abrasive belt

A technology of superabrasives and abrasive belts, applied in abrasives, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of cumbersome arrangement of diamond particles, unsuitability for industrial production, low production efficiency, etc., and achieve Improve chip removal ability and workpiece processing quality, high production efficiency and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

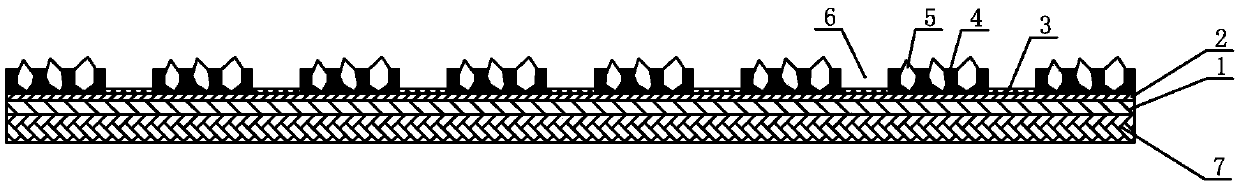

[0035] Such as figure 2 As shown, a abrasive belt in which superabrasive particles are arranged in an orderly manner on the grinding surface of the abrasive belt includes a substrate 1, a backing 7 is arranged on the lower surface of the substrate 1, and a backing 7 is arranged on the upper surface of the substrate 1. There is a pre-coating layer 2, and the pre-coating layer 2 is provided with a grinding working layer 4 and a photosensitive glue layer 3, wherein the grinding working layer 4 and the photosensitive glue layer 3 are arranged at intervals on the outer peripheral surface of the abrasive belt, and the grinding working layer 4 contains superabrasive particles 5, the height of the photosensitive adhesive layer 3 is lower than the grinding working layer 4, and the two adjacent grinding working layers 4 are placed between the two adjacent grinding working layers 4 The top end surface of the photosensitive adhesive layer 3 in between constitutes the chip removal groove ...

Embodiment 2

[0048] Repeat Example 1, the difference is:

[0049] In the step 3) of the preparation method, the photosensitive adhesive adopts Murakami photosensitive adhesive model AD20, and the coating thickness of the photosensitive adhesive is controlled to be 50 μm.

[0050] In step 4) of the preparation method, exposure is performed under a 2000W ultraviolet lamp for 1 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com