Annular rail guide vehicle active steering device adapting to different rail radii

A technology that adapts to different, active steering, applied in transportation and packaging, railway car body parts, axle self-adjustment and other directions, can solve the problems of reduced service life of wheels and guide rails, unfavorable equipment maintenance and maintenance, and reduced material transfer rate, etc. The effect of friction reduction, simple and reliable device structure, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, further illustrate the present invention.

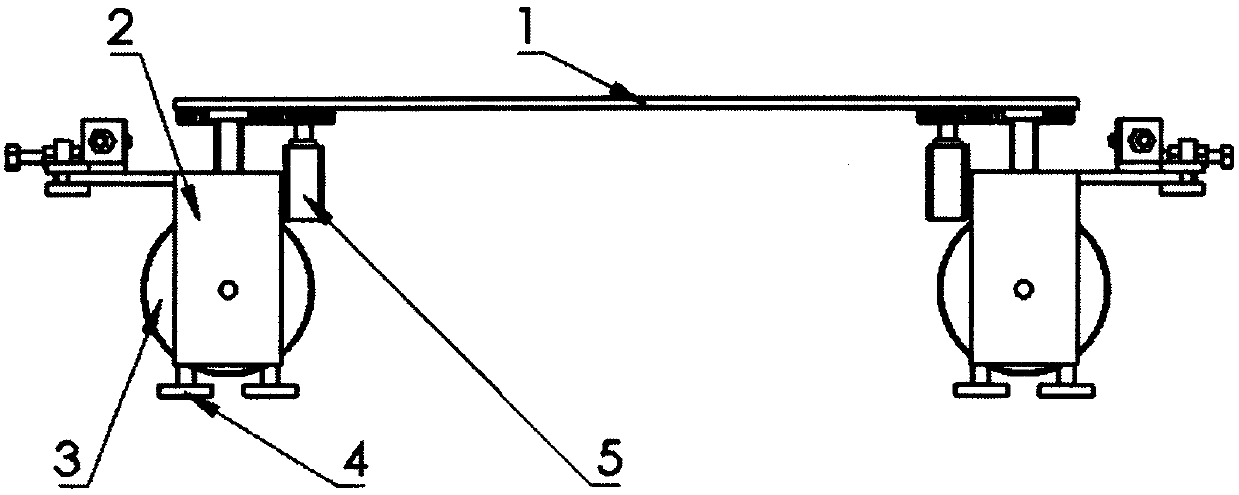

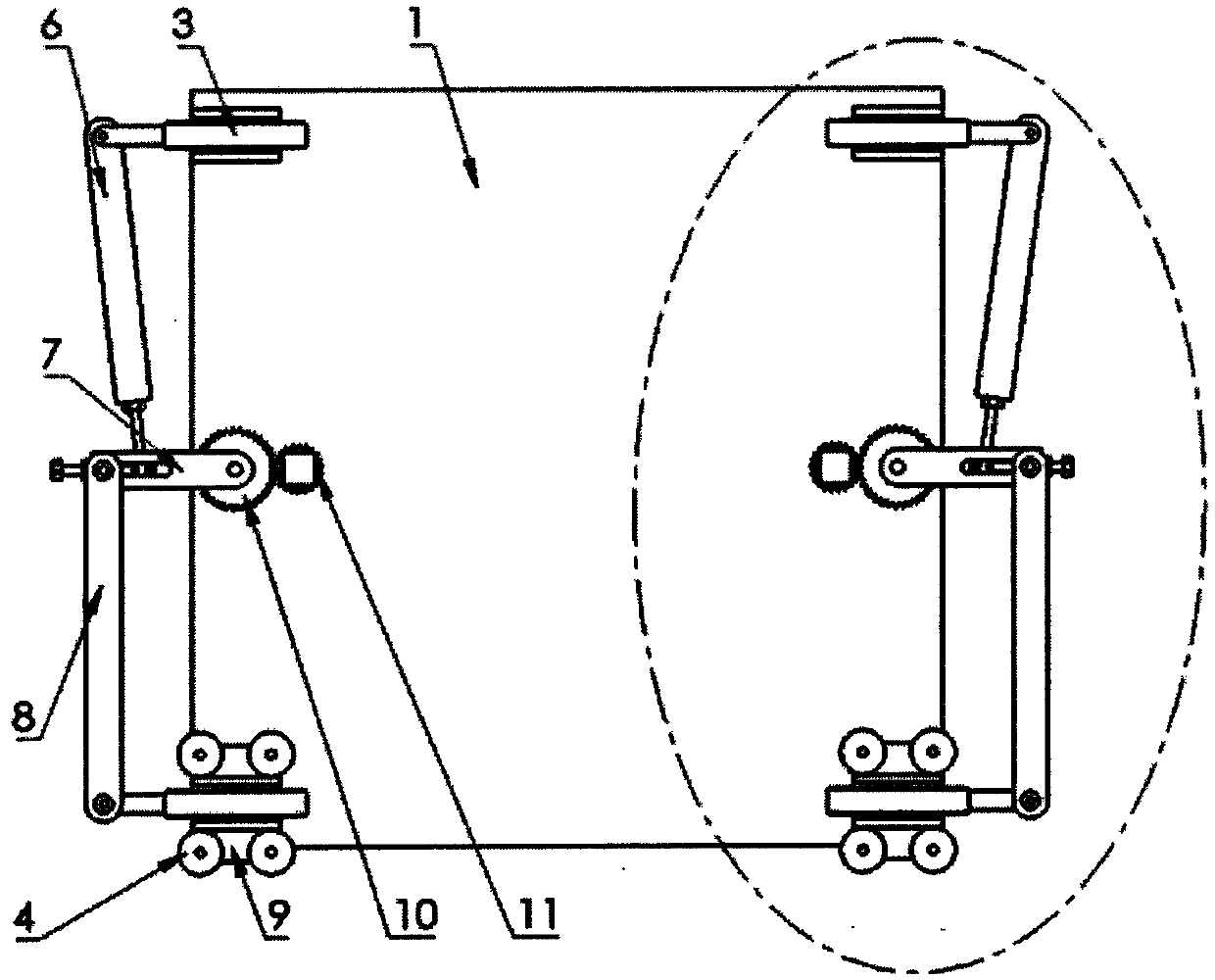

[0032] figure 2 and image 3 The front view and the bottom view of the active steering device of the circular shuttle adaptable to different track radii provided by this embodiment are respectively the front view and the bottom view. The active steering device of the circular shuttle adaptable to different track radius includes a frame 1 and two sets of steering units. Two sets of steering units are respectively connected to the front and rear parts of the vehicle frame 1 and are symmetrically distributed front and rear.

[0033] combine Figure 4 , the steering unit consists of a pinion 11, a bull gear 10, two wheels 3, two wheel brackets 2, an adjustable link assembly 6, a rocker assembly 7, a fixed-length link 8, a guide wheel bracket 9 and a guide wheel 4, etc. composition.

[0034] combine Figure 5 , The adjustable connecting rod assembly 6 is composed of a main rod 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com