Guard wall plate

A technology for wall panels and walls, which is applied in the direction of lighting and heating equipment, heating devices, dryers, etc., can solve the problems of reducing the service life of wall panels, achieve fast dehumidification, slow water seepage, and high safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

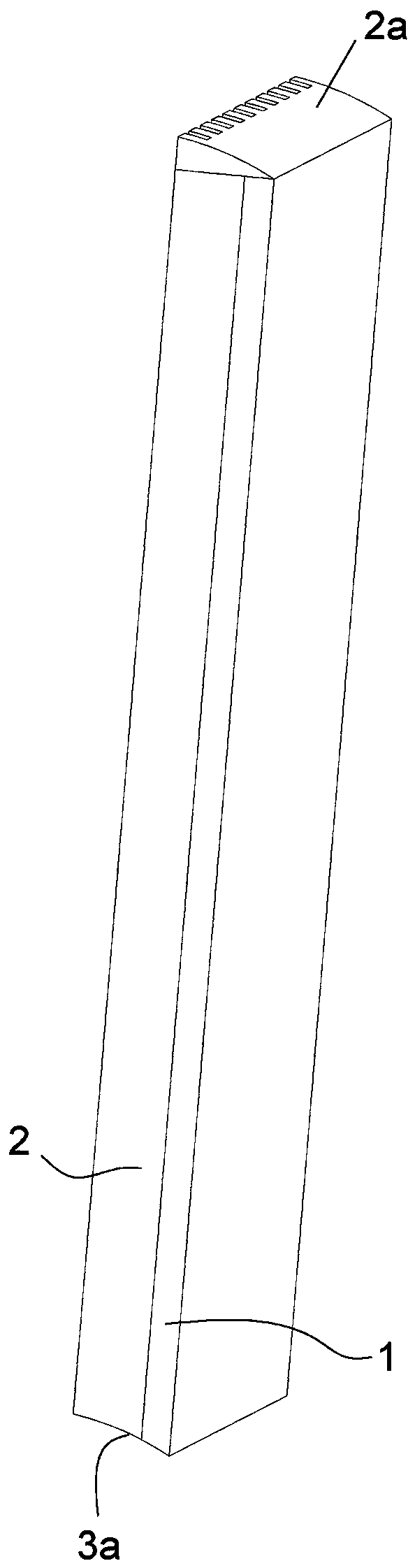

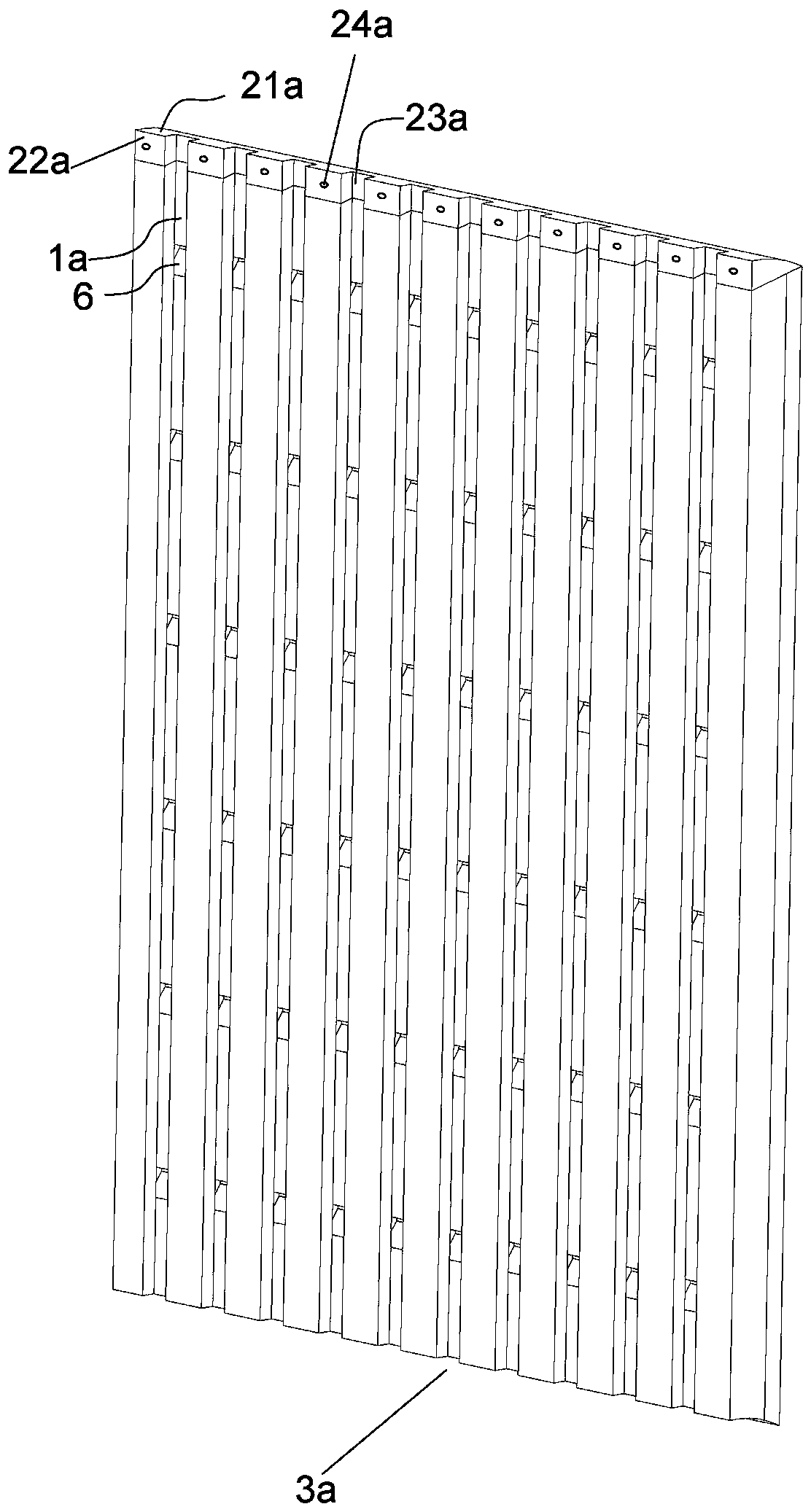

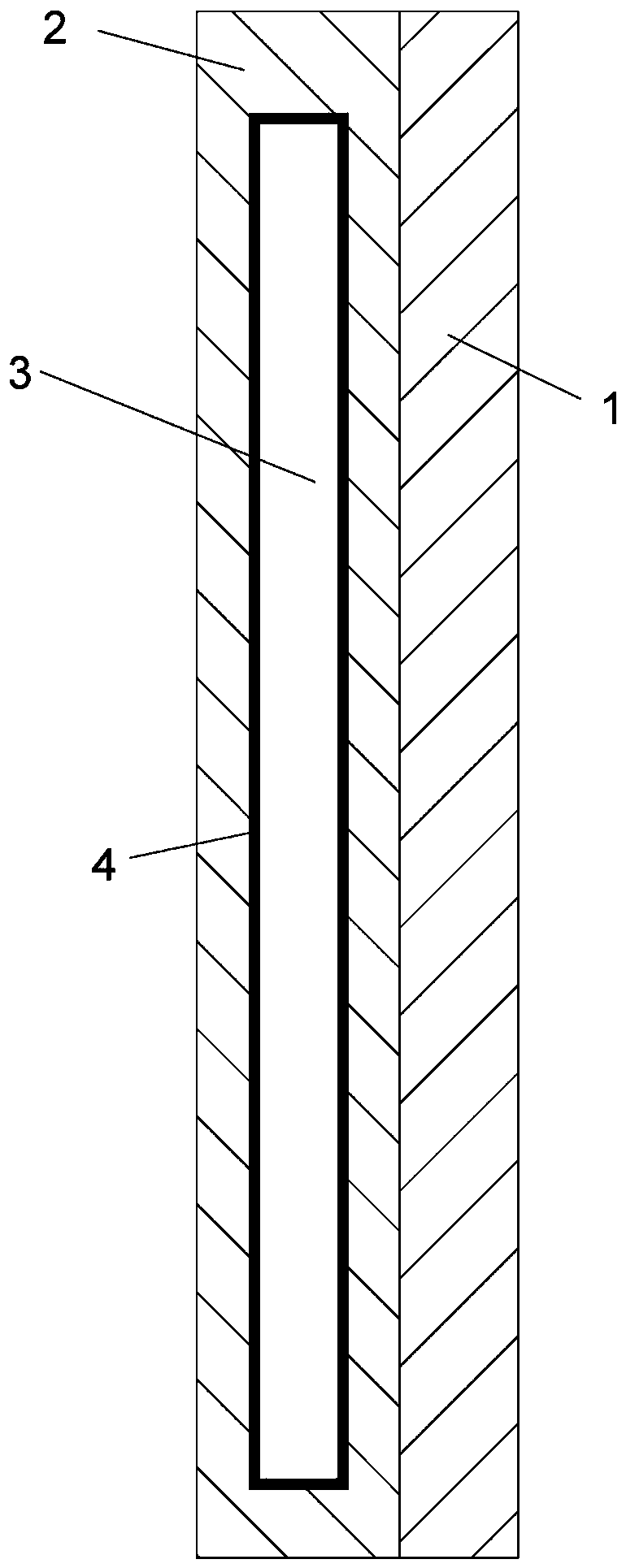

[0029] like Figure 1-6 As shown, a wall panel includes a decorative panel body 1 and an installation substrate 2 connected to the decorative panel body 1, the installation substrate 2 is attached to the wall and connected to the wall, and the upper surface of the installation substrate 2 The end face is provided with a heat dissipation chamber 3 that extends downwards and has a square cross-section. First heat conducting plates 4 are provided on the surrounding walls and the bottom of the chamber. The heat dissipation chamber 3 is provided with an electric heating device 5 ; The cooling cavity 3 is provided with a plurality of cooling holes 6 near the cavity wall of the wall, and the cooling holes 6 communicate with the side of the mounting substrate 2 near the wall, and the number of cooling holes 6 depends on the actual situation. To be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com