A composite insulating cross arm

A composite insulation and cross-arm technology, which is applied in the field of composite insulation cross-arm, can solve problems such as many dangerous points, unfavorable safety work, and complicated installation process, so as to improve safety performance and service life, facilitate safe work, and improve safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

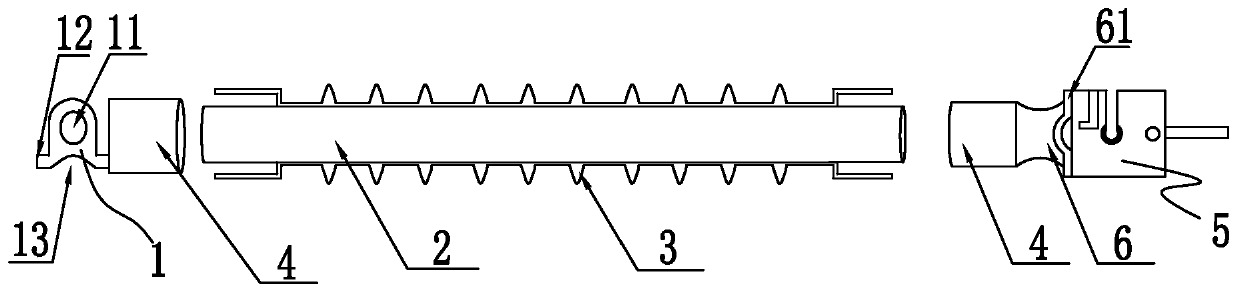

[0031] see figure 1 As shown, the present invention provides a composite insulating cross arm, comprising a mandrel 2, the mandrel 2 is a cylindrical structure, the outer surface of the mandrel 2 is provided with a rubber sheath 3; the two ends of the mandrel 2 are provided with There is a crimped cylinder clamp 4; one end of the cylinder clamp 4 is provided with a cavity that is matched with the mandrel 2, and the other end of the cylinder clamp 4 is closed; one of the cylinder clamps 4 is closed The side wall of the end is provided with a first connecting fitting 1 which is fixedly connected with it. The middle part of the first connecting fitting 1 is provided with an elliptical through hole 11, and the middle part of the top is provided with an arc-shaped groove 13; both sides of the top are provided with lugs 12, wherein The side wall of one lug 12 is fixedly connected to the cylindrical fixture 4; the closed end side wall of the other cylindrical fixture 4 is fixedly con...

Embodiment 2

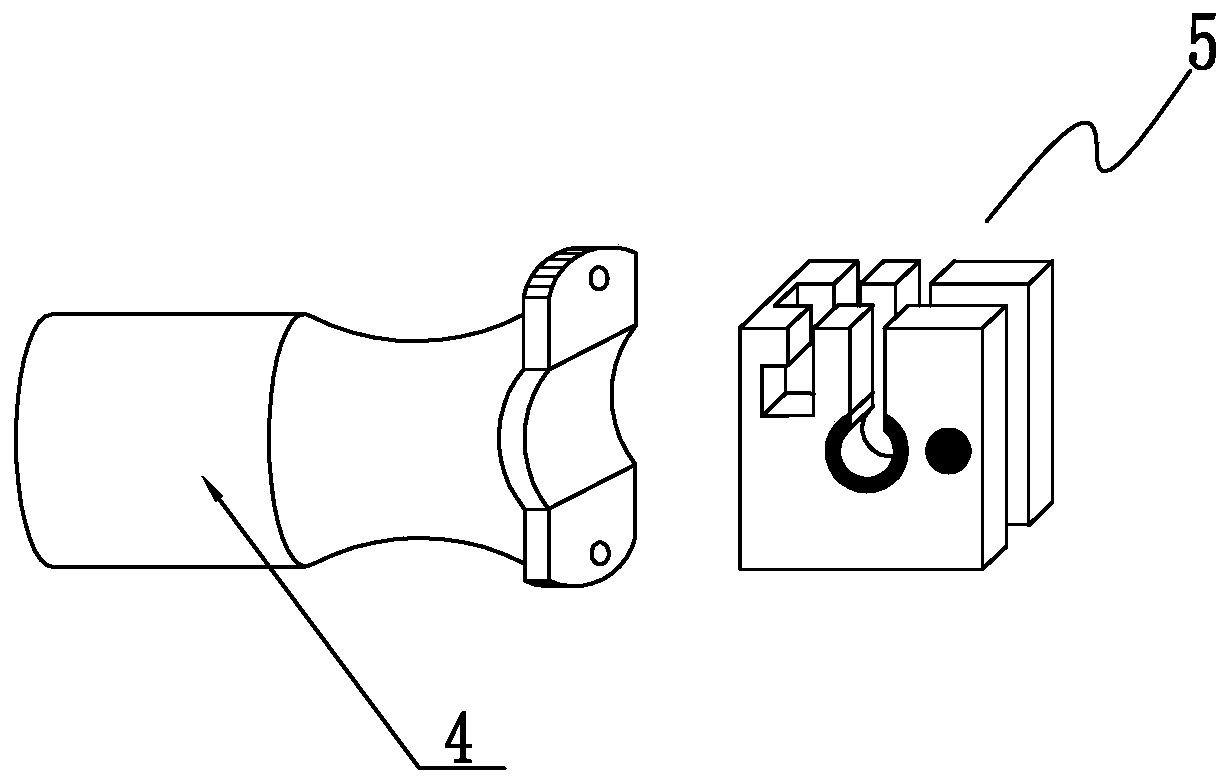

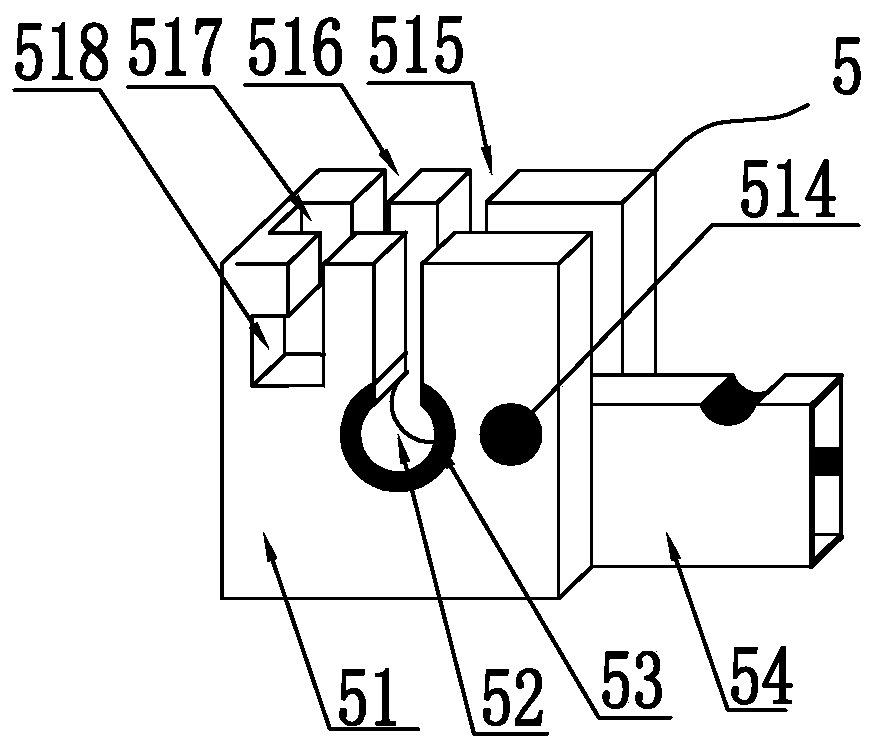

[0034] see figure 2 and image 3 As shown, as a technical optimization solution of the present invention, the lock assembly 5 includes a side plate 51 fixedly connected with the second connecting hardware 6; the middle part of the side plate 51 is provided with an arc-shaped wire hole running through the front and rear surfaces 52; the opening of the arc-shaped line hole 52 is upward; the opening of the arc-shaped line hole 52 is provided with a first vertical groove 515 penetrating to the top of the side plate 51; the side plate 51 is close to the cylinder clamp 4 One end of the first vertical groove 515 is also provided with a second vertical groove 516 parallel to the first vertical groove 515; the bottom of the second vertical groove 516 extends toward the direction of the cylinder clamp 4 to pass through the front and rear surfaces of the side plate 51 and is in line with the The card slot 518 connected with the second vertical groove 516; the middle part of the side pl...

Embodiment 3

[0037] see Figure 4 As shown, as a technical optimization solution of the present invention, the top of the rotating clamping plate 54 is provided with a crimping groove 513 matching the arc-shaped wire hole 52; A first cavity 520 is opened, and a connecting seat 58 is slidably connected inside the first cavity 520; a fixing plate 510 is provided on the outside of the connecting seat 58; The slot 518 matches the block 511; the bottom of the fixing plate 510 is provided with a push-pull assembly; the crimping slot is for fixing the wire.

[0038] When in use, put the wires directly from the top of the first vertical slot into the arc-shaped slot, then hold the push-pull assembly and turn the fixing plate into the horizontal slot to press the crimping slot on the wires in the arc-shaped slot, and then Push the push-pull assembly, the fixed plate moves to the direction of the card slot, and drives the connecting seat to move to the direction of the card slot. At this time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com