Dry distillation circulating fluidized bed boiler

A technology of circulating fluidized bed and dry distillation furnace, applied in the field of boilers, which can solve the problems of severe smog, difficulty in storage and transportation, serious air pollution, etc., and achieve the effects of high comprehensive benefits, efficient utilization, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

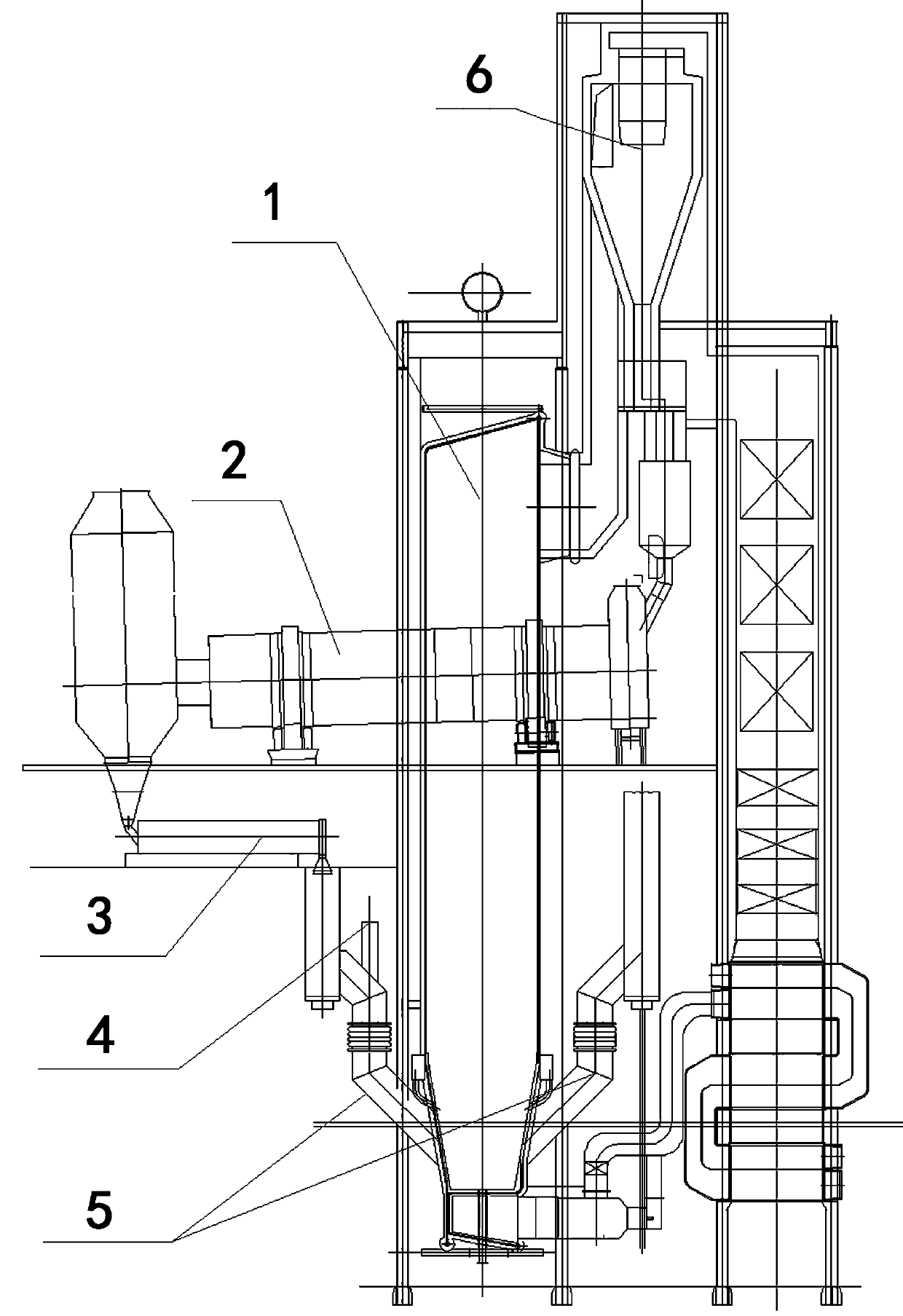

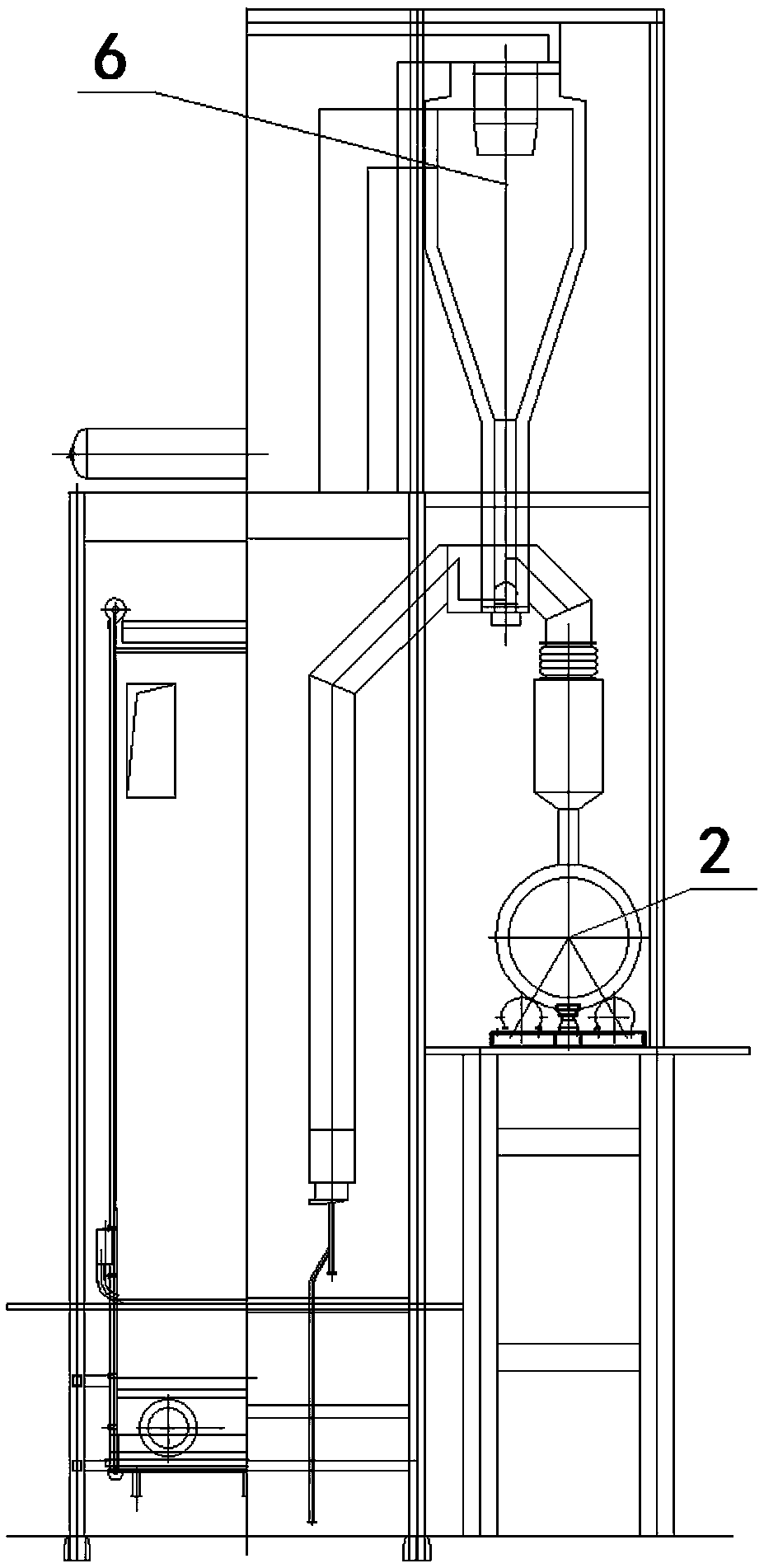

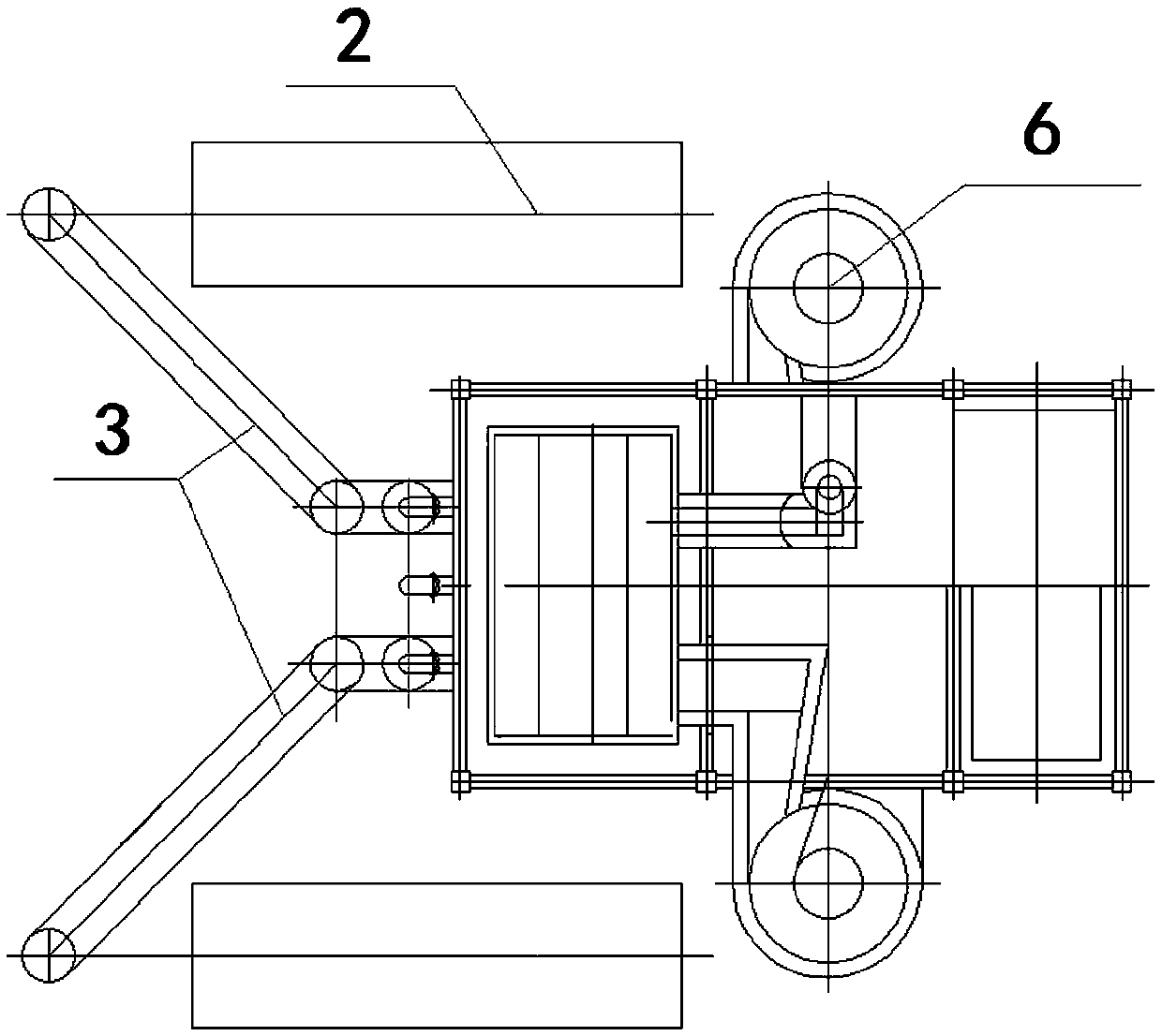

[0018] see Figure 1 to Figure 4 , comprising a furnace 1, a pot and a cyclone separator 6, a dry distillation cylinder 2 is set between the cyclone separator 6 and the furnace 1, the return ash of the cyclone separator 6 enters the dry distillation cylinder 2 and mixes with lignite and undergoes carbonization, and the dry distillation Lignite is burned to furnace 1.

[0019] The cyclone separator 6 is a horizontal or vertical adiabatic cyclone separator; a feeder 5 is provided before the lignite enters the furnace 1, and the dry distillation cylinder 2 adopts a horizontal cylinder structure.

[0020] The roller conveyor 3 sends the dry-distilled lignite to the feeder, and then burns in the furnace. When the boiler is ignited, the required fuel is input from the starting fuel inlet 4.

[0021] The dry distillation process is as follows: using a circulating flow flower bed boiler to circulate high temperature 850~900 °C return ash and lignite in the dry distillation furnace t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap