W-shaped heat storage type radiant tube

A regenerative radiant tube and radiant tube technology, applied in the field of radiant tubes, can solve the problems of reducing the service life of radiant tubes, uneven surface temperature of radiant tubes, affecting the heating capacity and heating quality of radiant tubes, etc., and achieve good economic and social Effect, improve service life, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

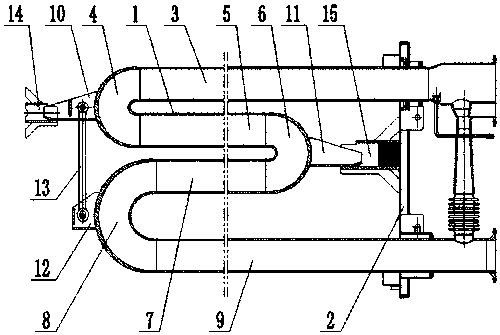

[0010] Below in conjunction with accompanying drawing, the present invention is further described;

[0011] In the accompanying drawings: a W-shaped heat storage radiant tube, the radiant tube includes a W-shaped tube body 1 and a radiant tube cover 2; the W-shaped tube body 1 includes straight tubes A3, curved Head B4, straight pipe C5, elbow D6, straight pipe E7, elbow F8 and straight pipe G9 are fixed together by welding; the left side of the elbow B4 is welded with a support H10, and the elbow D6 The right side of the elbow F8 is welded with a support I11, and the left side of the elbow F8 is welded with a support J12; the support H10 and the support J12 are connected and fixed by a connecting rod 13; the left side of the support H10 is located on the inner support K14 of the furnace wall, The right side of the support I11 is located on the support L15, and the support L15 is welded on the radiant tube cover 2, and the W-shaped tube body 1 can be freely expanded and contra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com