CIGS film solar cell air heater

An air heater and film technology, applied in the direction of air heaters, fluid heaters, electrical components, etc., can solve the problems of low heat utilization efficiency, large insulation part volume, high protection requirements, etc., to improve the efficiency of photoelectric replacement and construction Good environment and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

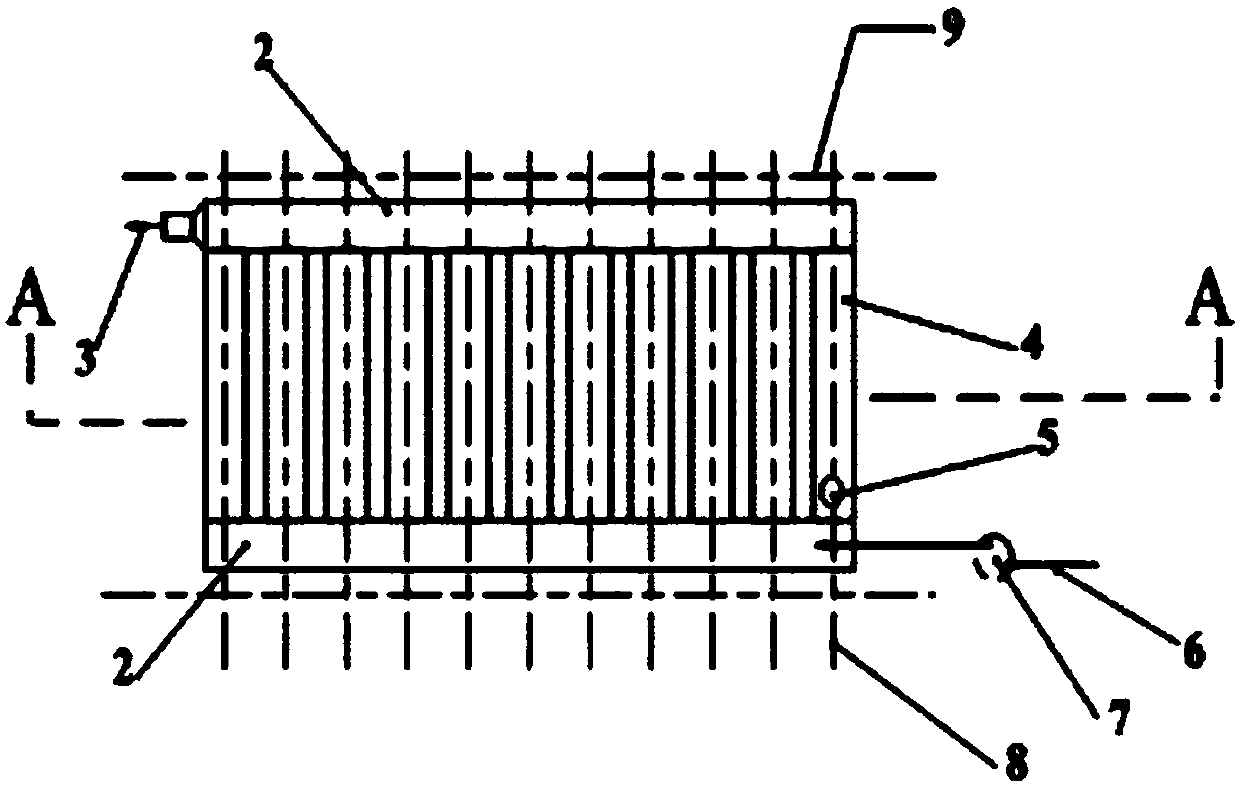

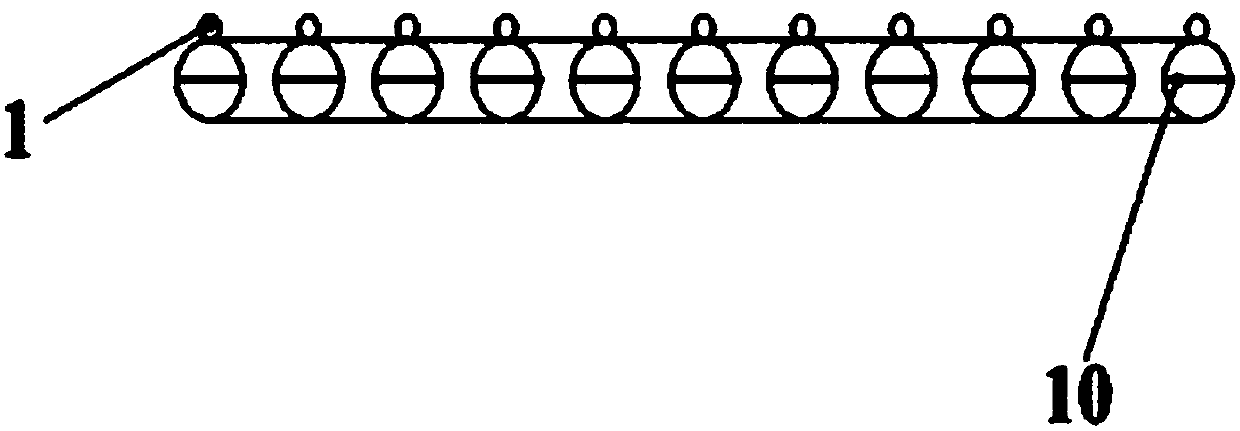

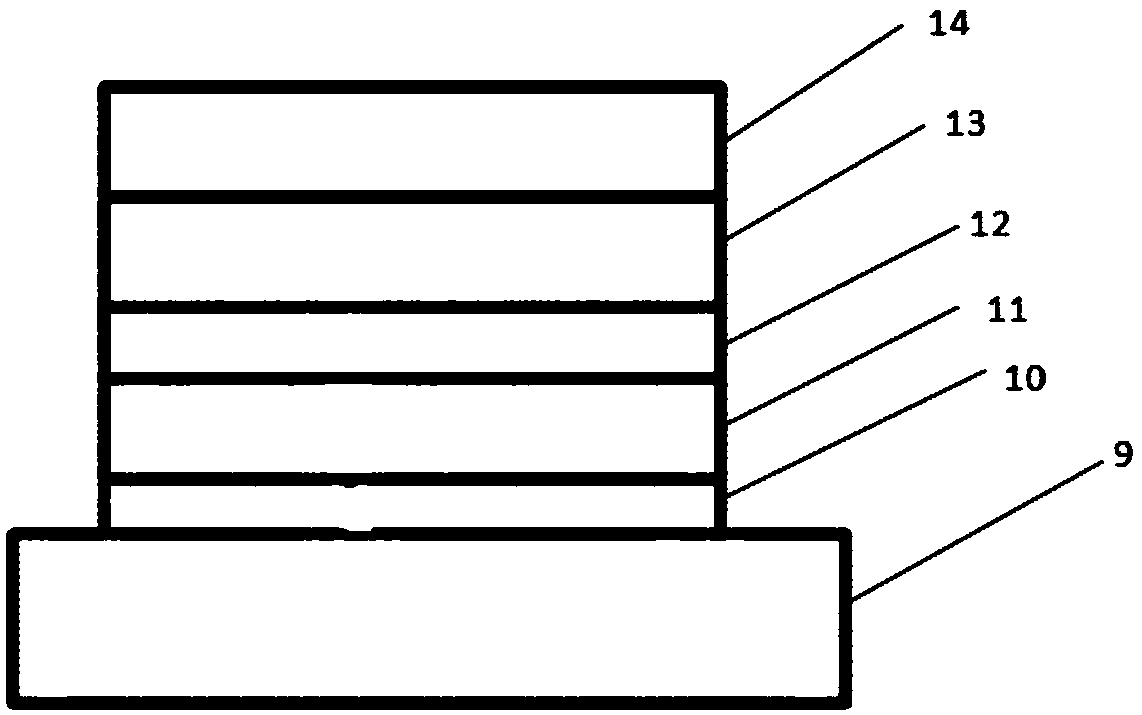

[0020] A solar air heater, comprising an inflatable plastic mold cavity, a hot air outlet 3 and an air inlet 6, one end of the inflatable plastic mold cavity is connected to the hot air outlet 3, and the other end of the inflatable plastic mold cavity One end is connected with the air inlet 6. The inflatable plastic mold cavity comprises at least two or more cylindrical transverse transparent plastic films 2 and at least two or more cylindrical vertical transparent plastic films 4, the transverse transparent plastic films 2 and the vertical transparent plastic films 4 intertwined with each other. Both the horizontal transparent plastic film 2 and the vertical transparent plastic film 4 are provided with a black plastic film 10 . The heater also includes a horizontal installation rope 9 and a vertical installation rope 8, the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com