Heat conduction oil furnace real-time monitoring and intelligent alarm system

A technology of intelligent alarm and heat-conducting oil furnace, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as abnormal pressure, instability, and insufficient natural gas pressure in heat-conducting oil pipelines, and achieve clear The effect of expressing failure problems, simple and quick installation, and low post-production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

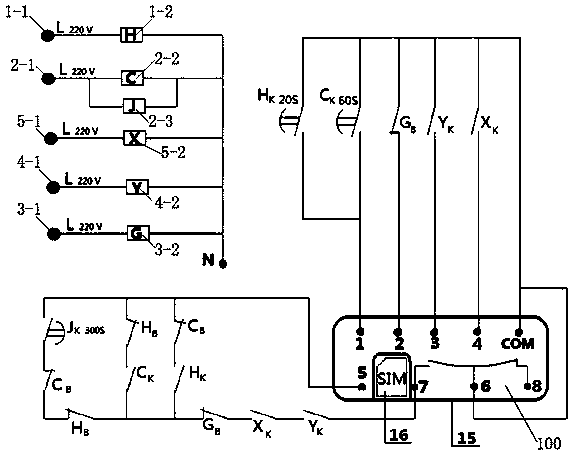

[0027] This embodiment provides a reliable, effective and stable method to solve the ability effects that cannot be realized by humans, and to achieve the best working state of the thermal oil furnace real-time monitoring intelligent alarm system. First of all, it should be pointed out that figure 1 1, 2, 3, 4, and 5 are the 5 monitoring positions of the intelligent alarm module 100, 6 is the input common terminal, 6-7 are the normally open auxiliary contacts, and 6-8 are the normally closed auxiliary contacts. Contacts, COM is the common source signal of the intelligent alarm, L220V is the output 220V power supply of each indicator light, N is the neutral terminal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com