Method for testing rod body surface shear stress of total-length bonding reinforcing steel bar anchor rod

A testing method and a technology of shear stress, which are applied in the measurement, force measurement, and measurement device of the change force of the optical properties of the material when it is stressed, can solve the problem of easy falling off of the strain gauge, low spatial resolution, and inability to anchor the steel bar To solve problems such as the monitoring of rod working properties, achieve the effect of strong anti-electromagnetic field interference, simple testing process, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

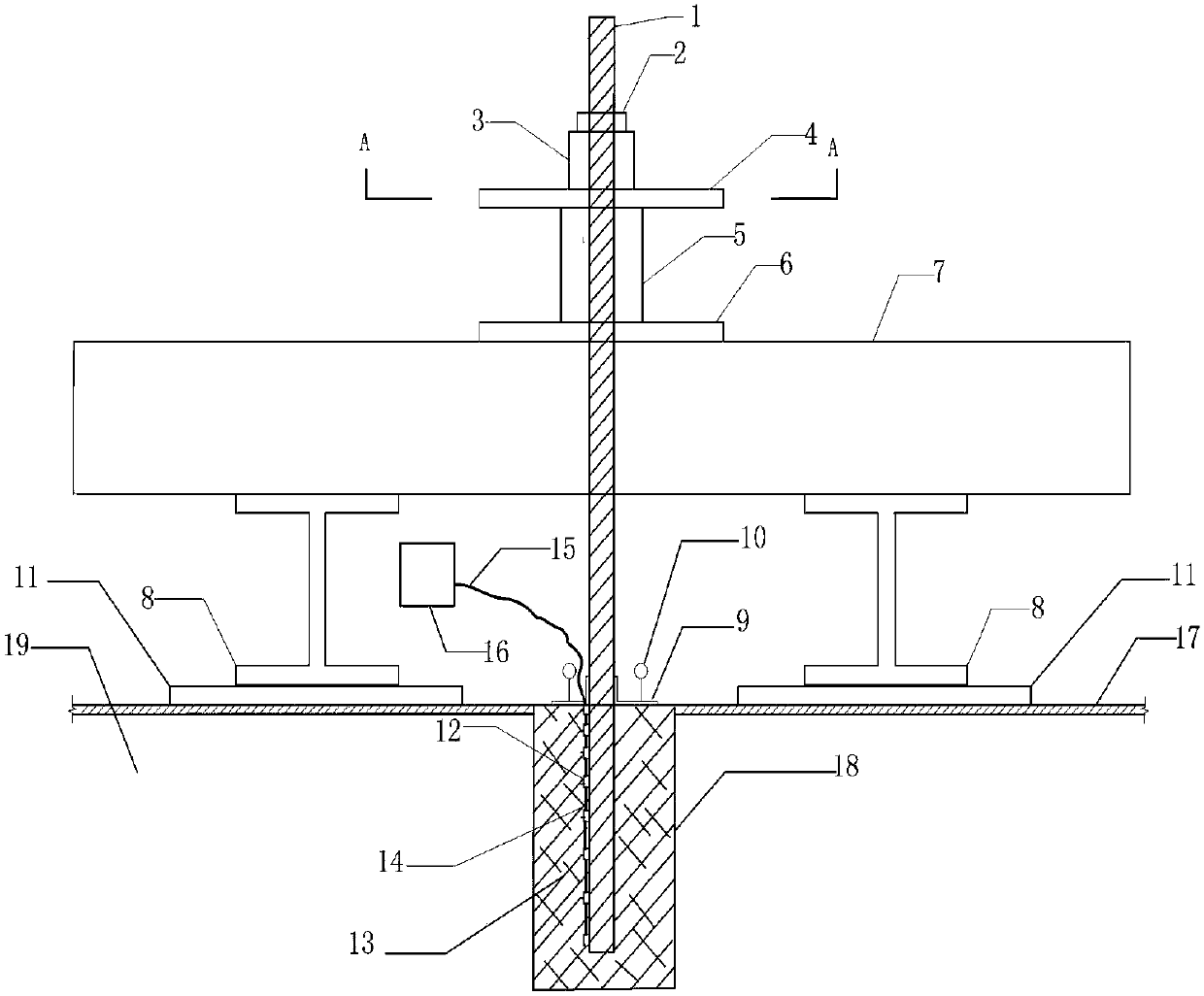

[0027] This embodiment adopts the surface shear stress testing device of the full-length bonded steel anchor rod to realize, and the specific process is as follows:

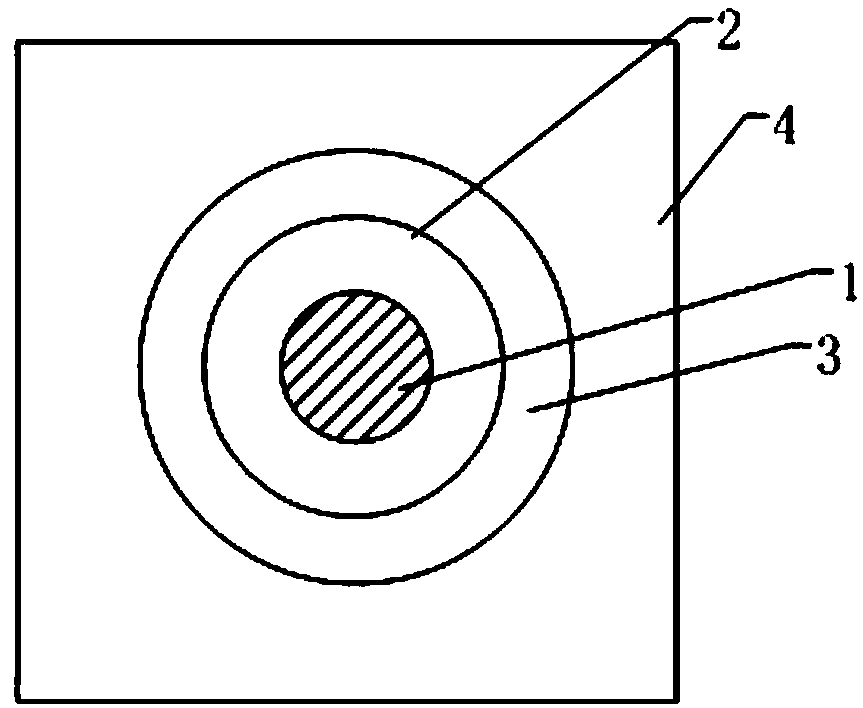

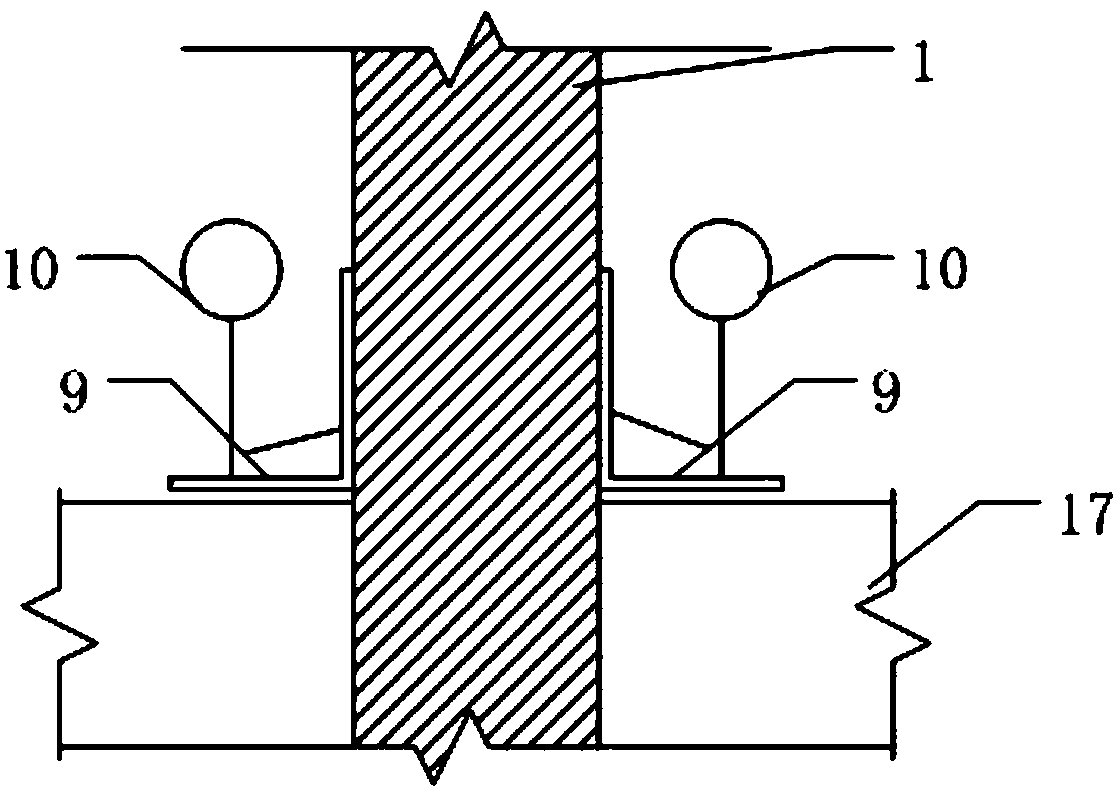

[0028](1), according to the shear stress test section of the anchor rod body 1, determine the position of the low temperature sensitive miniature fiber grating strain sensor 12, and engrave the low temperature sensitive miniature fiber grating strain sensor 12 into the optical fiber 14 to form a fiber grating sensor string. The sensor near the top of the rod hole is relatively dense), and the miniature clamping blocks at each low-temperature-sensitive miniature optical fiber grating strain sensor 12 two ends are welded on the anchor rod body 1 respectively, so that the low-temperature-sensitive miniature optical fiber grating strain sensor 12 and the anchor rod The rod body 1 is integrated to ensure that the two are deformed synchronously after being stressed, and the optical fiber 14 at the end of the anchor rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com