Polaroid, manufacturing method thereof, and liquid crystal display panel

A production method and technology of polarizers, which are applied in polarizing components, optics, instruments, etc., can solve problems such as inability to exert linear polarization characteristics, and achieve the effects of improving display effects, extending standby time, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

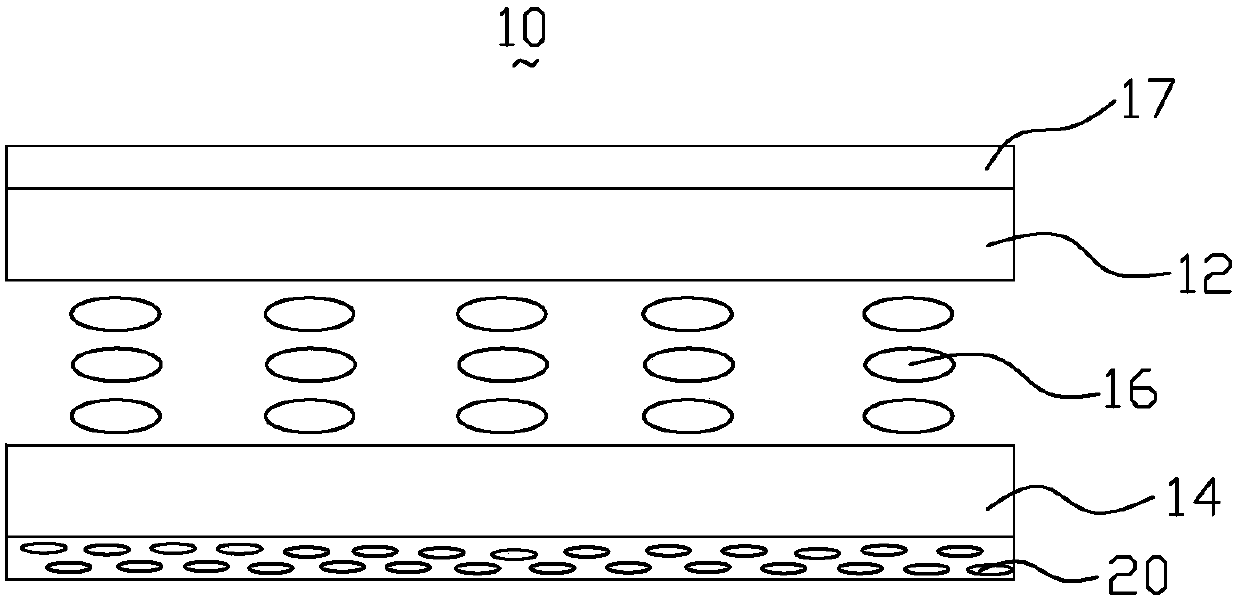

[0028] Due to the directivity of quantum rods and the ability to emit linearly polarized light, the film layer of quantum rods can convert almost all the light passing through this layer into polarized light, which can avoid the loss of light caused by the use of polarizers and improve the utilization rate of backlight , and at the same time, the brightness of the display panel can be increased to realize image display with high brightness and high color gamut.

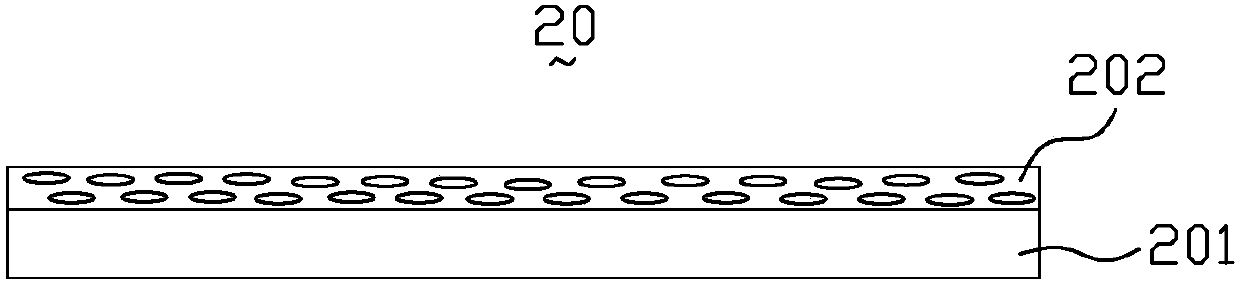

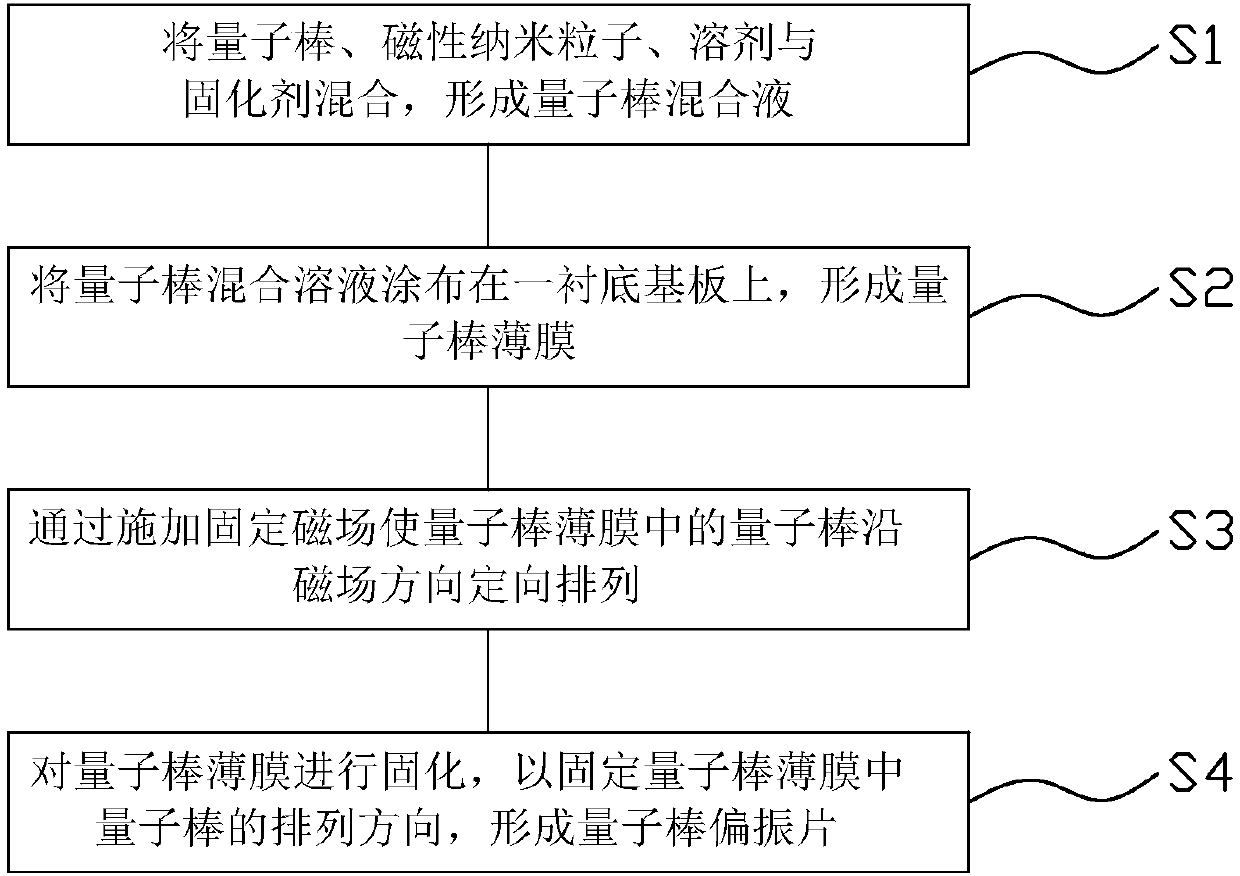

[0029] figure 1 A schematic cross-sectional view of a polarizer provided in an embodiment of the present invention. see figure 1 , a polarizer 20 includes a base substrate 201 and a quantum rod thin film 202 disposed on the base substrate 201, the quantum rod thin film 202 includes a plurality of quantum rods arranged in the same direction, wherein the quantum rods are doped with magnetic nanoparticles .

[0030] Optionally, the quantum rods in the quantum rod film 202 are one or more of II-VI, III-V, I-III-VI or I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com