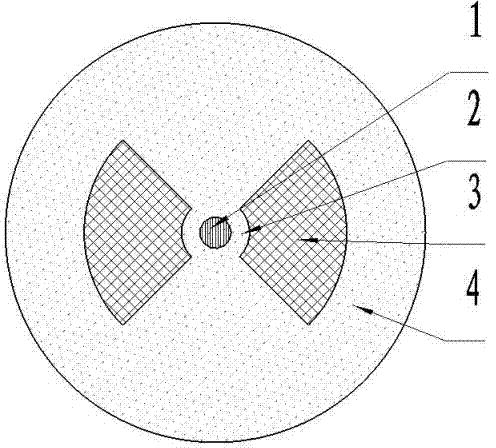

Method for making bow-shaped polarization maintaining optical fiber for Y waveguide

A technology for polarization-maintaining optical fiber and manufacturing method, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc. It can solve the problems of easy cracking and large thermal expansion coefficient in the stress area, etc., and achieve good mechanical strength and good optical fiber structure symmetry , The effect of stable polarization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

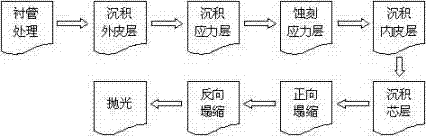

[0031] (1) if figure 2 The pretreatment of the liner on the MCVD lathe is shown;

[0032] (2) Using the MCVD process to deposit the outer skin layer, deposit the stress layer, etch the stress layer, deposit the inner skin layer, deposit the core layer, forward collapse, reverse collapse, polishing and other processes to prepare the bow-tie type polarization maintaining optical fiber preform, optical fiber The outer diameter of the preform is 11.2mm, and the ratio of germanium and boron is 6:1. The total amount of germanium and boron will be 50% of the traditional polarization-maintaining optical fiber material;

[0033] (3) Then draw the polarization-maintaining optical fiber preform into a polarization-maintaining optical fiber with a diameter of 80.5 μm on a wire drawing tower. Two layers of light-cured coatings are used to protect the optical fiber. Finally, a polarization-maintaining optical fiber with a fiber-coated diameter of 173 μm is obtained, and the refraction in ...

Embodiment 2

[0035] (1) if figure 2 The pretreatment of the liner on the MCVD lathe is shown;

[0036] (2) Using the MCVD process to deposit the outer skin layer, deposit the stress layer, etch the stress layer, deposit the inner skin layer, deposit the core layer, forward collapse, reverse collapse, polishing and other processes to prepare the bow-tie type polarization maintaining optical fiber preform, optical fiber The outer diameter of the preform is 19.8mm, the ratio of germanium and boron is 5:1, and the total amount of germanium and boron will be 50% of the traditional polarization-maintaining optical fiber material;

[0037] (3) Then the polarization-maintaining optical fiber preform is drawn into a polarization-maintaining optical fiber with a diameter of 80.5 μm on a drawing tower. The drawing temperature is 2000°C, the drawing tension is 44g, and the drawing speed of the optical fiber is 84m / min. Two layers of light-cured coatings are used to protect the optical fiber, and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com