Multistage telescopic electric cylinder

An electric cylinder and cylinder barrel technology, which is applied in the transmission field, can solve the problems of excessive bearing size, difficult assembly, and restricting the development of small-sized multi-stage electric cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An embodiment of the present invention provides a multi-stage telescopic electric cylinder. The multi-stage telescopic electric cylinder includes: a cylinder, and the electric cylinder also includes: an N-stage transmission mechanism arranged in the cylinder and sequentially sleeved, wherein, N≥ 2. N is a natural number; the number of stages of the electric cylinder is N stages.

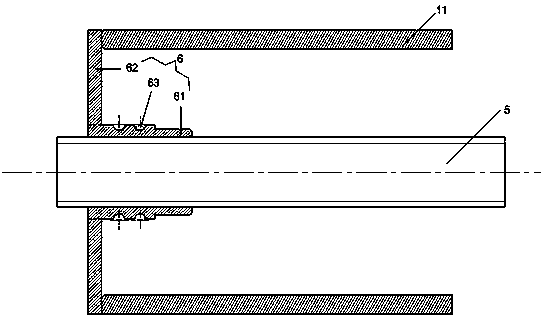

[0033] Each stage of transmission mechanism includes: lead screw, push rod and nut. Each level of nut includes: a body provided with an internal thread and an extension part arranged at the end of the body, and the extension part surrounds the opening of the body. The body is sleeved on the lead screw. The end of the extension part is fixedly connected with one end of the push rod.

[0034] Except for N-level nuts, the outer surface of the nut body of each level is provided with multiple outer annular raceways; except for the first-level screw, the inner surface of each level of screw is pro...

Embodiment 2

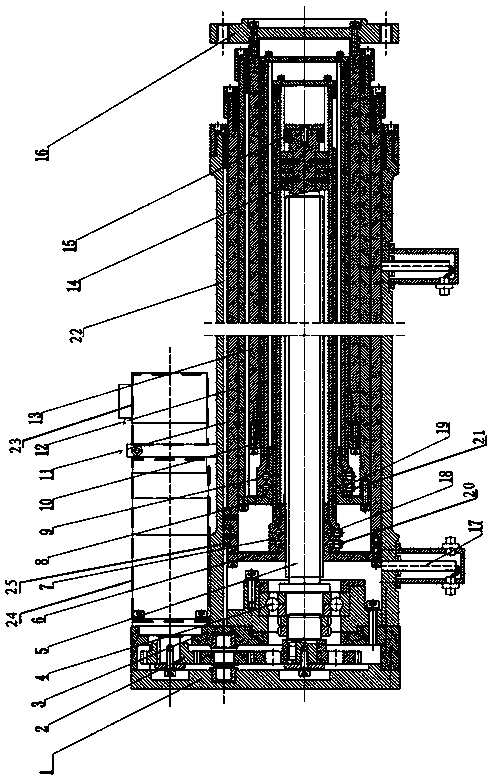

[0056] In order to illustrate the multi-stage telescopic electric cylinder provided by the present invention in more detail, a three-stage telescopic electric cylinder is taken as an example for specific description below.

[0057] refer to figure 1 As shown, the three-stage telescopic electric cylinder includes: a cylinder 22, and a three-stage transmission mechanism arranged in the cylinder 22 and sequentially sleeved, wherein the first-stage transmission mechanism includes: a first-stage lead screw 5, a first-stage The first stage push rod 11 and the first stage nut 6, the second stage transmission mechanism includes: the second stage lead screw 7, the second stage push rod 12 and the second stage nut 8, the third stage transmission mechanism includes: the third stage lead screw 9. The tertiary push rod 13 and the tertiary nut 10.

[0058] Each level of nut includes: a body provided with an internal thread and an extension part arranged at the end of the body, and the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com