A method of winding compensation in via holes

A wire winding and hole wall technology, which is applied in the direction of electrical connection of printed components, printed circuit components, printed circuits, etc., can solve the problems of limited parts and wiring space, sacrifice of layout and wiring space, and unfavorable parts and signal layout and wiring, etc. , to improve space utilization, reduce signal transmission delay, and optimize board performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

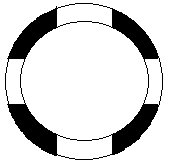

[0030] like figure 2 As shown, it is an ordinary via hole on the PCB, the inner ring is a drill hole, and the black circle means that the copper ring runs through the PCB board up and down, and has conductive properties.

[0031] like image 3 , 4 As shown, a method of winding compensation in the via through hole, in the design of the PCB board, uses the via through hole that penetrates up and down in the PCB board, and wires are routed up and down the hole wall to perform winding compensation, reducing the winding on the board surface. Line space, so as to achieve the purpose of improving the utilization rate of the board and optimizing the performance of the board.

Embodiment 2

[0033] On the basis of embodiment 1, the implementation steps of the method described in this embodiment include:

[0034] Select the signal via hole that needs winding compensation, and perform up and down winding in the through hole;

[0035] During the production of the PCB board factory, the copper wires wound up and down in the via holes are corroded and developed.

Embodiment 3

[0037] On the basis of embodiment 1 or 2, the implementation steps of the method described in this embodiment also include:

[0038] Fill the via hole with resin to protect the copper wire in the hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com