Flushing-scrubbing type tableware washing machine

A tableware cleaning and cloth cover technology, applied in the field of cleaning tools, can solve problems such as inconvenience, loss of running water, waste of resources, etc., and achieve the effects of improving cleaning quality, reducing bending degree, and saving time in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

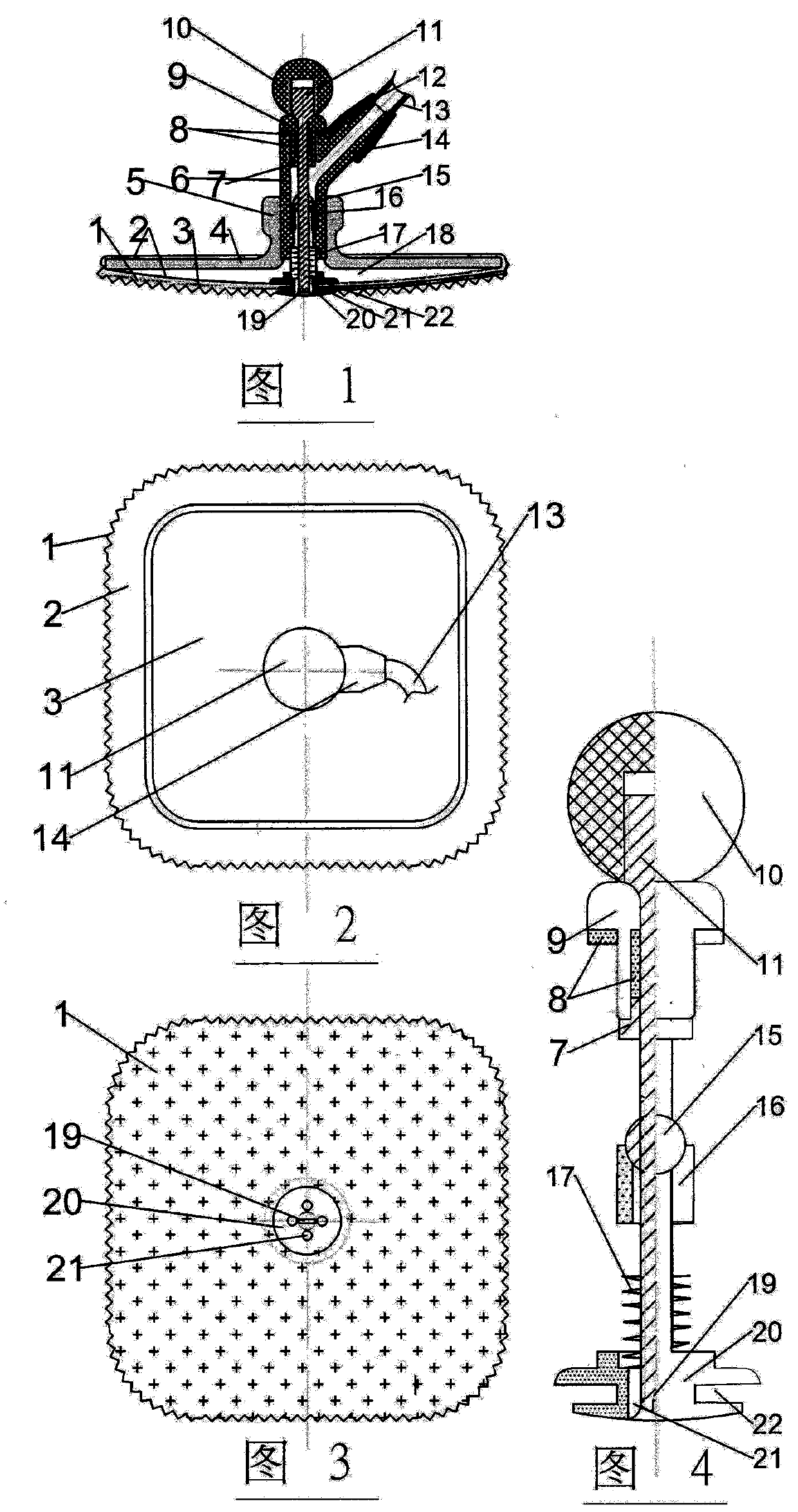

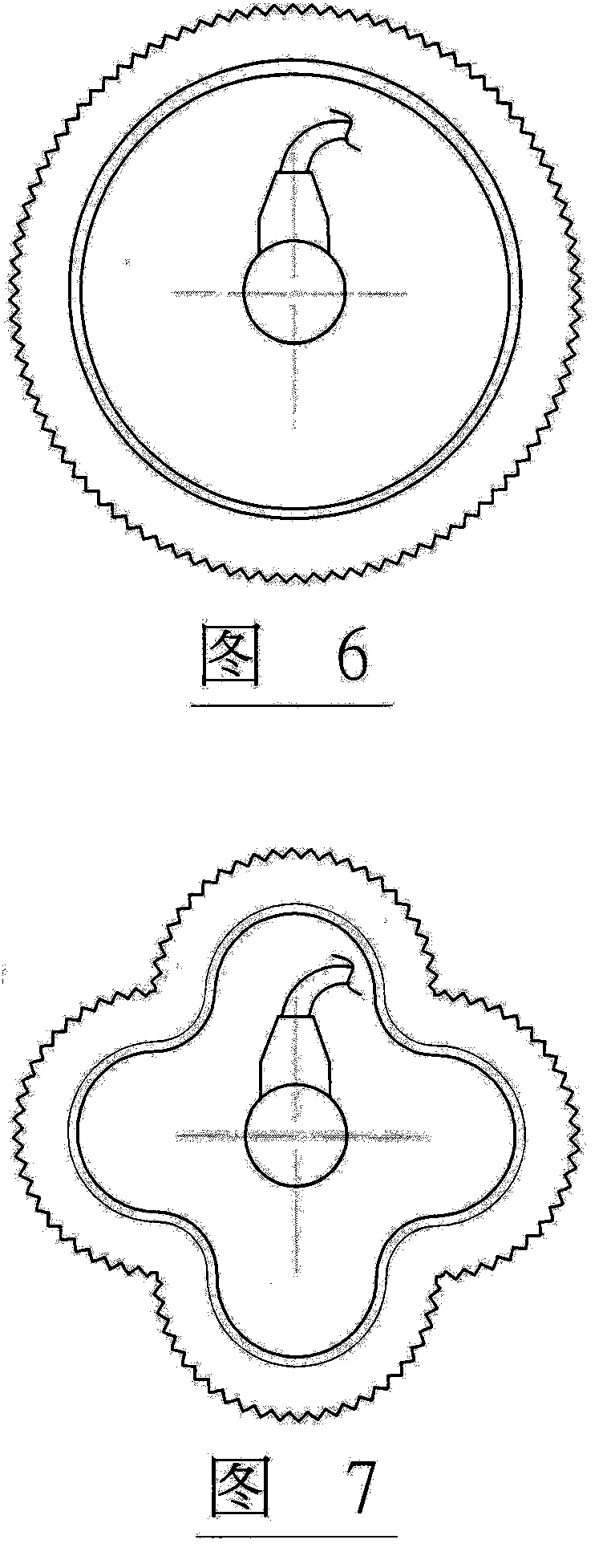

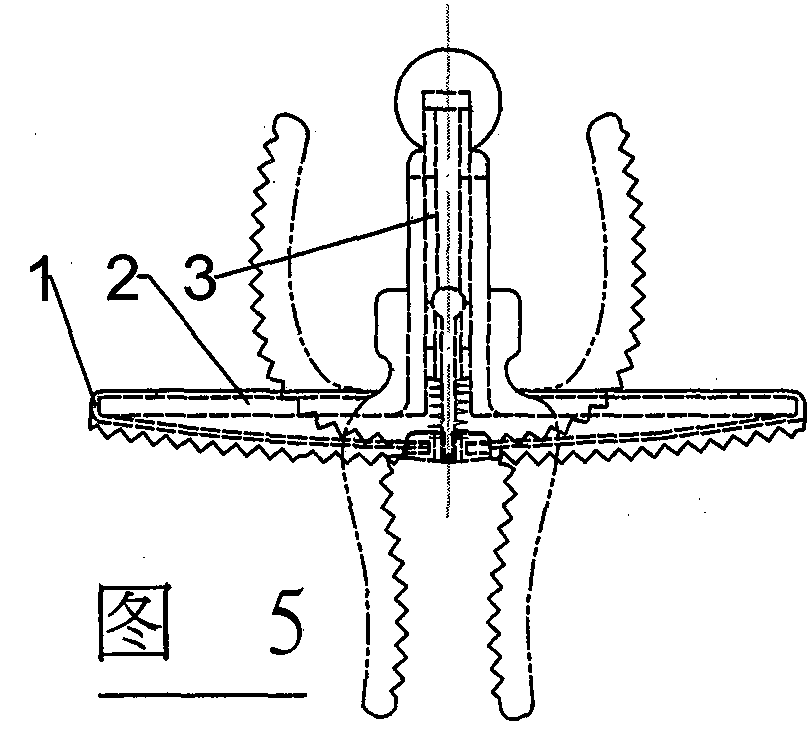

[0010] specific implementation plan

[0011] Below in conjunction with accompanying drawing, how the present invention is assembled and combined and concrete implementation are described: cleaning device is made of wiper, valve body, the switch control part structure in splash guard and valve body, and plastic components all adopt molding and molding process molding. The scrubbing cloth cover is formed by sewing the wiping cloth 1, the cloth cover 2, and the sponge pad 3; there is a splash cover handle 5 on the rubber splash guard 4 and the lower end of the valve body 6 in a sliding manner, which acts on the valve body. It is a key assembly structural part combining the valve handle 10 of the body opening switch and the scrubbing cloth cover; the seal ring lock nut 7 seals and fixes the rubber seal ring 8 and the valve stem 11 in the valve end lock nut 9, and then connects with the valve end lock nut 9. The upper part of the body 6 is connected to the internal thread interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com