Desulfurization wastewater zero discharge system and method convenient for cleaning

A desulfurization wastewater and zero-discharge technology, which is applied in chemical instruments and methods, water/sewage treatment, control/manipulation systems, etc., can solve the problems of reducing storage and buffering wastewater, affecting the evaporation effect of wastewater, and affecting normal opening and closing, etc., to achieve Reduce energy consumption and CO2 emissions, save water resources and clean energy consumption, and solve the effect of rising coal consumption for power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

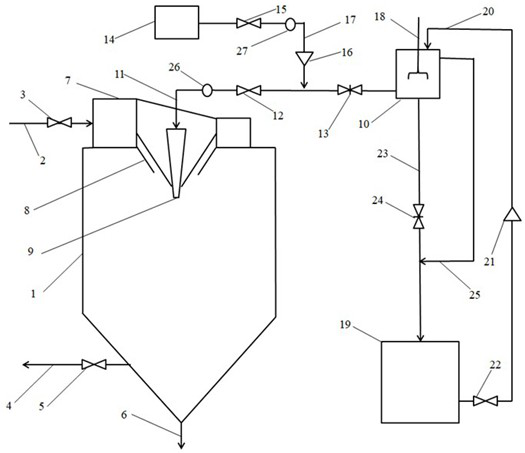

[0048] Such as figure 1 As shown, the zero-discharge system for desulfurization wastewater that is convenient for cleaning provided by this embodiment includes an evaporation tower 1, a flue gas conveying system, a waste water feeding system, a cleaning system and a control system (not shown), and the flue gas conveying system is used for Provide high-temperature flue gas to the evaporation tower 1, and the wastewater feeding system provides desulfurization wastewater to the evaporation tower 1 through the wastewater feeding pipeline. The wastewater feeding pipeline 11 is provided with a wastewater flow meter 26, a wastewater regulating valve 12 and a wastewater switching valve 13. The cleaning system communicates with the wastewater feeding pipeline 11 between the wastewater regulating valve 12 and the wastewater switching valve 13 through the cleaning water pipeline 17, and the cleaning water regulating valve 15 and the cleaning water booster pump 16 are arranged on the clean...

Embodiment 2

[0078] This embodiment provides a method for zero-discharge of desulfurization wastewater that is convenient for cleaning. The zero-discharge system for desulfurization wastewater in Example 1 is used. The method for zero-discharge of desulfurization wastewater includes: passing high-temperature flue gas and desulfurization wastewater through the flue gas delivery system and waste water respectively. The feeding system is sent to the evaporation tower 1, and the desulfurization wastewater is subjected to rotary atomization evaporation treatment with flue gas. During the treatment process, the wastewater flow meter 26 is used to monitor the wastewater flow and send the wastewater flow signal to the control system. The control system according to the wastewater flow signal Start the cleaning system and control the cleaning water regulating valve 15 and the cleaning water booster pump 16 to adjust the flow and pressure of the cleaning water.

[0079] to combine figure 1 , the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com