Rectangular tube inner wall dust removal device

A technology of cleaning device and rectangular tube, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

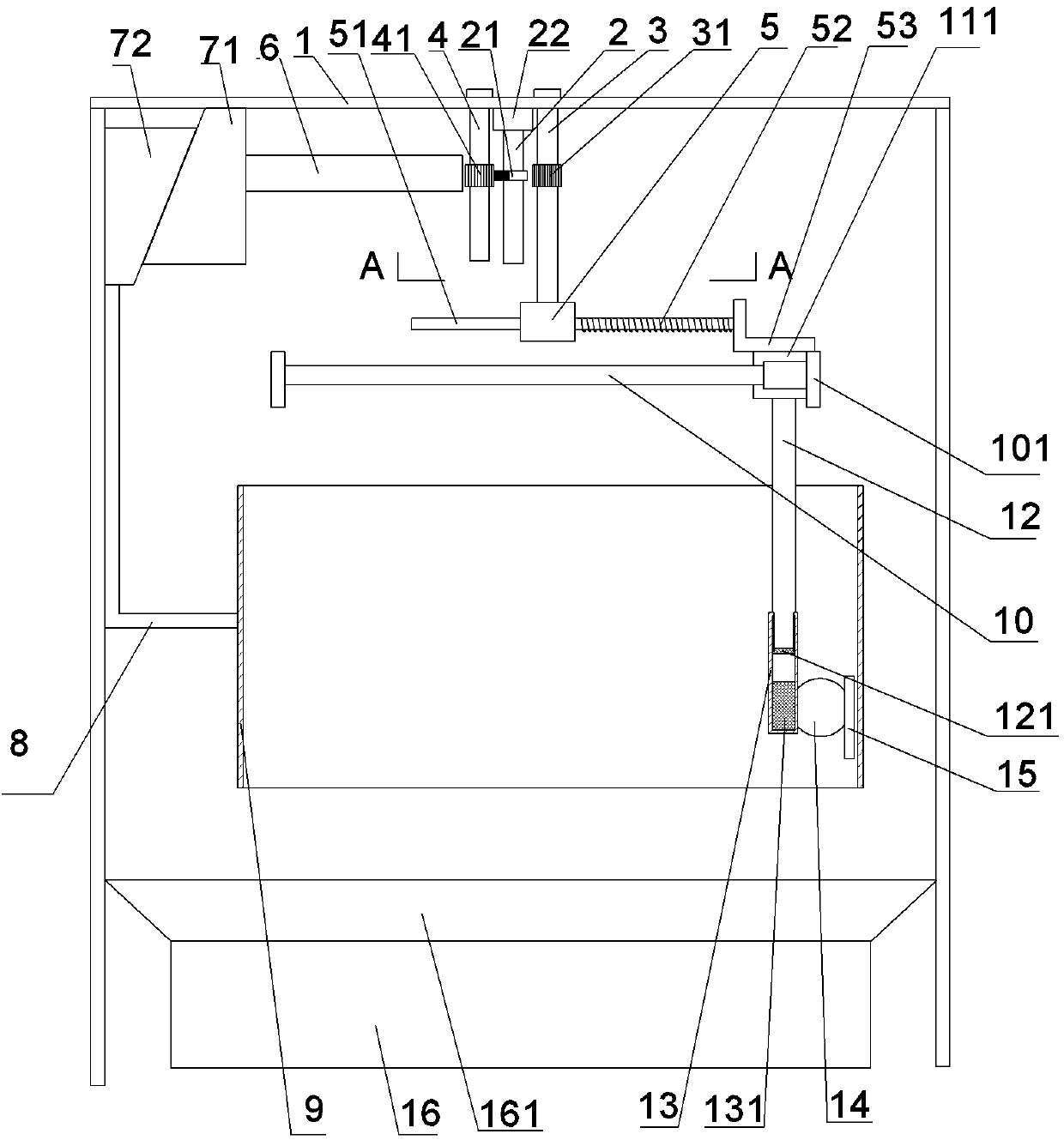

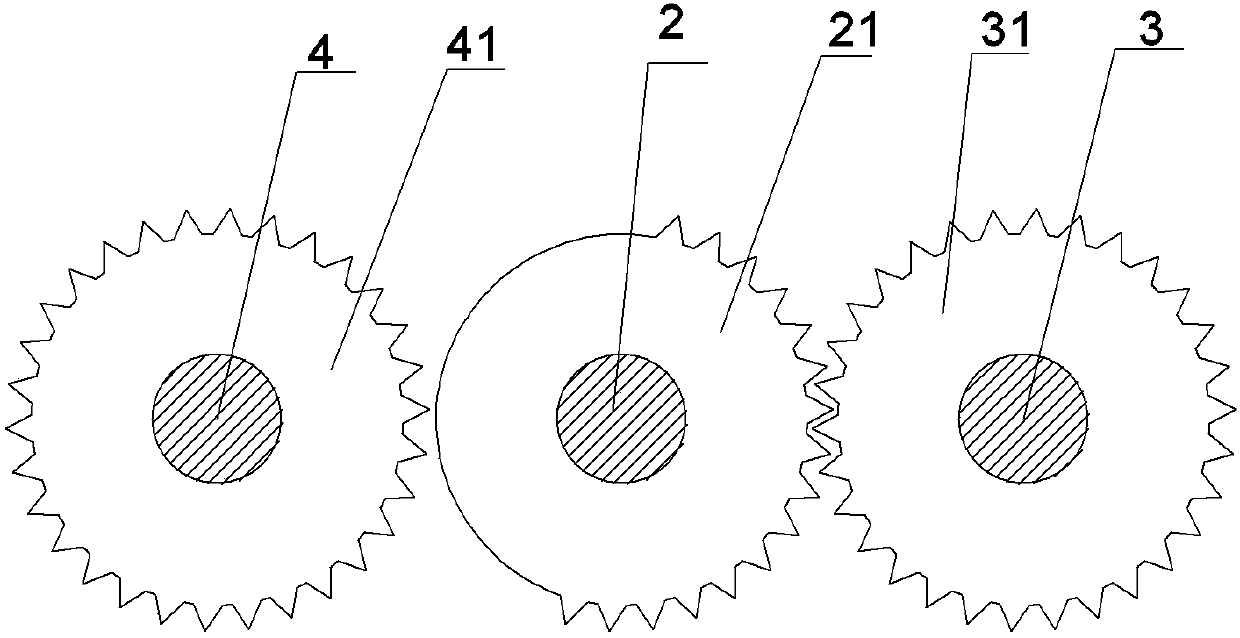

[0028] like figure 1 As shown, the cleaning device for the inner wall of a rectangular pipe fitting in this embodiment includes a frame 1, on which a driving shaft 2, a pipe fitting clamping mechanism and a cleaning mechanism are arranged, and the driving shaft 2 is vertically installed on the frame 1 through a bearing. Above, a motor 22 is also installed on the frame 1 to drive the drive shaft 2 to rotate. The drive shaft 2 is provided with an incomplete gear 21 through a flat key sleeve, and the central angle of the incomplete gear 21 is equal to one hundred and eighty degrees.

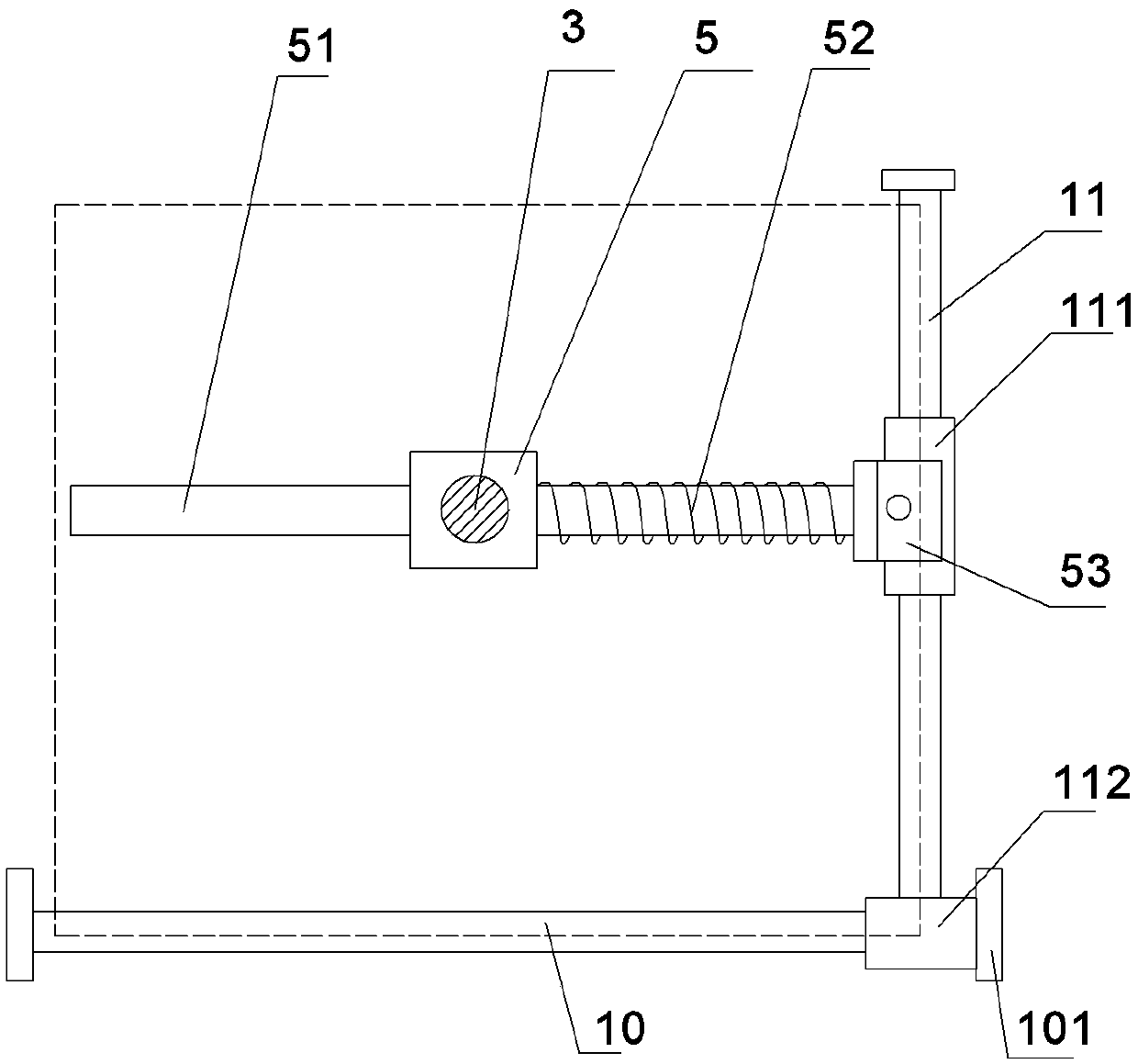

[0029] The cleaning mechanism comprises the first rotating shaft 3, fixed rod 10, slide rod 11, slide block 111 and rotating rod 51, as figure 1 and figure 2 As shown, the first rotating shaft 3 is parallel to the drive shaft 2, and the first rotating shaft 3 is provided with a first gear 31 capable of meshing with the incomplete gear 21 through a flat key sleeve, as figure 1 As shown, a connecti...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that the central angle of the incomplete gear 21 in this embodiment is 150 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com