Winding device used for multiple flexible pipelines

A winding device and multi-flexible technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve problems such as high cost, heavy weight of the carrying device, and unbalanced force on the working tool, and achieve cost reduction. Low, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

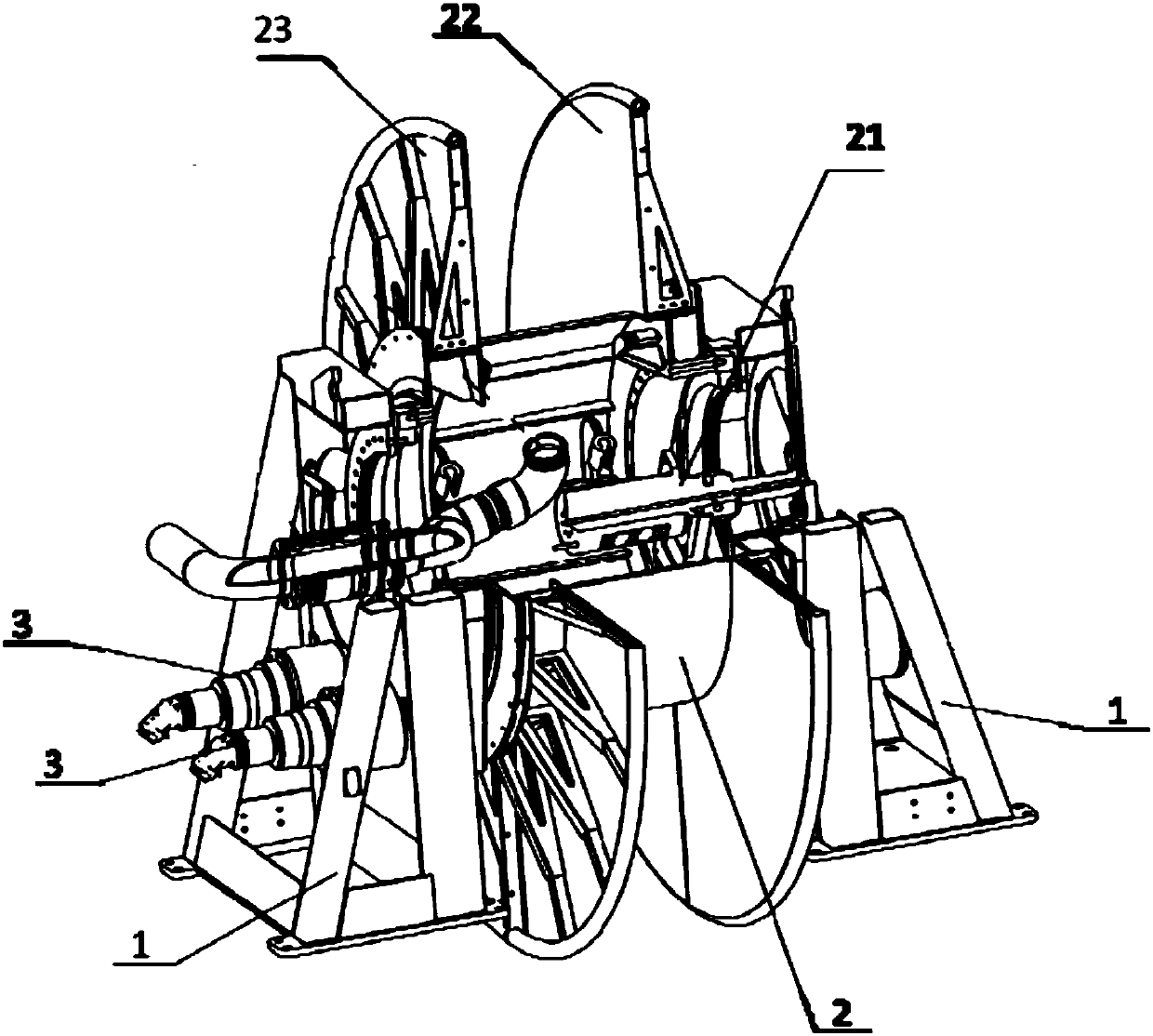

[0035] Such as figure 1 As shown, a winding device for multi-flexible pipelines, including a support 1, a rotating part 2 and several porous pipe clamps 4;

[0036] The rotating member 2 is arranged on the supporting member 1, and can rotate around the supporting member 1, and is used for winding the pipeline; in one implementation of this embodiment, the rotating member 2 can be realized by using a reel; figure 2 As shown, in the embodiment of the invention, the rotating member 2 is connected to the supporting member 1 (a support frame can be selected) in a manner supported at both ends, and the driving device 3 (a motor, etc., which can be The device for driving) drives to rotate around the rotation axis 21 of the rotating member 2;

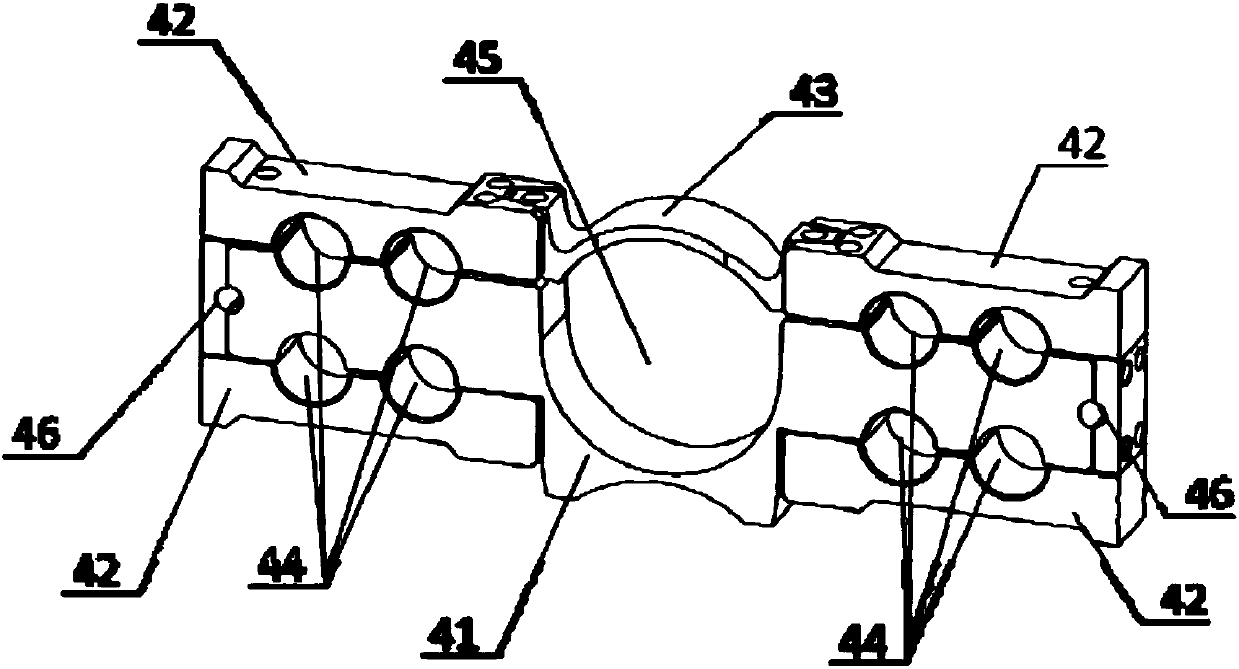

[0037] The porous pipe clamp 4 includes a connection support body 41 and several cover plates; the connection support body 41 is provided with several grooves of different sizes; the number of the grooves is the same or different from the num...

Embodiment 2

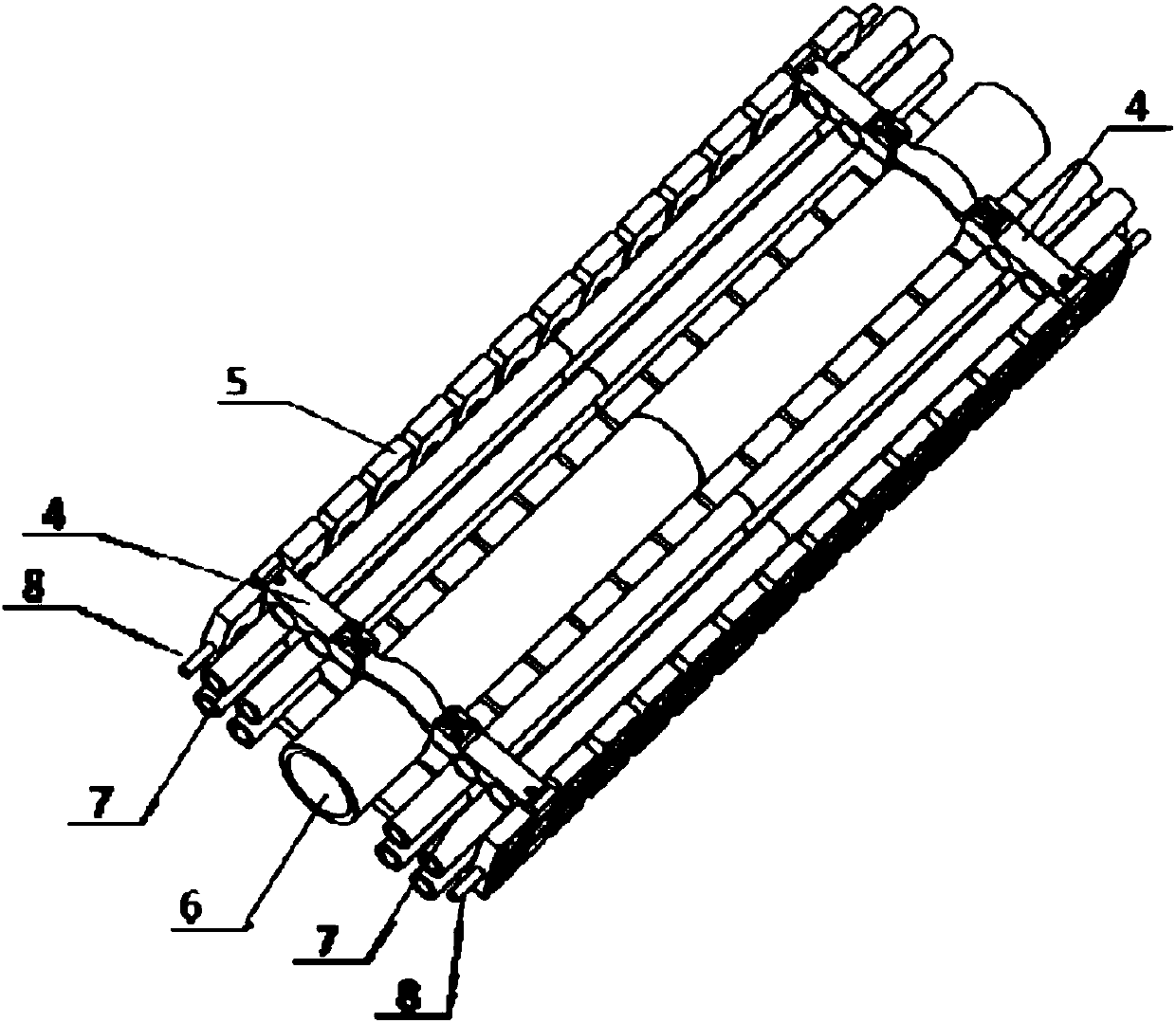

[0042] Based on embodiment 1, in the embodiment of the present invention, such as Figure 3-5As shown, in order to prevent the upper and lower layers of pipelines in the rotary member 2 from being squeezed against each other, the winding device for multi-flexible pipelines also includes several spacers 5; the spacers 5 are arranged between two adjacent porous pipe clamps 4, it is connected with the corresponding porous pipe clamp 4 through a guide 8 (preferably a guide rope), and is neatly arranged between each porous pipe clamp 4 without rotation deflection; during specific implementation, the spacer block 5 and the corresponding positions on the two ends 51 of the porous pipe clamp 4 are all provided with through holes (see figure 2 46 in and Figure 5 54) is used for the passage of the guide member 8, and at least two guide ropes are provided between the spacer block 5 and the porous pipe clamp 4; during actual work: the guide rope passes through the porous pipe clamp 4 a...

Embodiment 3

[0047] Based on Embodiment 1 or Embodiment 2, in the embodiment of the present invention, the rotating member 2 is a reel, and the two sides of the rotating member 2 in the axial direction are respectively provided with a first baffle 22 and a second baffle 23 (The first baffle plate 22 and the second baffle plate 23 can be installed on the rotating member 2 by bolts), the first baffle plate 22 and the second baffle plate are parallel to each other, and the extension direction of the two is in line with the rotation direction. The extension direction of the piece 2 is vertical, and the rotating arrow can be rotated forward and backward to retract the hose line (not shown in the figure). The first baffle plate 22 and the second baffle plate 23 are used to limit the pipeline wound on the rotating piece 2 from outward shift.

[0048] In summary:

[0049] The invention provides a winding device for multi-flexible pipelines, which can place multiple hoses of different sizes (such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com