Deep repairing method for turboprop airplane propeller hub sealing face

A sealing surface and propeller technology, applied in the aerospace field, can solve the problems of long repair cycle, high cost, inconvenience to domestic customers, etc., and achieve the effect of reducing maintenance cost, easy operation, and restoring mechanical properties and material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

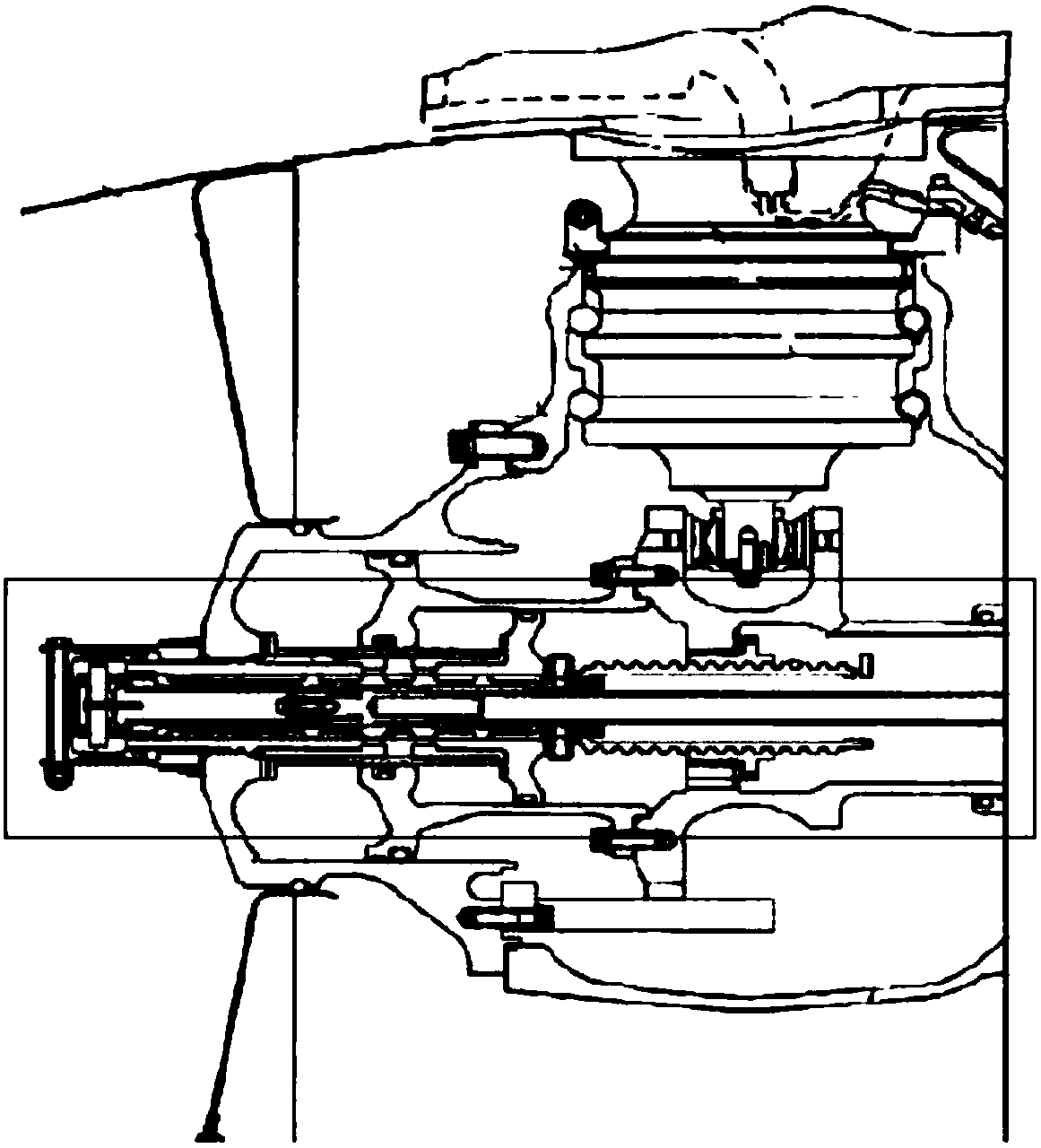

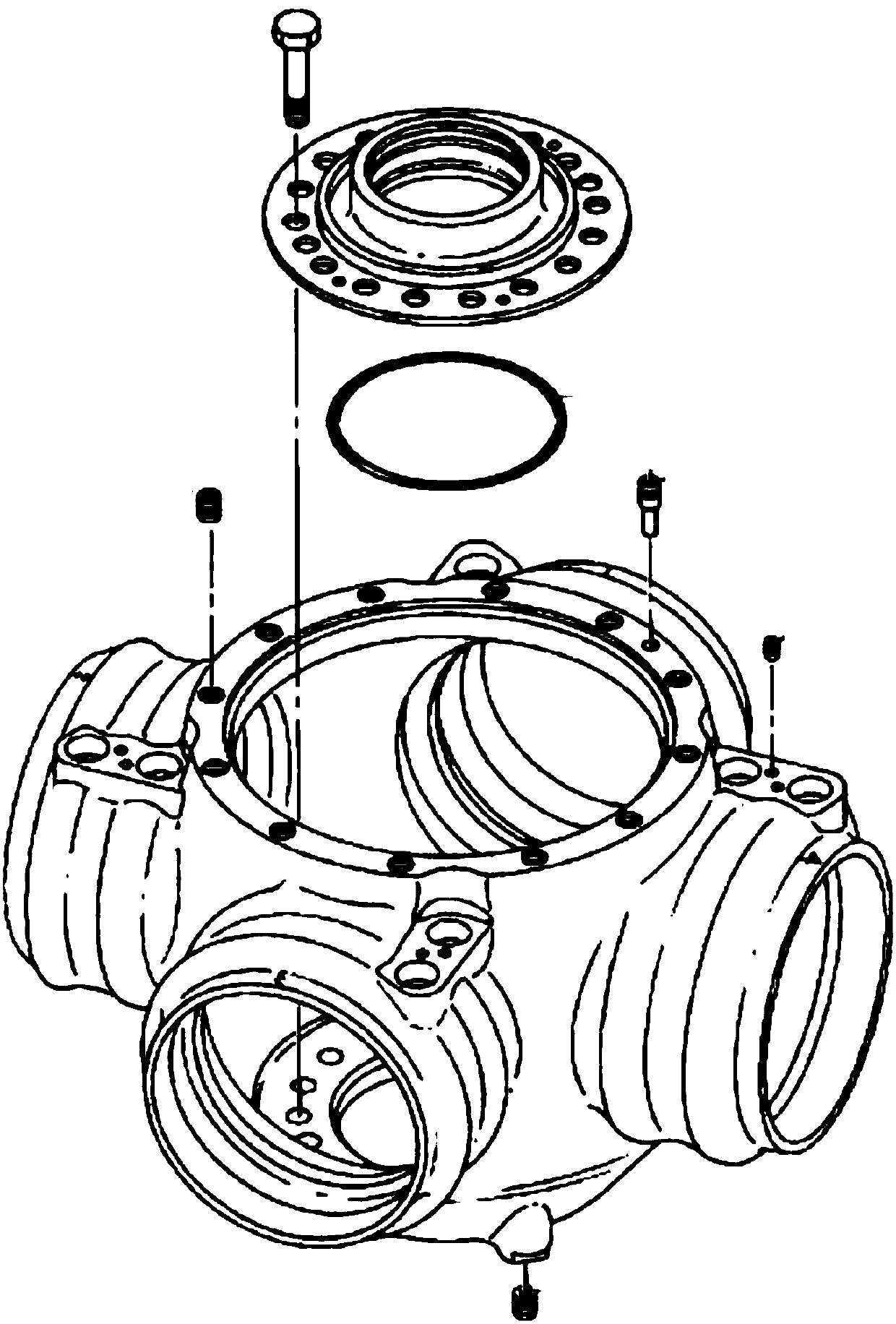

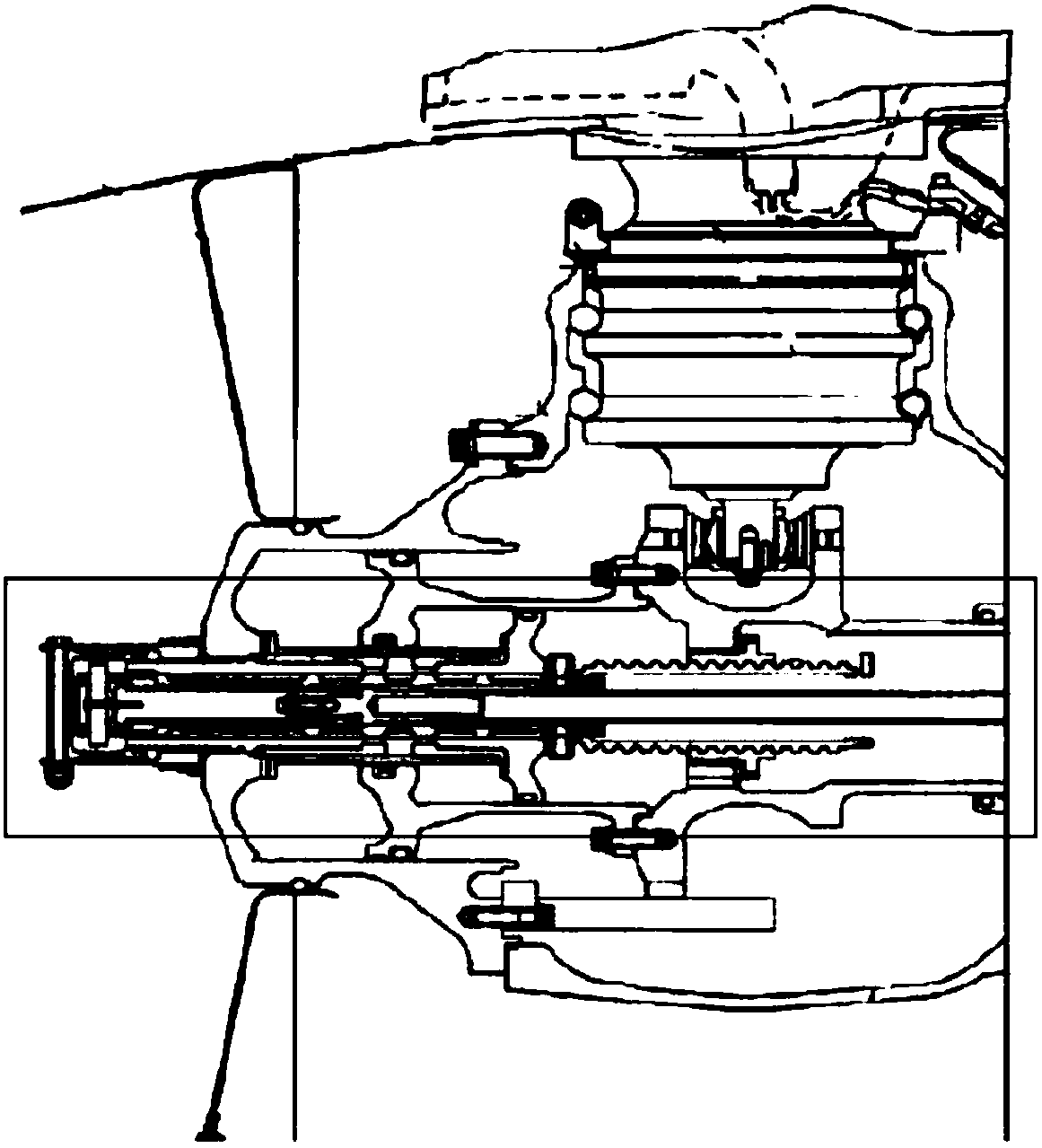

[0021] Referring to the accompanying drawings, it can be seen that the method for repairing the depth of the sealing surface of the turboprop propeller hub is characterized in that it comprises the following process steps:

[0022] Step 1: According to the standard of American Society for Testing and Materials (ASTM E1444), conduct magnetic particle inspection on the damaged area of the propeller hub sealing surface;

[0023] Step 2: According to the standard (BAC) of Boeing Company of the United States, thermal damage inspection is carried out on the damaged area of the hub sealing surface of the propeller, and the thermal damage readi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com