Control method and system for preventing damage of compressor

A control method and compressor technology, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as burning, compressor damage, and compressor failure to stop working, so as to avoid damage or burning and improve fault tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

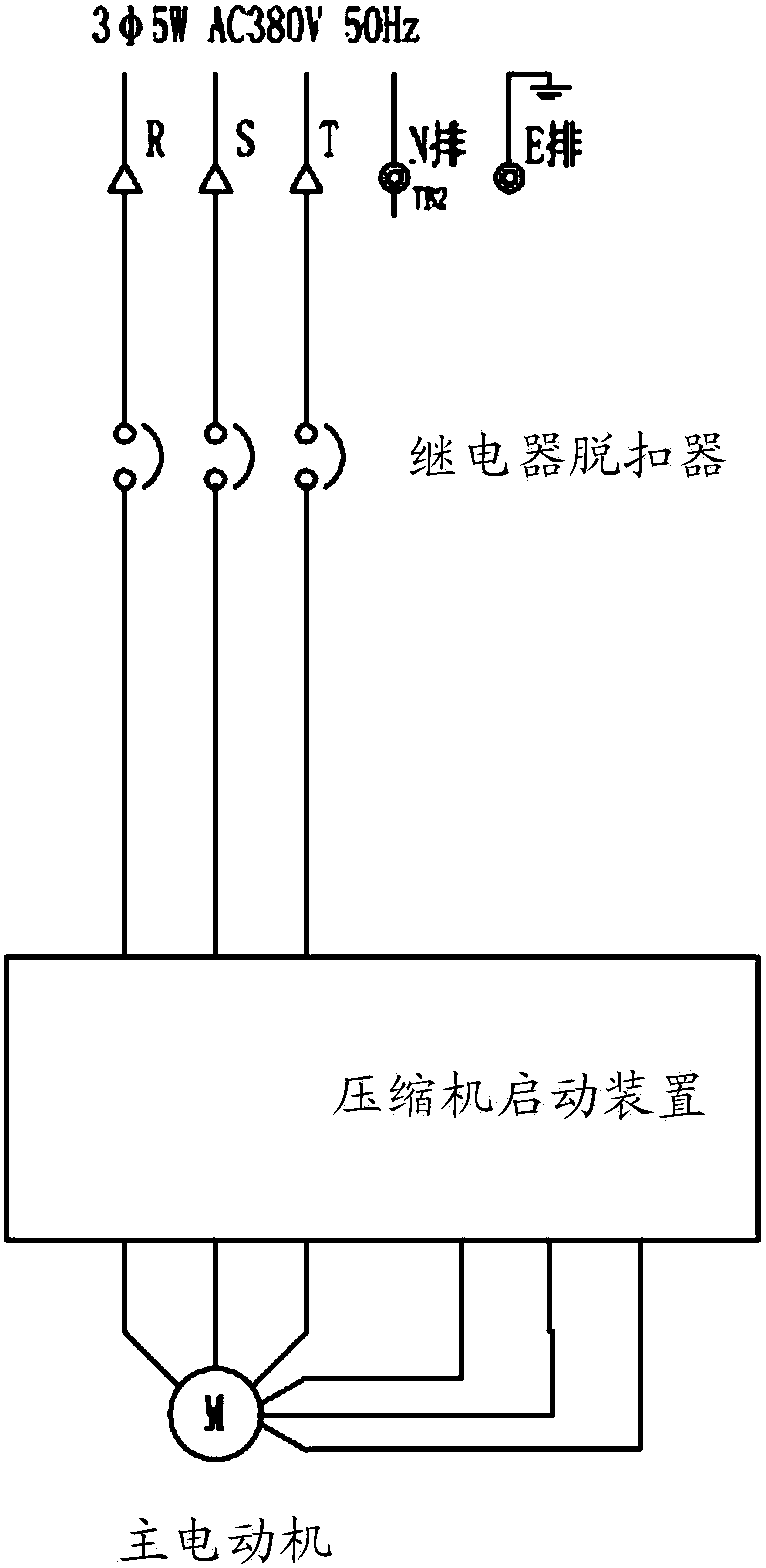

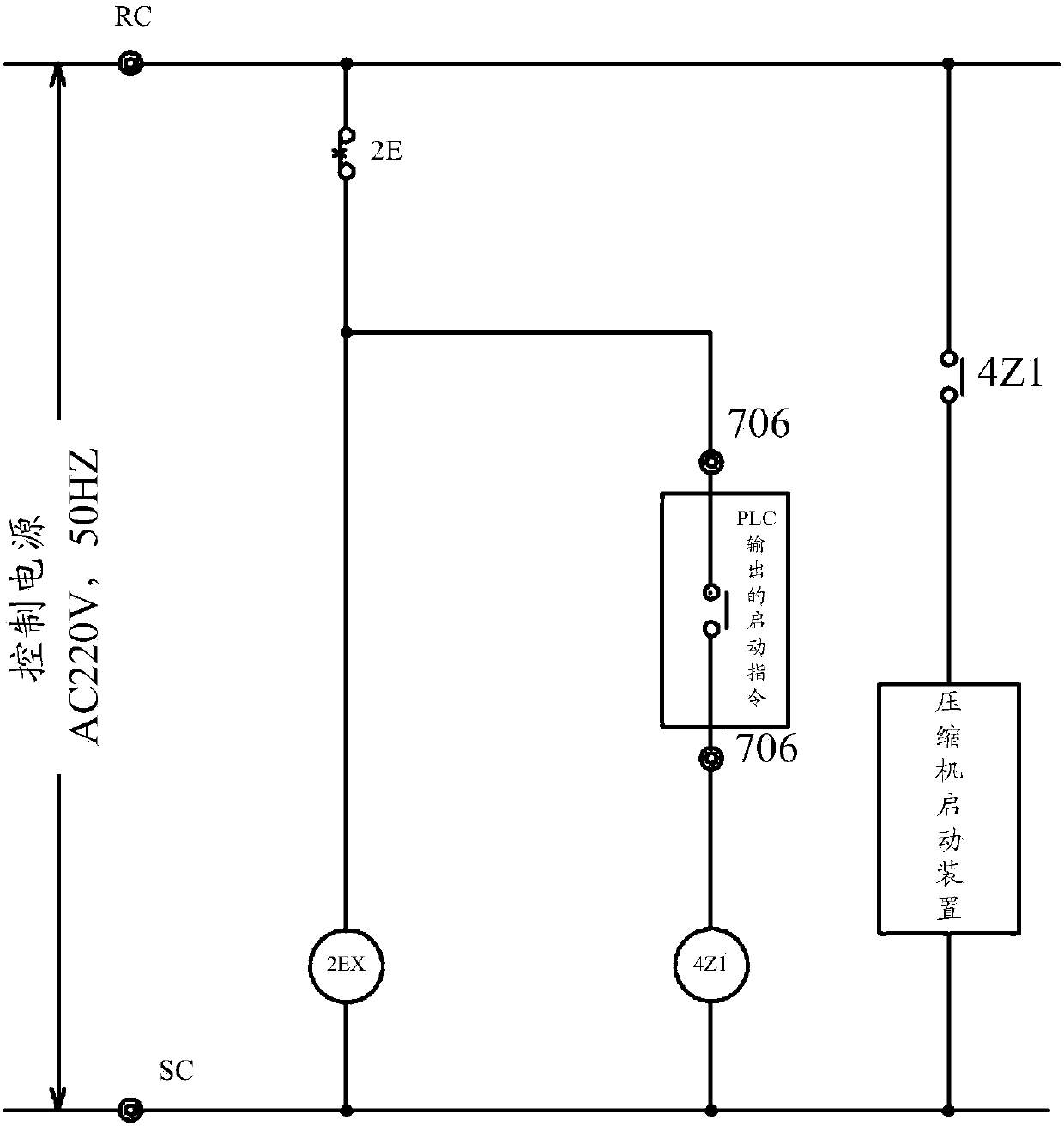

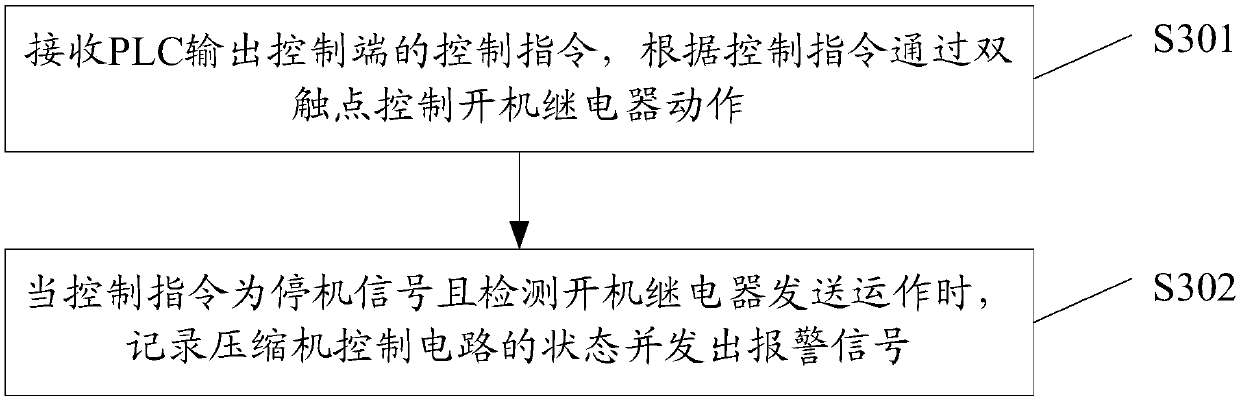

[0048] Please refer to the attached image 3 , image 3 It is a schematic flowchart of a control method for preventing compressor damage provided by Embodiment 1 of the present invention. Such as image 3 As shown, the embodiment of the present invention discloses a control method for preventing compressor damage, which is applied to the compressor control circuit, the compressor control circuit controls the compressor starting device, and the digital switch of the compressor control circuit adopts double contacts, increasing The second contact of the second contact is connected in series with the contact of the start-up relay, and is connected in series with the contact of the start-up relay to control the emergency stop contact of the compressor control circuit for emergency stop. The control method includes:

[0049] S301. Receive a control command from the PLC output control terminal, and control the action of the start-up relay through the double contacts according to t...

Embodiment 2

[0054] Please refer to the attached Figure 4 , Figure 4 It is a schematic flowchart of a control method for preventing compressor damage provided by Embodiment 2 of the present invention. Such as Figure 4 As shown, the embodiment of the present invention discloses a control method for preventing compressor damage, which is applied to the compressor control circuit, the compressor control circuit controls the compressor starting device, and the digital switch of the compressor control circuit adopts double contacts, increasing The second contact of the switch is connected in series with the contacts of the start-up relay and the circuit breaker release is connected in series with the PLC output control terminal and the power supply terminal, which is connected in series with the contacts of the start-up relay to control the emergency stop contacts of the compressor control circuit for emergency stop. The compressor control circuit also includes: a circuit breaker release c...

Embodiment 3

[0063] Please refer to the attached Figure 5 , Figure 5 It is a schematic flowchart of a control method for preventing compressor damage provided by Embodiment 3 of the present invention. Such as Figure 5 As shown, the embodiment of the present invention discloses a control method for preventing damage to the compressor, which is applied to the compressor control circuit. The compressor control circuit controls the compressor starting device. The second contact of the second contact is connected in series with the contact of the start-up relay, is connected in series with the contact of the start-up relay, controls the emergency stop contact of the emergency stop of the compressor control circuit, and the compressor control circuit also includes: connected in series with the PLC output control terminal and A circuit breaker trip unit between the power terminals, the control method includes:

[0064] S501. Receive a control command from the PLC output control terminal, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com