High-efficiency hot-air fixating machine

A hot air degreening machine, high-efficiency technology, applied in the direction of tea treatment before extraction, etc., can solve the problems that the heating effect is not as good as steam heating, the adverse effect on tea quality, and the incomplete bud tip decapitation, so as to achieve less energy consumption and reduce labor intensity of workers , the effect of keeping the discharge of water droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

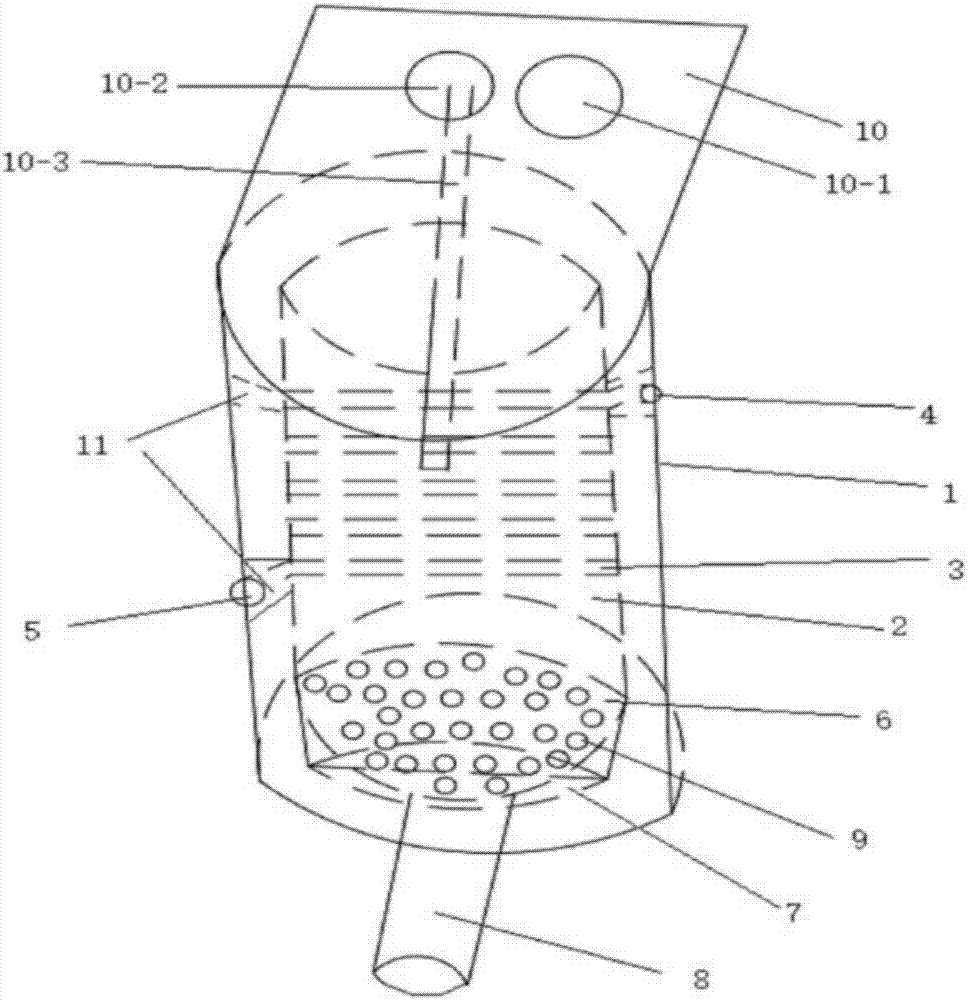

[0027] Such as figure 1 The high-efficiency hot air cleaning machine includes a cylinder body 2, a casing 1, a coil pipe 3, an air inlet 4, an air outlet 5, a water outlet chassis 6, a turntable 7, a water diversion pipe 8, a water outlet hole 9, a cut-off layer 11, The cylinder cover 10, the coil 3 is installed on the surface of the cylinder 2, the air inlet 4 is located on the upper part of the cylinder 2, the steam enters from the air inlet, flows through the coil 3, and flows from the lower part of the cylinder 2. The air outlet 5 is discharged, the water outlet chassis 6 is located at the bottom of the cylinder body 2, and a plurality of water outlet holes 9 are distributed on the surface, and a water outlet chassis is connected above the turntable. When the turntable rotates, it drives the cylinder to rotate, and the water diversion pipe It is connected under the turntable to discharge the water flowing out of the book publishing chassis. When the cut-off layer introduce...

Embodiment 2

[0038] Such as figure 1 The high-efficiency hot air cleaning machine includes a cylinder body 2, a casing 1, a coil pipe 3, an air inlet 4, an air outlet 5, a water outlet chassis 6, a turntable 7, a water diversion pipe 8, a water outlet hole 9, a cut-off layer 11, The cylinder cover 10, the coil 3 is installed on the surface of the cylinder 2, the air inlet 4 is located on the upper part of the cylinder 2, the steam enters from the air inlet, flows through the coil 3, and flows from the lower part of the cylinder 2. The air outlet 5 is discharged, the water outlet chassis 6 is located at the bottom of the cylinder body 2, and a plurality of water outlet holes 9 are distributed on the surface, and a water outlet chassis is connected above the turntable. When the turntable rotates, it drives the cylinder to rotate, and the water diversion pipe It is connected under the turntable to discharge the water flowing out of the book publishing chassis. When the cut-off layer introduce...

Embodiment 3

[0049] Such as figure 1 The high-efficiency hot air cleaning machine includes a cylinder body 2, a casing 1, a coil pipe 3, an air inlet 4, an air outlet 5, a water outlet chassis 6, a turntable 7, a water diversion pipe 8, a water outlet hole 9, a cut-off layer 11, The cylinder cover 10, the coil 3 is installed on the surface of the cylinder 2, the air inlet 4 is located on the upper part of the cylinder 2, the steam enters from the air inlet, flows through the coil 3, and flows from the lower part of the cylinder 2. The air outlet 5 is discharged, the water outlet chassis 6 is located at the bottom of the cylinder body 2, and a plurality of water outlet holes 9 are distributed on the surface, and a water outlet chassis is connected above the turntable. When the turntable rotates, it drives the cylinder to rotate, and the water diversion pipe It is connected under the turntable to discharge the water flowing out of the book publishing chassis. When the cut-off layer introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com