A method for controlling cracks in the web center of profiled billets

A control method and center crack technology, which is applied in the field of web center crack control of special-shaped slabs, can solve problems such as web center cracks, complex casting sections, and special forms of casting slab support systems in the secondary cooling zone of the mold, so as to enhance competitiveness , Improve the internal quality and rolling yield, and eliminate the effect of the occurrence rate of crack defects in the center of the web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Utilize the determination method of the wingtip taper of the special-shaped mold crystallizer that the method involved in the present invention formulates to obtain application on the spot,

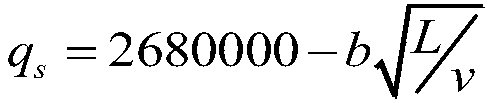

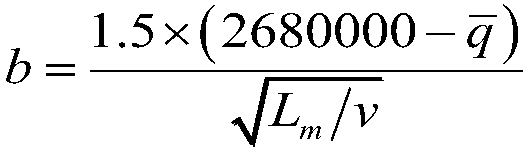

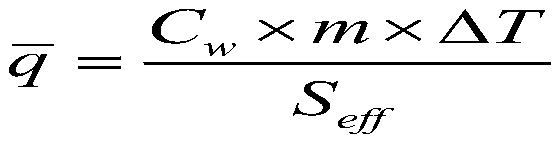

[0037] A method for controlling cracks in the web center of a special-shaped billet, the specific steps and parameters are as follows:

[0038] 1. Obtain the distance between the outlet of the billet support system of the special-shaped billet continuous caster and the mold meniscus:

[0039] The section size of the profile billet continuous casting machine is 295mm×205mm×85mm; the arc radius of the caster foundation is 10m; The first cooling zone and the second cooling zone The second cooling zone is composed of three cooling circuits, the inner arc, the outer arc and the side of the slab, and there are 7 cooling circuits in total. The distance between the exit of the slab supporting system and the meniscus of the mold is 4.9m, including the length of the foot roll area of 0.77...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com