Pearl powder celadon mass production device

A technology for mass production and pearl powder, which is applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of inconvenient perlite raw material water injection, inconvenient adjustment of water injection amount, and unfavorable perlite raw material mixing work. , to achieve the effect of simple structure, high practical performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

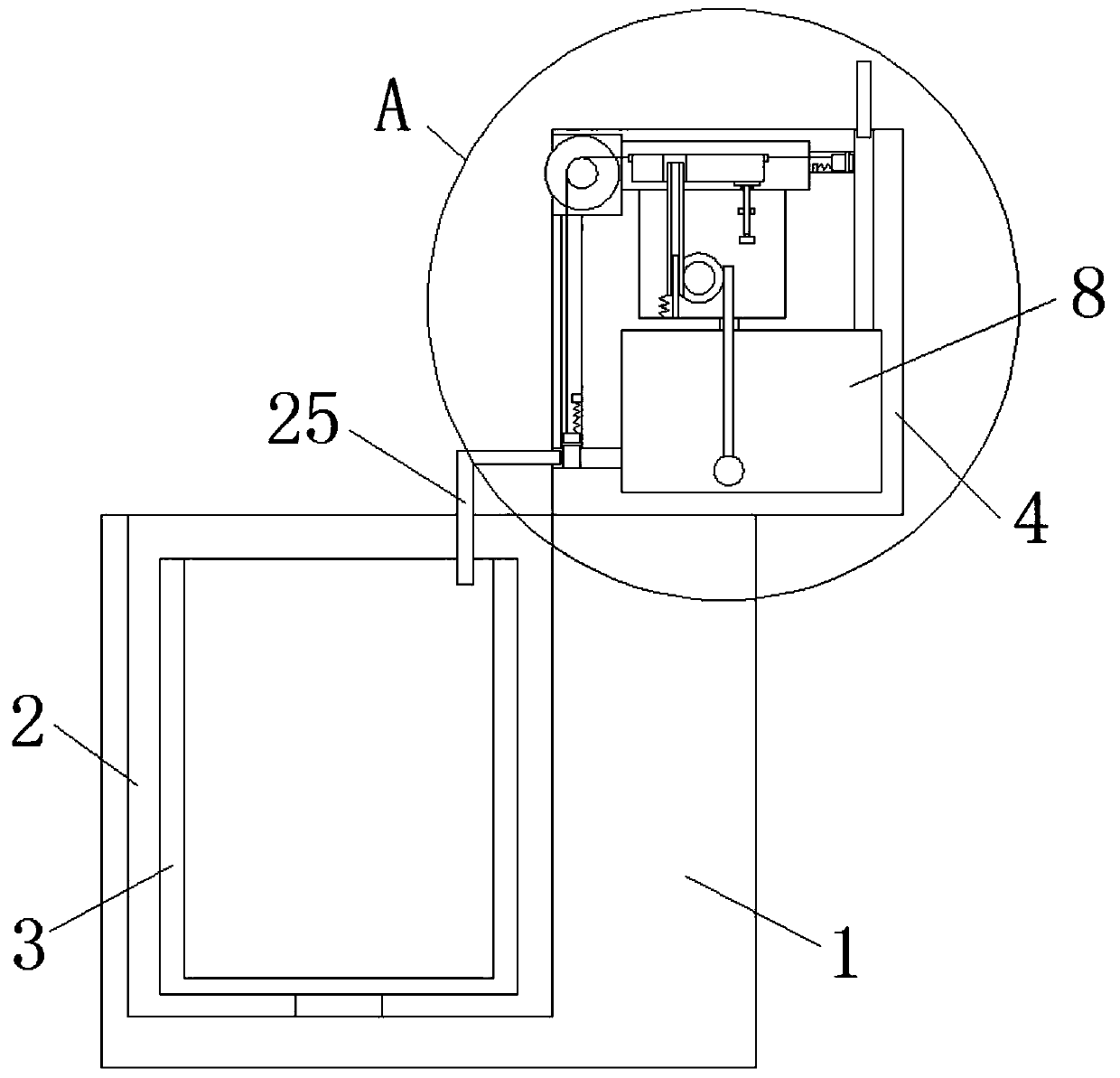

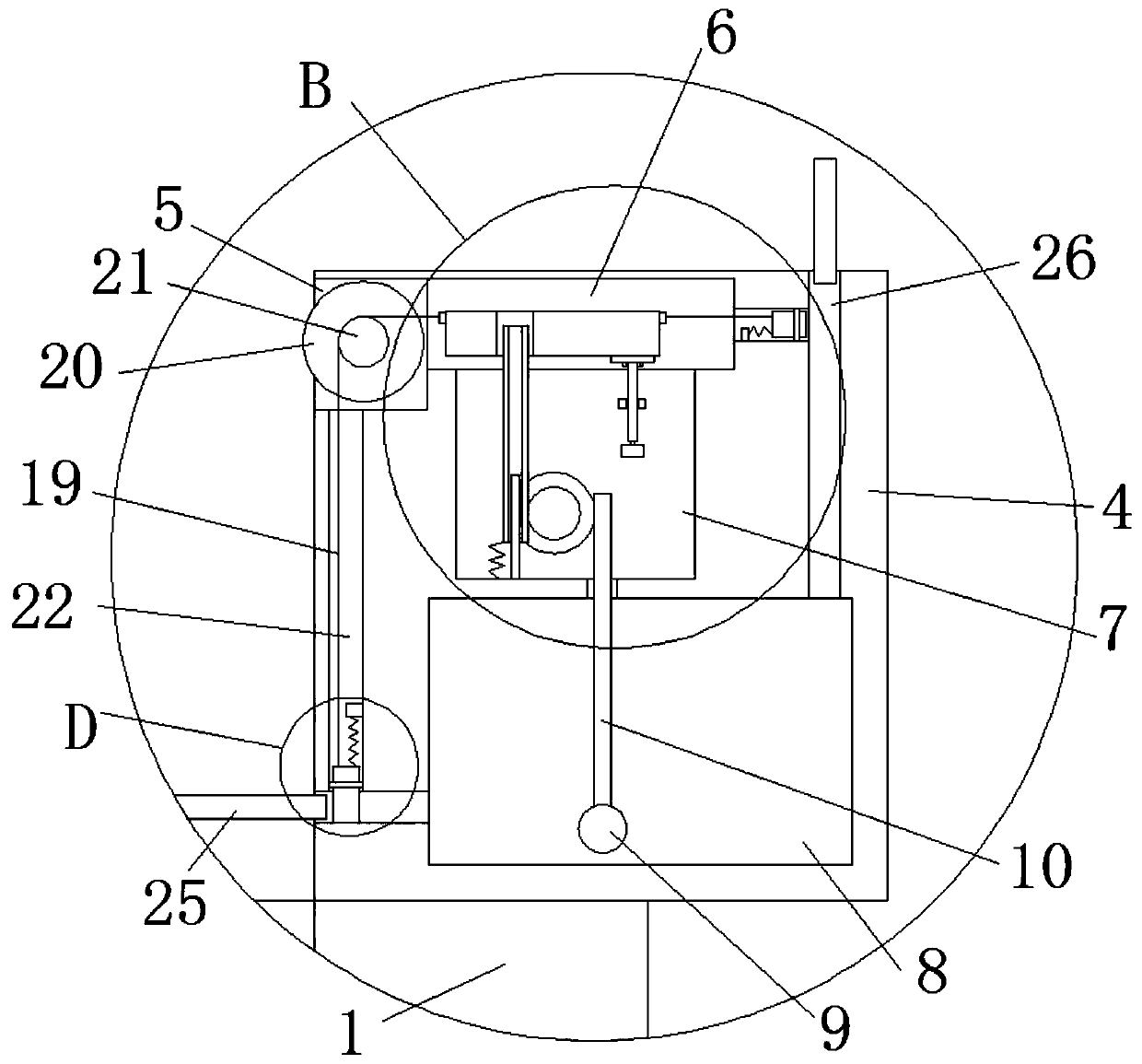

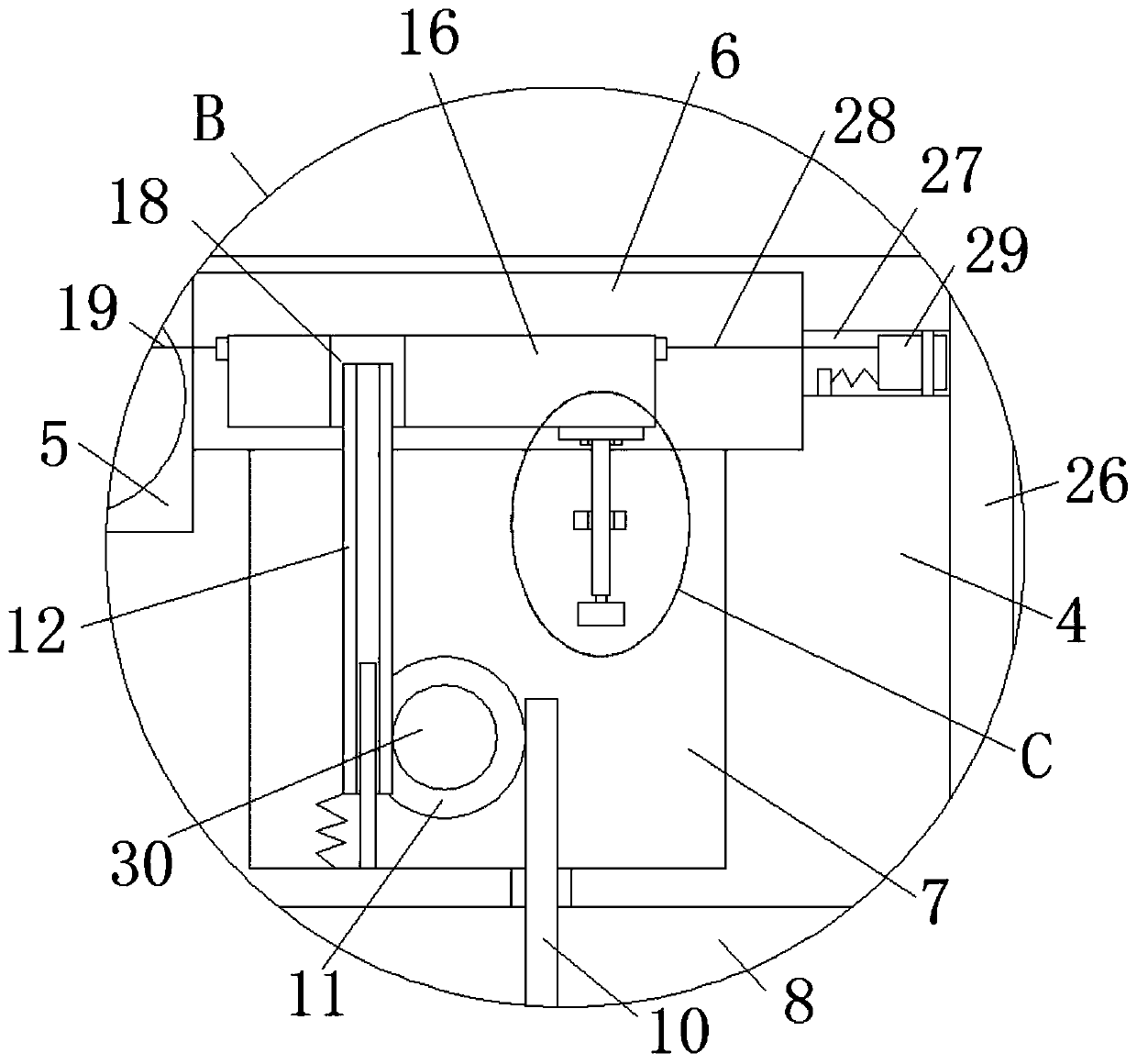

[0024] refer to Figure 1-5 , the pearl powder celadon mass production device is proposed in the present embodiment, comprising a stirring table 1, the top of the stirring table 1 is provided with a stirring tank 2, a stirring drum 3 is installed for rotation in the stirring tank 2, and a stirring tank 3 is installed on one side of the top of the stirring table 1 Water injection platform 4, one side of water injection platform 4 is provided with regulating groove 5, and the side inner wall of regulating groove 5 is provided with first groove 6, and the bottom inner wall of first groove 6 is provided with second groove 7, the second The bottom of the second groove 7 is provided with a water storage chamber 8 provided on the water injection table 4, and a floating ball 9 is arranged in the water storage chamber 8, and a light rod 10 is installed on the top of the floating ball 9, and the top of the light rod 10 Extending into the second groove 7, one side of the lightweight rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com