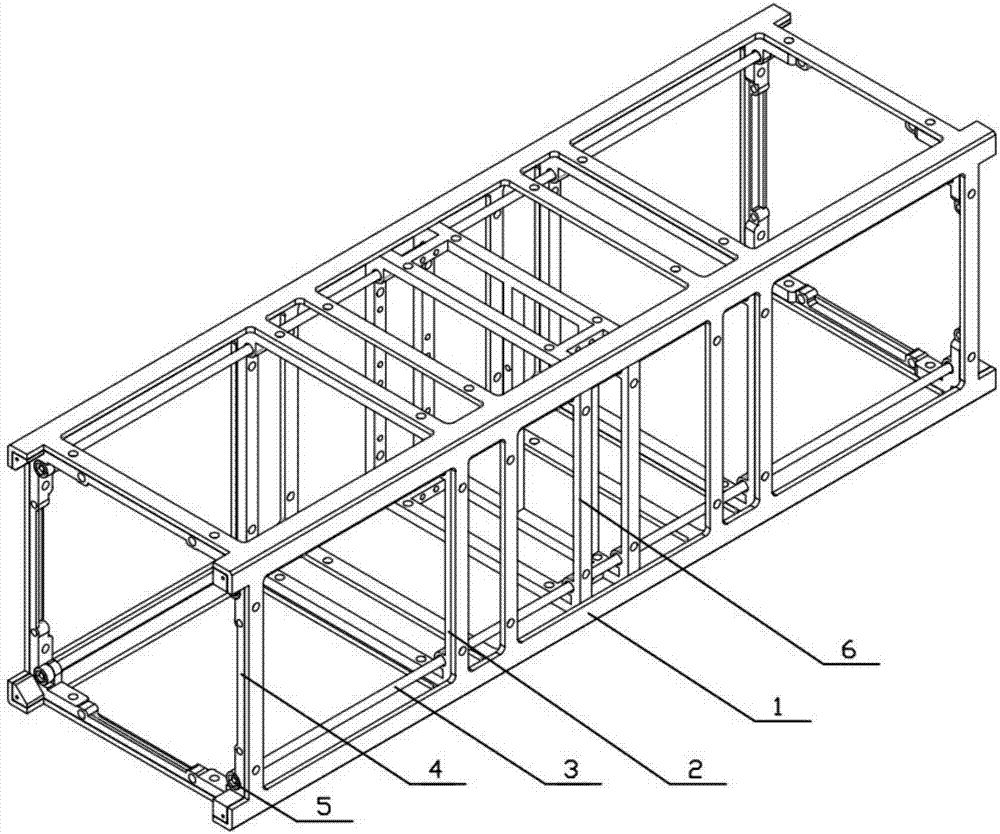

Three-unit cube satellite main load bearing structure

A three-unit, cubic technology, applied in the direction of artificial satellites, space navigation equipment, space navigation equipment, etc., can solve the problems that the cube star cannot be pushed into space, the parallelism cannot be guaranteed, and the work is meaningless, etc., to achieve Reducing mass and space constraints, good structural integrity, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

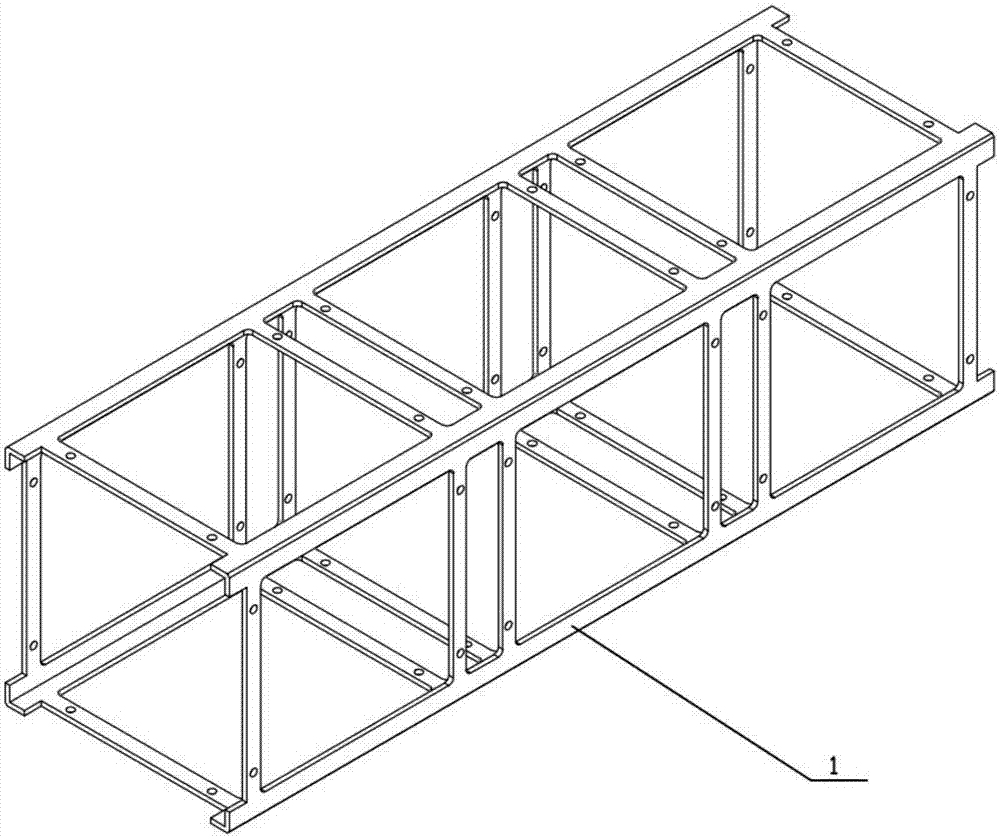

[0031] combine Figure 1~Figure 6 , the present invention is a three-unit cubic star main load-bearing structure, including a main frame 1, a middle bracket 6, two middle square skeletons 2, four screw rods 3, two square end covers 4 and eight end nuts 5; The main frame 1 is a cuboid, including four columns and several connecting rods. The four columns form a square with a section of 100mm×100mm. The connecting rods are used to connect two adjacent columns to improve its overall rigidity; the four columns of the main frame 1 The first column and several connecting rods are integrally formed parts of Al7075 material, which are processed from a whole piece of aluminum alloy. A heat-controlling multi-layer material is arranged at the rectangular hollow formed by the four uprights of the main frame 1 and several connecting rods to play the role of thermal insulation.

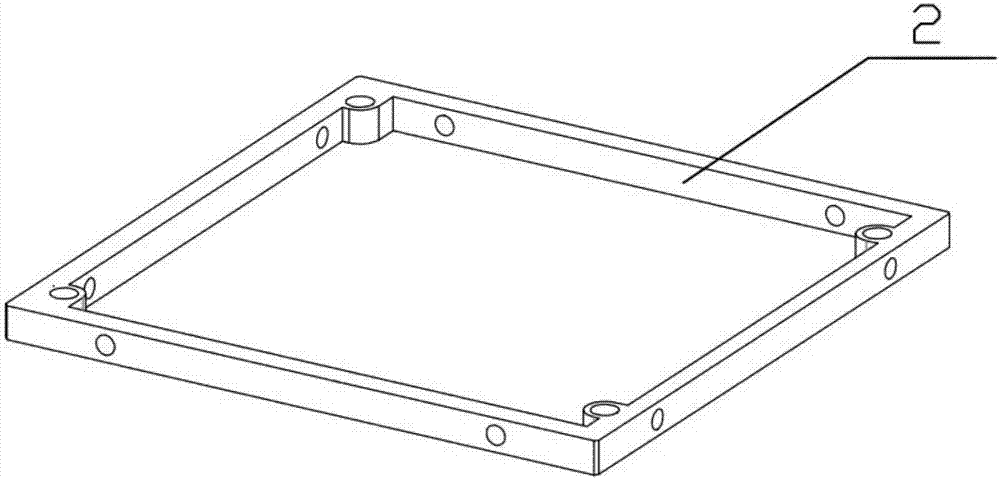

[0032]The two middle square skeletons 2 are arranged in the main frame 1 in parallel and at intervals, and their...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com