Preparation and Application of a Composite Optical Switching Nanoparticle Tuneable to Stable White Light

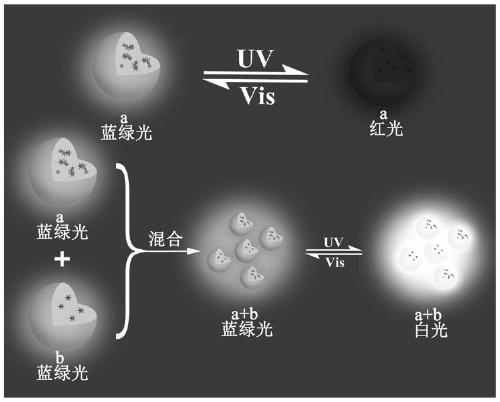

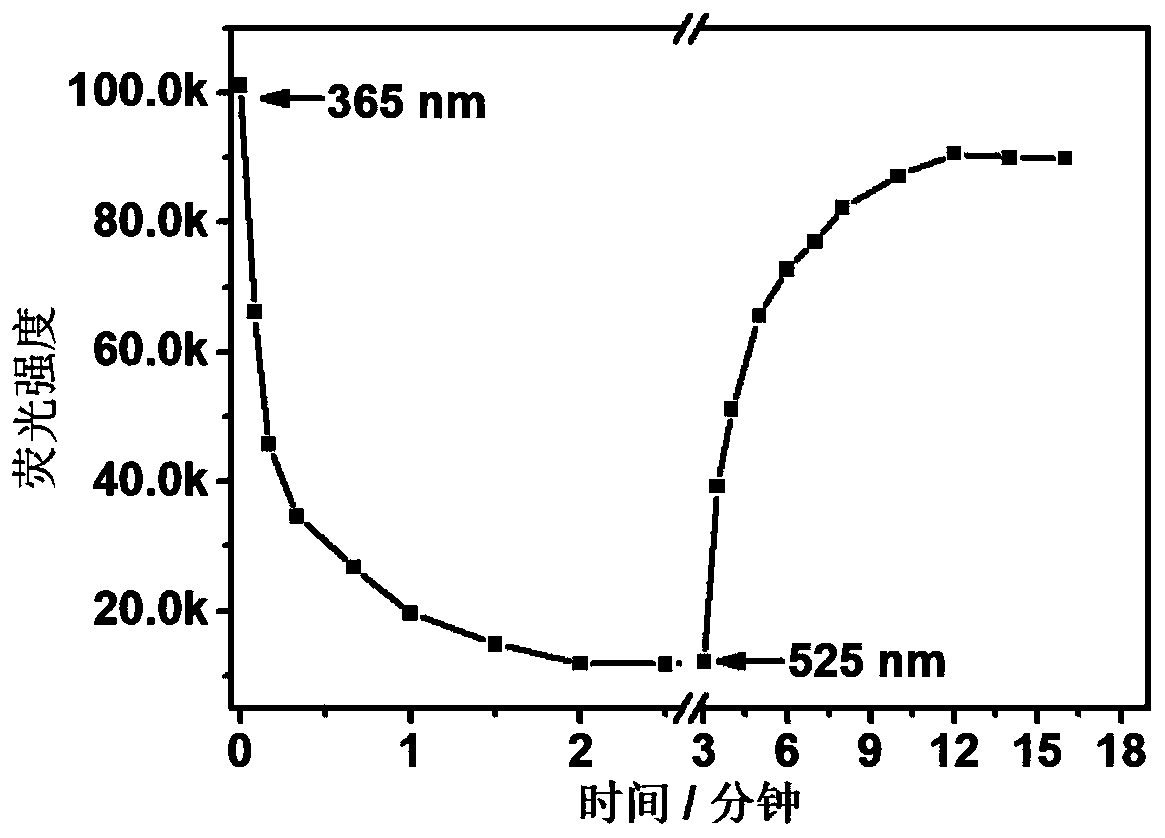

A nanoparticle and composite light technology, applied in the field of composite optical switch nanoparticle and chemical material preparation, can solve the problems of inability to control white light, unable to obtain white light, low yield, etc., and achieve the effect of simple synthesis and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation of composite optical switch nanoparticles adjustable to stable white light, the specific steps are as follows:

[0052] (1) 0.40g of styrene, 0.10g of divinylbenzene, 0.006g of p-DTPACO, 0.020g of ethyl-3,3-dimethyl-6-nitroindoline spiropyranyl methacrylate, Mix and stir 0.075g of n-hexadecane and 0.025g of azobisisobutyronitrile evenly, then disperse in 10mL of CTAC aqueous solution with a concentration of 0.01g / mL, ultrasonic emulsify until a stable and uniform fine emulsion is formed, and react at 75°C for 3 hours Finally, the optical switch nanoparticle a is obtained.

[0053] (2) Mix and stir 0.40g of styrene, 0.10g of divinylbenzene, 0.006g of p-DTPACO, 0.075g of n-hexadecane, and 0.025g of azobisisobutyronitrile, and then disperse them in the concentration of 0.01g / mL Ultrasonic emulsification in 10 mL of CTAC aqueous solution to form a stable and uniform miniemulsion, and react at 75° C. for 3 hours to obtain nanoparticles b.

[0054] (3) Composi...

Embodiment 2

[0056] A preparation of composite optical switch nanoparticles adjustable to stable white light, the specific steps are as follows:

[0057] (1) 0.40g of styrene, 0.10g of divinylbenzene, 0.004g of p-DTPACO, 0.020g of ethyl-3,3-dimethyl-6-nitroindoline spiropyranyl methacrylate, Mix and stir 0.075g of n-hexadecane and 0.025g of azobisisobutyronitrile evenly, then disperse in 10mL of CTAC aqueous solution with a concentration of 0.005g / mL, ultrasonic emulsify until a stable and uniform miniemulsion is formed, and react at 75°C for 3 hours Finally, an optical switch nanoparticle a is obtained.

[0058] (2) Mix and stir 0.40g of styrene, 0.10g of divinylbenzene, 0.004g of p-DTPACO, 0.075g of n-hexadecane, and 0.025g of azobisisobutyronitrile, and then disperse them in the concentration of 0.005g / mL Ultrasonic emulsification in 10 mL of CTAC aqueous solution to form a stable and uniform miniemulsion, and react at 75° C. for 3 hours to obtain nanoparticles b.

[0059] (3) Composi...

Embodiment 3

[0061] A composite optical switch nanoparticle that can be adjusted to stable white light, the specific steps are as follows:

[0062] (1) 0.40g of styrene, 0.10g of divinylbenzene, 0.008g of p-DTPACO, 0.020g of ethyl-3,3-dimethyl-6-nitroindoline spiropyranyl methacrylate, Mix and stir 0.075g of n-hexadecane and 0.025g of azobisisobutyronitrile evenly, then disperse in 10mL of CTAC aqueous solution with a concentration of 0.015g / mL, ultrasonic emulsify until a stable and uniform miniemulsion is formed, and react at 75°C for 3 hours Finally, an optical switch nanoparticle a is obtained.

[0063] (2) Mix and stir 0.40g of styrene, 0.10g of divinylbenzene, 0.008g of p-DTPACO, 0.075g of n-hexadecane, and 0.025g of azobisisobutyronitrile, and then disperse them in the concentration of 0.015g / mL Ultrasonic emulsification in 10 mL of CTAC aqueous solution to form a stable and uniform miniemulsion, and react at 75° C. for 3 hours to obtain nanoparticles b.

[0064] (3) Composite two...

PUM

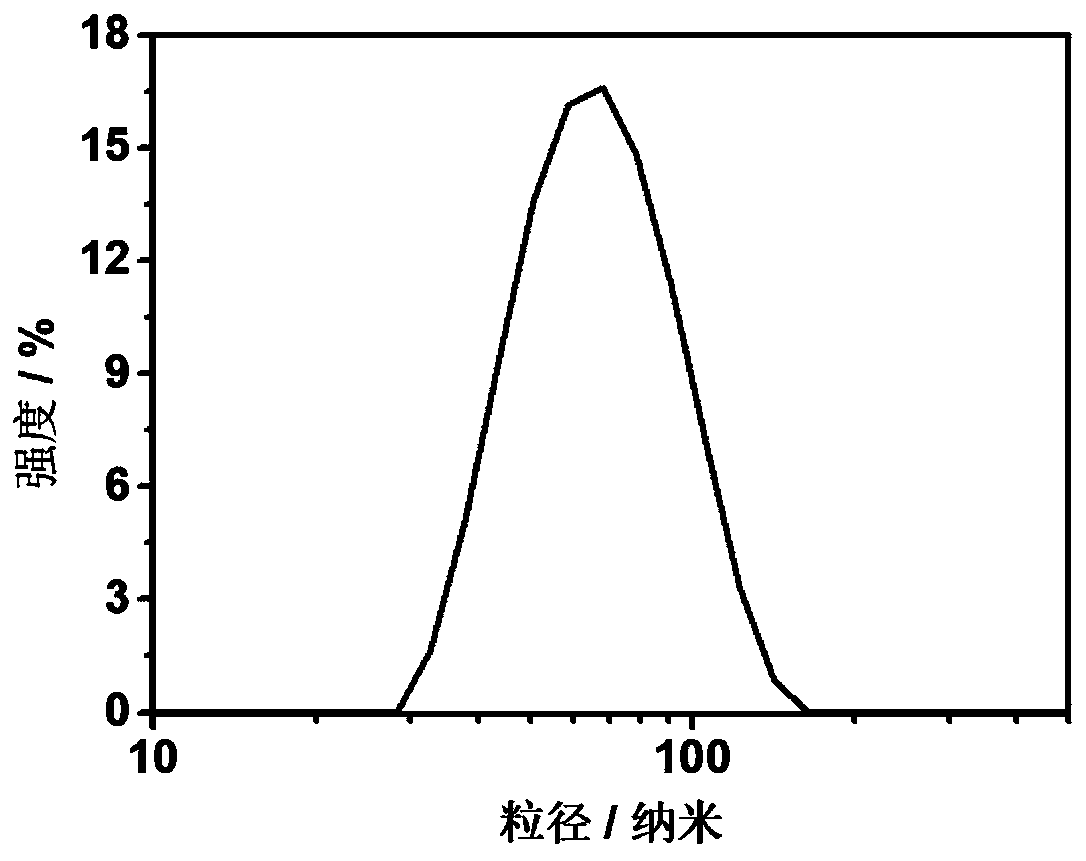

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com