Compound additive for high-light, heat-resisting and low-shrinkage polypropylene

A composite additive, polypropylene technology, applied in the field of composite additives, can solve the problems of reduced performance, increased specific gravity, reduced processing performance, etc., to achieve the effects of reduced shrinkage, large shrinkage, and improved gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

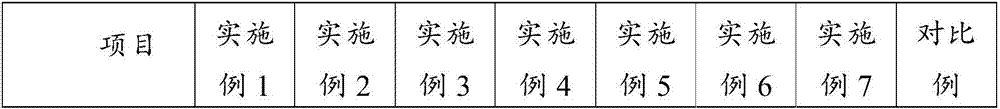

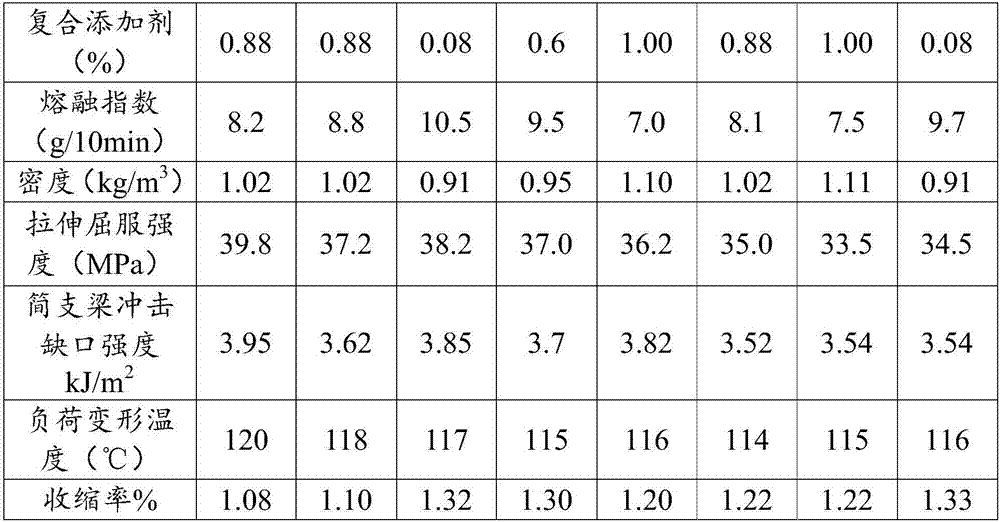

Examples

Example Embodiment

[0025] Example 1

[0026] An embodiment of the composite additive for high-light, heat-resistant and low-shrinkage polypropylene described in the present invention, the composite additive for high-light, heat-resistant and low-shrinkage polypropylene described in this embodiment comprises the following components by weight: 5 parts of silicide, 10 parts of nucleating agent, 15 parts of sodium benzoate, 15 parts of antioxidant, 15 parts of calcium stearate, 20 parts of high-temperature lubricant and 800 parts of superfine talcum powder.

[0027] Wherein, the silicide is silicon dioxide, and the nucleating agent is a mixture of dibenzylidene xylitol and 1,3:2,4-di(p-methylbenzylidene) sorbitol; the dibenzylidene The weight ratio of benzyl xylitol and 1,3:2,4-bis(p-methylbenzylidene)sorbitol is dibenzylidene xylitol:1,3:2,4-bis(p-methylbenzylidene) Benzylidene) sorbitol=1:1; The antioxidant is three [2.4-di-tert-butylphenyl] phosphite and tetrakis [β-(3,5-di-tert-butyl-4-hydroxy...

Example Embodiment

[0028] Example 2

[0029] An embodiment of the composite additive for high-light, heat-resistant and low-shrinkage polypropylene described in the present invention, the composite additive for high-light, heat-resistant and low-shrinkage polypropylene described in this embodiment comprises the following components by weight: 5 parts of silicide, 10 parts of nucleating agent, 15 parts of sodium benzoate, 15 parts of antioxidant, 15 parts of calcium stearate, 20 parts of high-temperature lubricant and 800 parts of superfine talcum powder.

[0030] Wherein, the silicide is silicon dioxide, the nucleating agent is a mixture of dibenzylidene xylitol and aryl carboxylic acid metal salt; the antioxidant is tris[2.4-di-tert-butylphenyl] Phosphate ester; the high-temperature lubricant is pentaerythritol stearate.

Example Embodiment

[0031] Example 3

[0032] An embodiment of the composite additive for high-light, heat-resistant and low-shrinkage polypropylene described in the present invention, the composite additive for high-light, heat-resistant and low-shrinkage polypropylene described in this embodiment comprises the following components by weight: 5 parts of silicide, 15 parts of nucleating agent, 10 parts of sodium benzoate, 15 parts of antioxidant, 15 parts of calcium stearate and 20 parts of high temperature lubricant.

[0033] Wherein, the silicide is silicon dioxide, a mixture of the nucleating agent aromatic amine compound and dibenzylidene xylitol; the antioxidant is tetrakis[β-(3,5-di-tert-butyl -4-hydroxyphenyl) propionate] pentaerythritol ester; the high-temperature lubricant is pentaerythritol stearate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap