Delustering agent for epoxy polyester powder coating

A powder coating, epoxy polyester technology, used in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor storage, difficult to obtain matting performance, matt powder gloss and storage can not achieve a win-win situation, etc. achieve good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

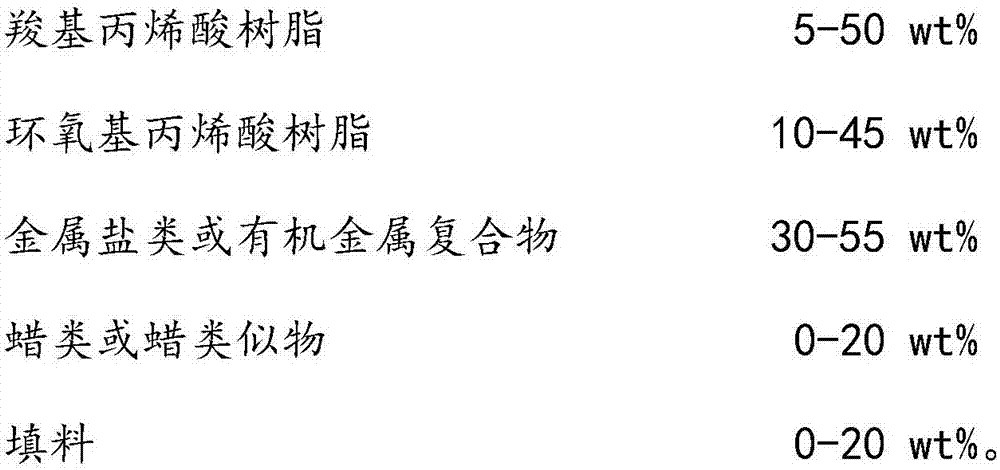

[0017] A kind of matting agent for epoxy polyester type matting agent powder coating is prepared from each component of following mass fraction:

[0018]

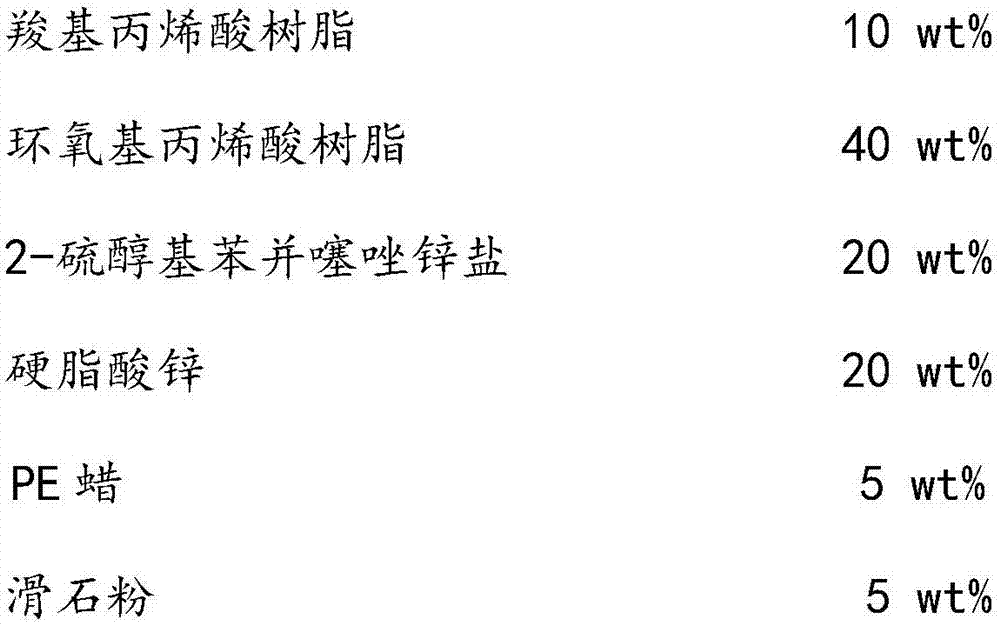

[0019] Among them, the carboxylated acrylic resin adopts the carboxylated acrylic resin of BASF, Germany 843, the acid value is 204mgKOH / g, and the Tg is 86°C; the epoxy-based acrylic resin is SA300 produced by Lu'an Jietongda New Material Co., Ltd., the epoxy equivalent is 300, and the Tg is 63°C;

[0020] The preparation method of the matting agent is as follows: firstly crush and sieve carboxyl acrylic resin and epoxy acrylic resin respectively, and the particle size is required to be controlled below 120 mesh, and then put them in a mixing tank according to the following formula and mix them thoroughly, and configure Matting agent A for epoxy polyester powder coating:

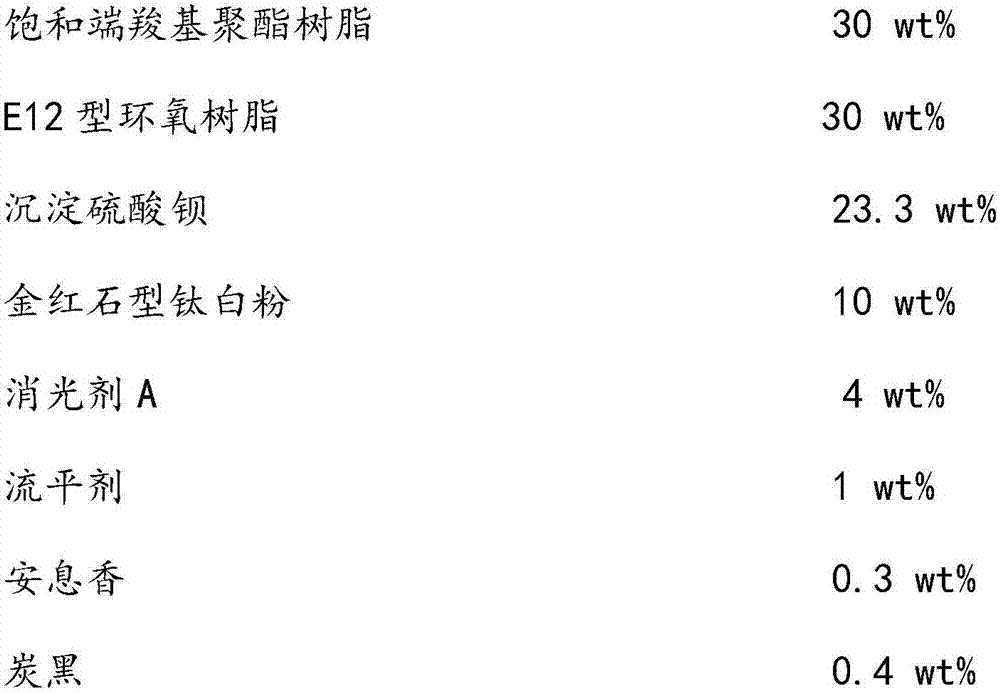

[0021] Preparation of epoxy polyester type matting powder coating:

[0022] (1) Pre-mixing: put the following raw materials into the mixing tank a...

Embodiment 2

[0030] The preparation process of this example is the same as that of Example 1, except that the carboxylated acrylic resin is SA151 from Lu’an Jietongda New Material Co., Ltd., its acid value is 155 mgKOH / g, and its Tg is 62°C to obtain a matting agent. b.

Embodiment 3

[0032] The preparation process of this example is the same as that of Example 1, except that the epoxy-based acrylic resin is SA700 produced by Lu'an Jietongda New Material Co., Ltd., with an epoxy equivalent of 750 and a Tg of 67°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com