Segmented string prestressed giant reticulated shell structure

A prestressed, giant technology, applied to building components, building structures, roofs, etc., can solve problems affecting structural durability and roof aesthetics, unfavorable roof layout and waterproof treatment, prominent problems of brace stability, etc., to achieve benefits Structural maintenance, reduction of occupancy, and avoiding the effect of pole instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

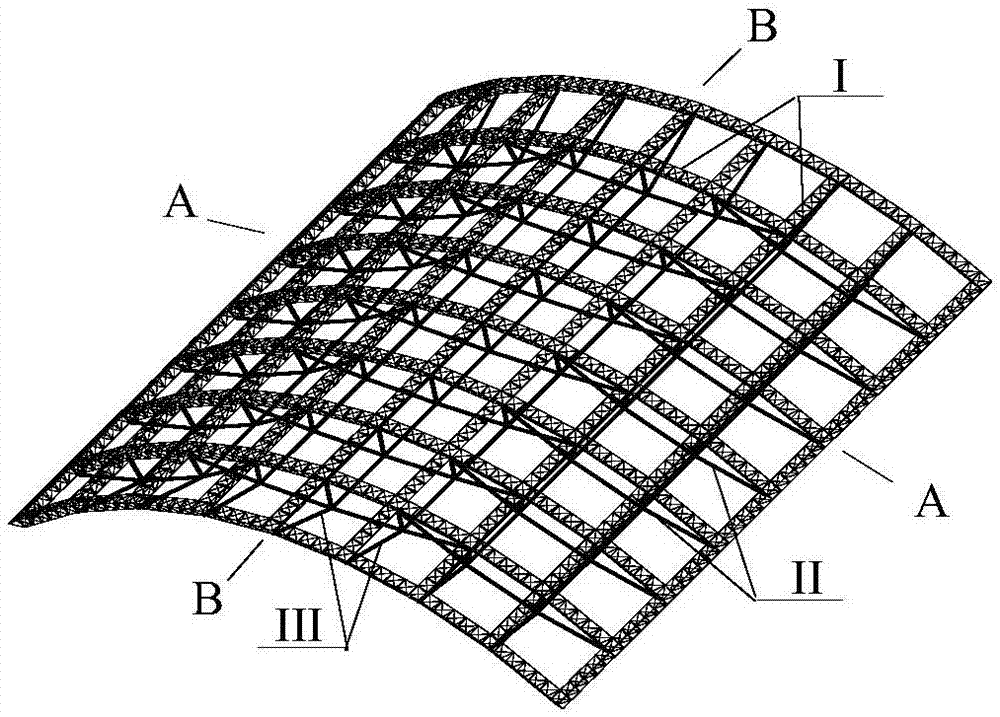

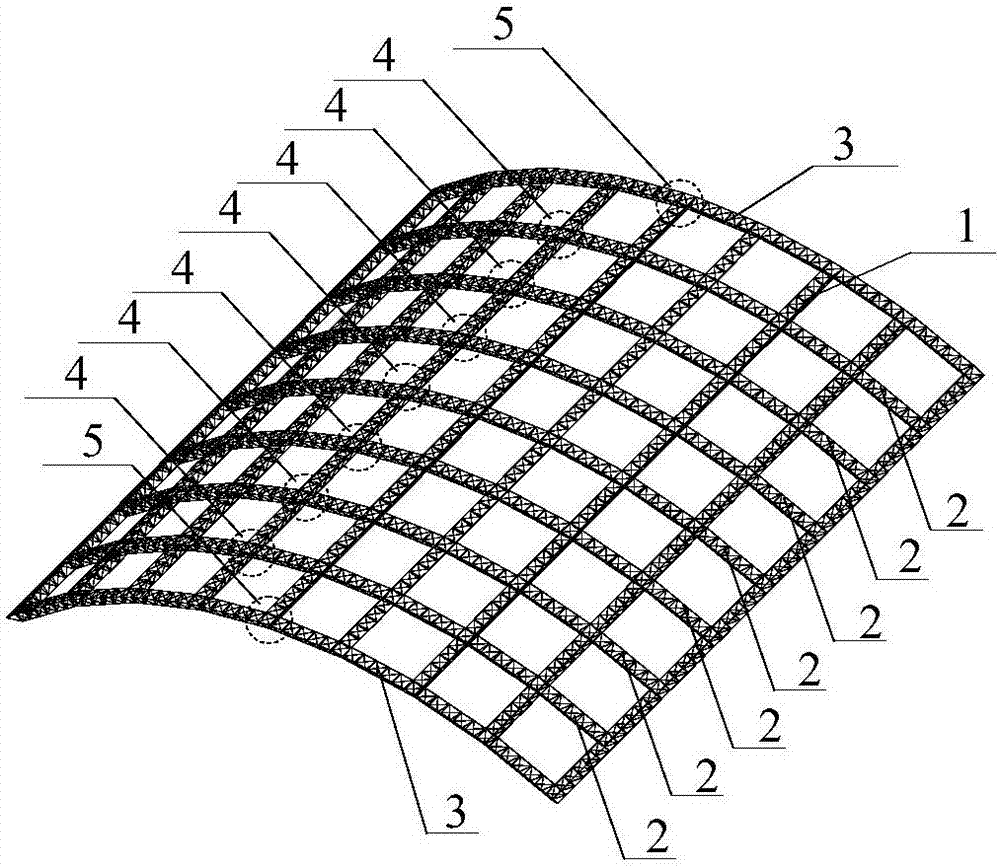

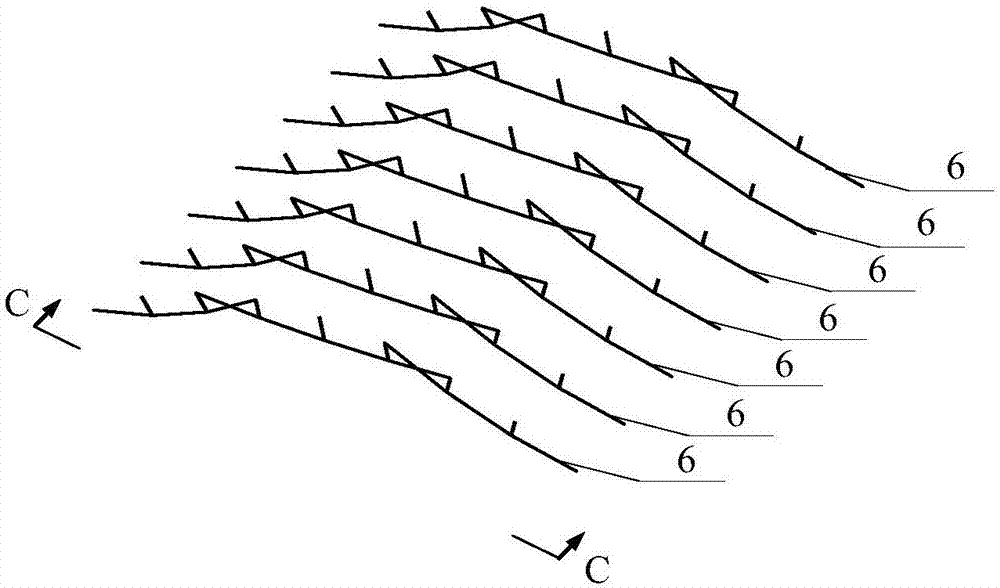

[0018] refer to Figure 1 to Figure 8 , the present embodiment includes a cross-dimensional truss system cylindrical giant reticulated shell I and a prestressed cable rod system II and a stabilizing cable system III arranged at the lower part of the cross-dimensional truss system cylindrical reticulated shell; the cross-dimensional truss system cylindrical giant reticulated shell The reticulated shell I is a large grid structure composed of several vertical three-dimensional trusses 1 and horizontal three-dimensional truss arches perpendicularly intersecting. The intersections with the transverse three-dimensional truss arches 3 at both ends constitute the main nodes 5 of the end transverse three-dimensional truss arches; Each segmented chord prestressed plane cable-strut system 6 is divided into three sections of approximately equal length, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com