Multi-ring all-fiber current transformer

A current transformer, all-fiber technology, used in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problem of the large size of the current transformer sensing ring, the inability to achieve differential current measurement, and the difficulty in manufacturing process guarantees, etc. problems, to achieve the effect of improving protection reliability, improving system reliability, and reducing system cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

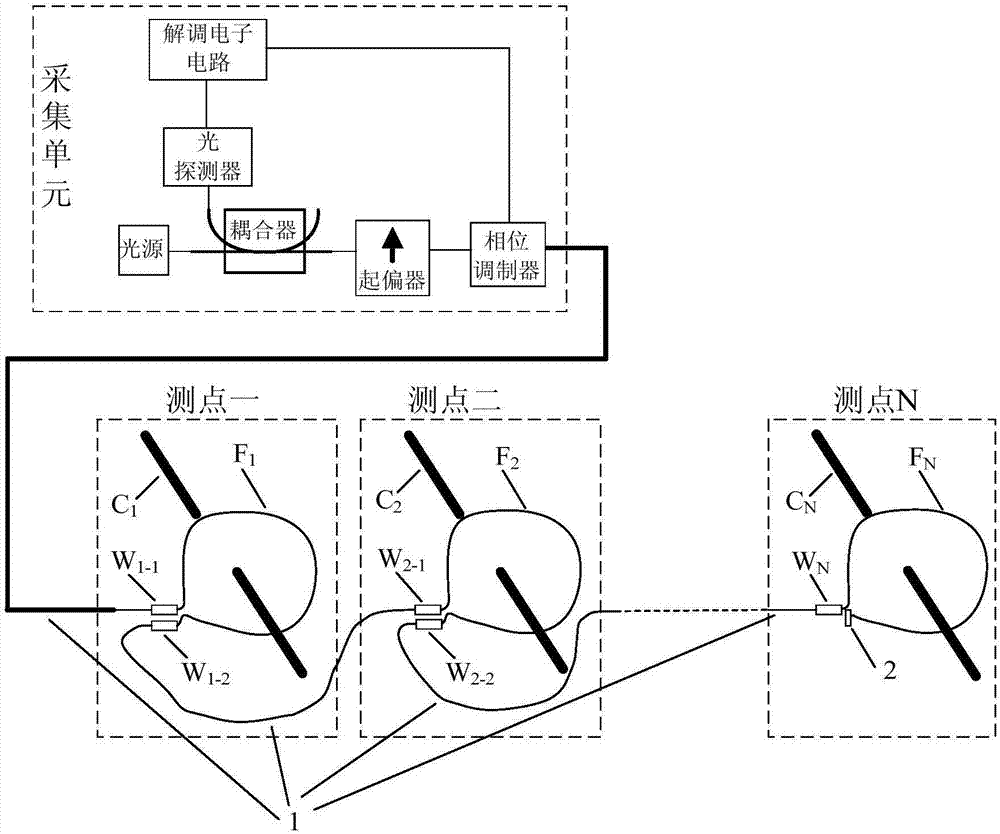

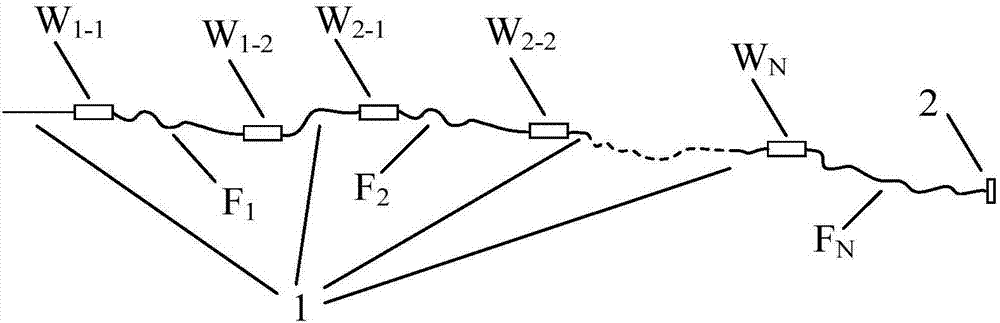

[0043] like Figure 5 As shown, it is a set of multi-ring optical CT for measuring line differential current. The multi-ring optical CT includes two sensing optical fiber rings, which are respectively wound on C 1 and C 2 On the conductor, the two optical fiber rings are connected through a polarization maintaining optical fiber 1 . The first optical fiber sensing loop of this optical CT consists of a λ / 4 wave plate W 1-1 , Sensing fiber F 1 and λ / 4 waveplate W 1-2 Composed of; the second optical fiber sensing loop consists of a λ / 4 wave plate W 2 , Sensing fiber F 2 and reflector 2. The winding directions of the sensing fibers of the two sensing fiber rings are opposite, so they exhibit positive and negative polarities respectively. Let the primary current value in the first optical fiber ring be I 1 , the phase shift caused by this current is φ 1 ; When the beam of light is transmitted to the second fiber optic ring, it is subject to I 2 The current influence produ...

Embodiment 2

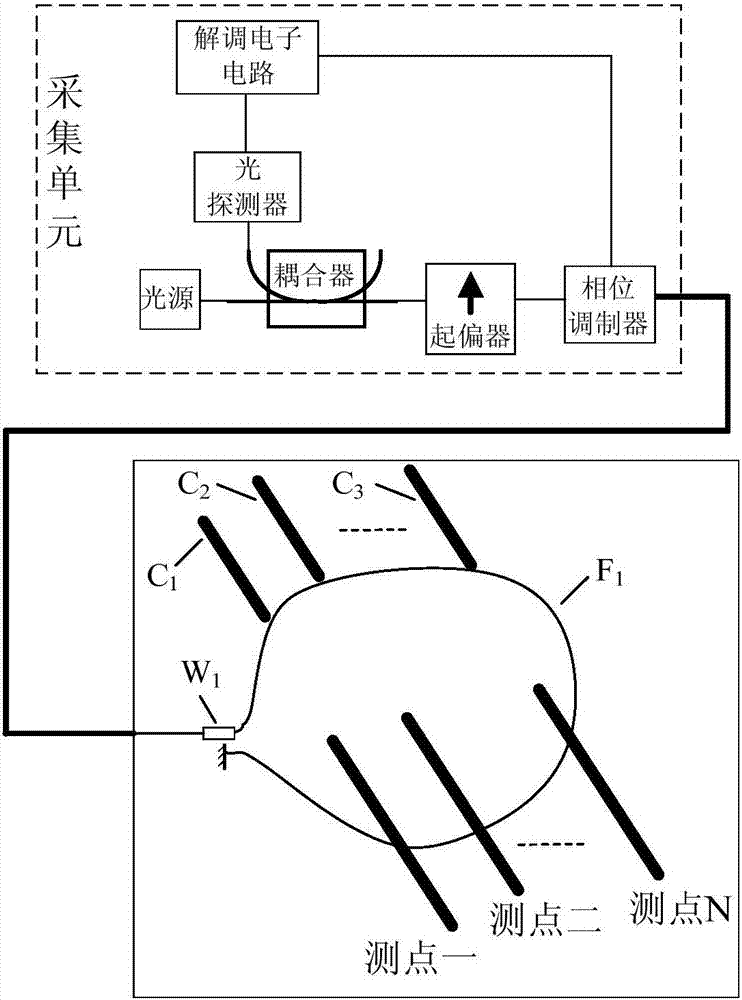

[0048] like Image 6 As shown, it is a set of multi-ring optical CT for measuring neutral point zero-sequence current. 1 、C 2 、C 3 Above, the three sensing rings are connected by polarization maintaining optical fiber 1 . The A-phase fiber optic sensing ring of the all-fiber optic current transformer consists of a λ / 4 wave plate W 1-1 , Sensing fiber F 1 and λ / 4 waveplate W 1-2 Composition; Phase B optical fiber sensing ring consists of λ / 4 wave plate W 2-1 , Sensing fiber F 2 and λ / 4 waveplate W 2-2 Composed; C-phase fiber sensing ring is composed of λ / 4 wave plate W 3 , Sensing fiber F 3 and reflector 2. The sensing fibers of the three sensing fiber rings are wound in the same direction, so they exhibit the same polarity. Let the primary current value in the A-phase optical fiber ring be I A , this current produces a phase shift of φ A ; I in phase B fiber optic ring B Current influence produces a phase shift φ B ; I in phase C fiber optic ring C Current infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com