Commodity delivery system for vending machine with compensation function and commodity delivery method thereof

An automatic vending machine and outlet technology, applied in the direction of handling coins or valuable banknotes, coin-free or similar appliances, coin-operated equipment for distributing discrete items, etc. problems such as low space utilization, to achieve the effect of convenient shipment and high system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

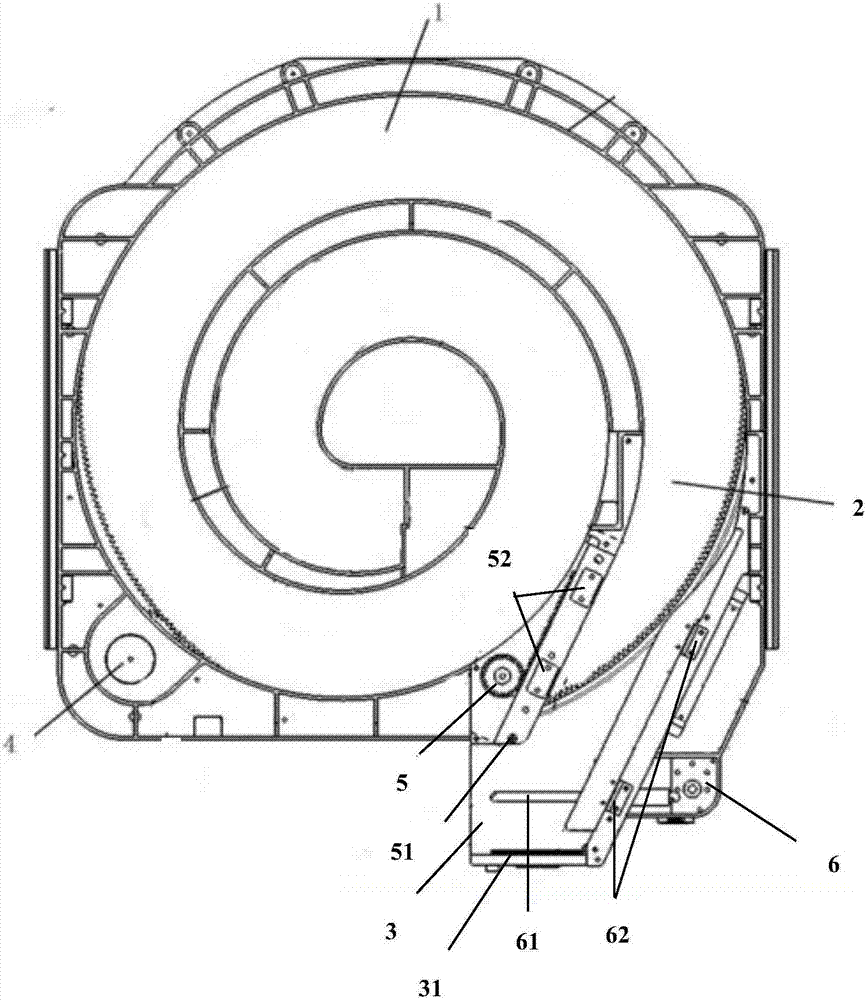

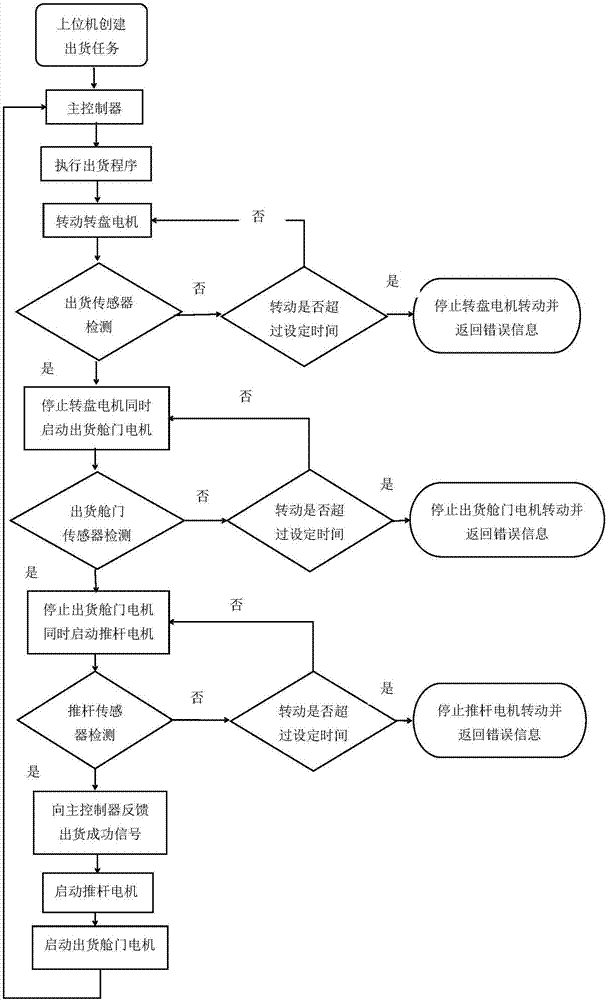

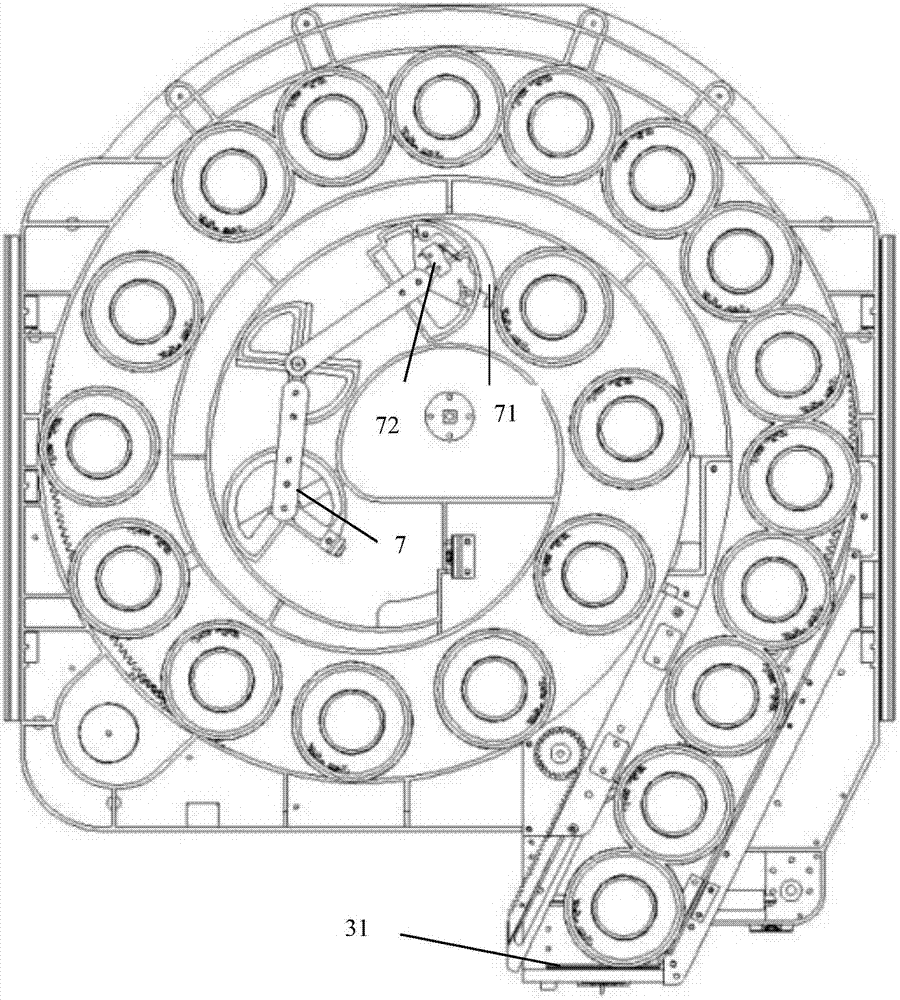

[0027] like figure 1 As shown, the present invention provides a delivery system for an automatic vending machine, including a spiral storage tank 1, a delivery port 3, and a delivery hatch 51. The delivery hatch 51 can be a gear lever or can be replaced by other conventional The structure, such as openable and closable door panels, etc., also includes a delivery device, which includes a turntable 2 and a push rod 61, the turntable 2 is used to push the goods to the delivery port 3, and the push rod 61 has a retractable Two states of returning and extending, which are used to push the goods out of the cargo hatch 5; the drive device includes a turntable motor 4, a push rod motor 6 and a cargo hatch motor 5, and the turntable motor 4 is used to drive the turntable to carry The goods move to the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com