Wolfberry combined harvesting equipment

A kind of equipment and wolfberry technology, applied in the field of agricultural and forestry machinery, can solve the problems of low fruit removal rate, difficulty in achieving high-frequency vibration, energy consumption, etc., and achieve the effects of improved harvesting efficiency, good adaptability, and good harvest quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

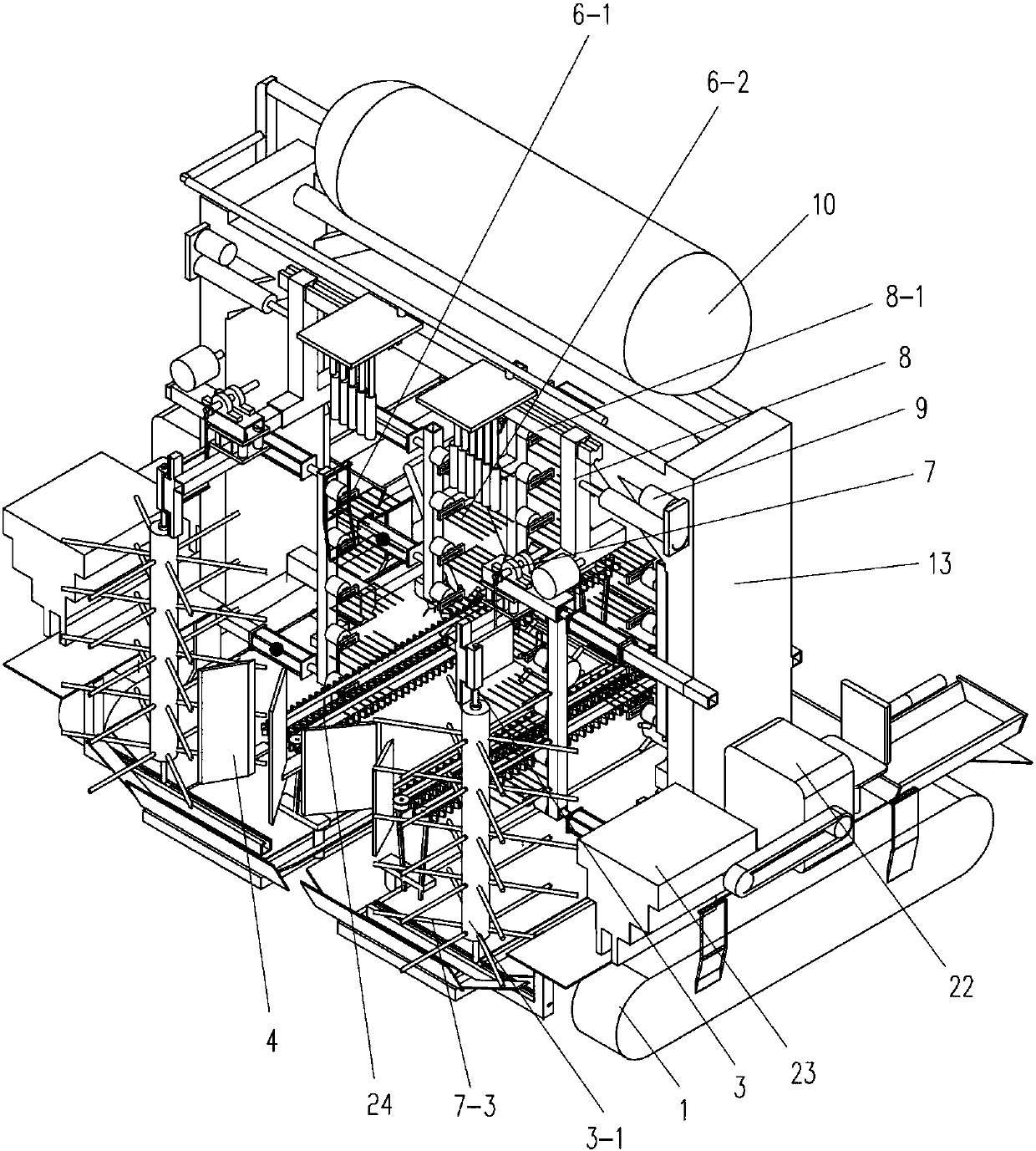

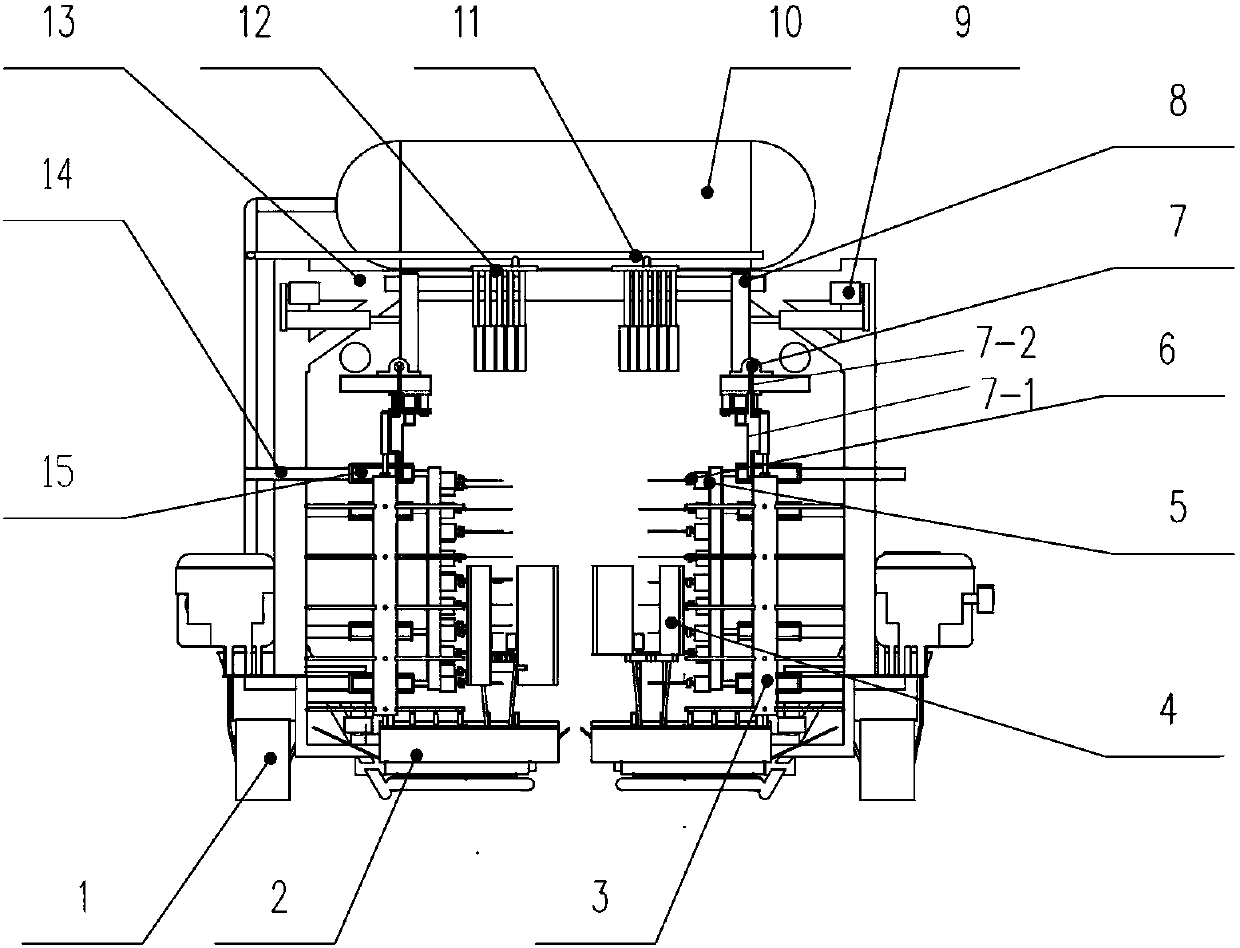

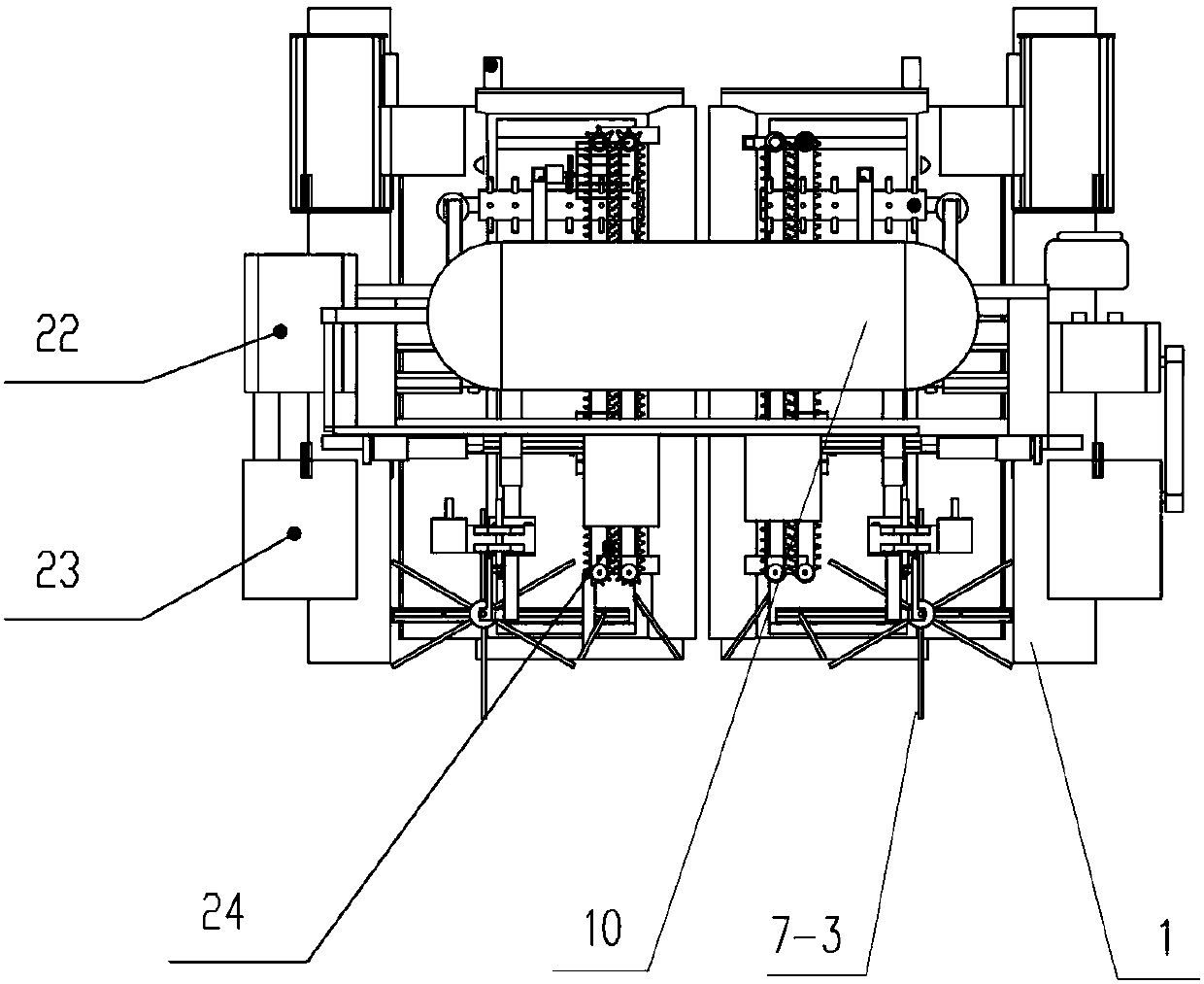

[0019] The wolfberry combined harvesting equipment of the present embodiment is as follows: Figure 1 to Figure 3 As shown, the crawler chassis 1 supports the gantry frame 13 , the rotary combing mechanism 3 , the gear-shaping vibration mechanism 6 and the clipping conveying mechanism 24 . The top of the front of the gantry frame 13 is fixed with a horizontal vertical axis traversing slide rail 8-1, and the both sides of the vertical axis traversing slide rail 8-1 form a horizontal movement pair with the vertical axis traversing carriage 8 respectively. The columns on both sides of the gantry frame 13 are respectively equipped with electric screw rods 9 that are connected to the adjacent vertical shaft traverse carriage 8 as a horizontal drive mechanism. The electric screw rod 9 forms a screw pair with the corresponding vertical shaft traverse carriage 8, so the The rotation of the screw becomes the translation of the vertical axis traversing carriage 8 .

[0020] The lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com