Connecting device for abrasive extrusion grinding in oil duct hole and nozzle hole of needle valve body

A technology of extrusion grinding and connecting device, applied in the field of mechanical processing, can solve the problems of reduced machine tool processing performance, weakened pressure, low practicability, etc., and achieves the effects of expanding processing range, improving atomization performance, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] Such as Figure 4 and Figure 5 As shown, the connection device of this embodiment is arranged between the base and the pressure head of the hydraulic grinding and extrusion machine tool, the top and the pressure head are sealed by a rubber gasket, and the bottom is connected to the needle valve body.

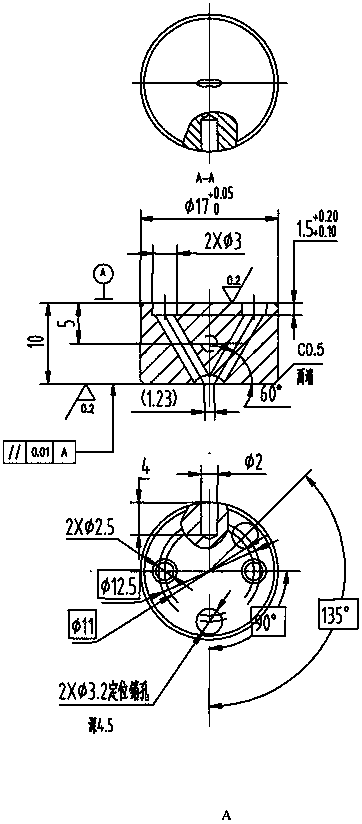

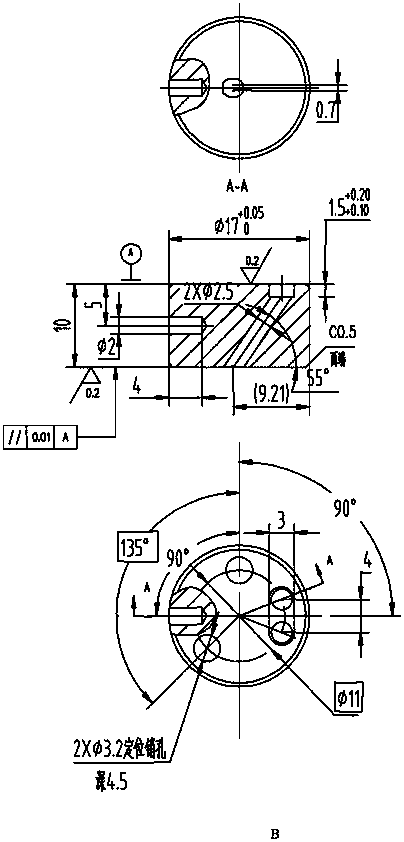

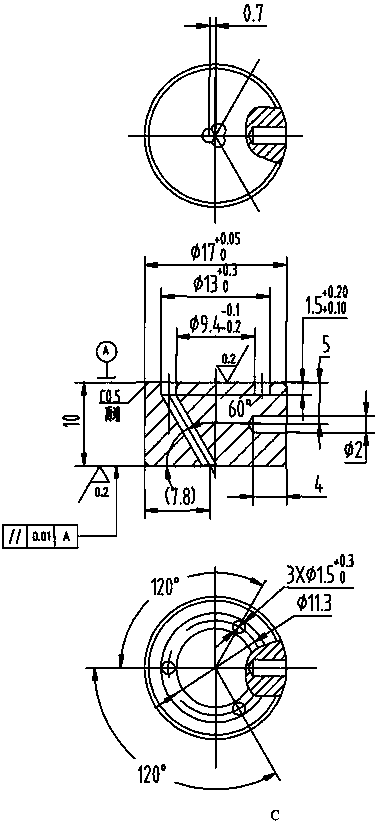

[0039] Specifically, as Figure 6 to Figure 8 As shown, the connection device of this embodiment includes three parts: positioning sleeve 3, liquid valve 1 and pin 2. The positioning sleeve 3 is cylindrical. The top of the body is embedded in the lower part of the positioning sleeve 3 and docked with the liquid valve. The pin 2 passes through the positioning sleeve 3 and the liquid valve 1 from the side and fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com