Composite ejecting mechanism

A push-out mechanism and composite technology, applied in the field of machinery, can solve the problems of product yield drop, product damage, strong adhesion, etc., and achieve the effect of smooth push-out process, reduction of damage rate, and prevention of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

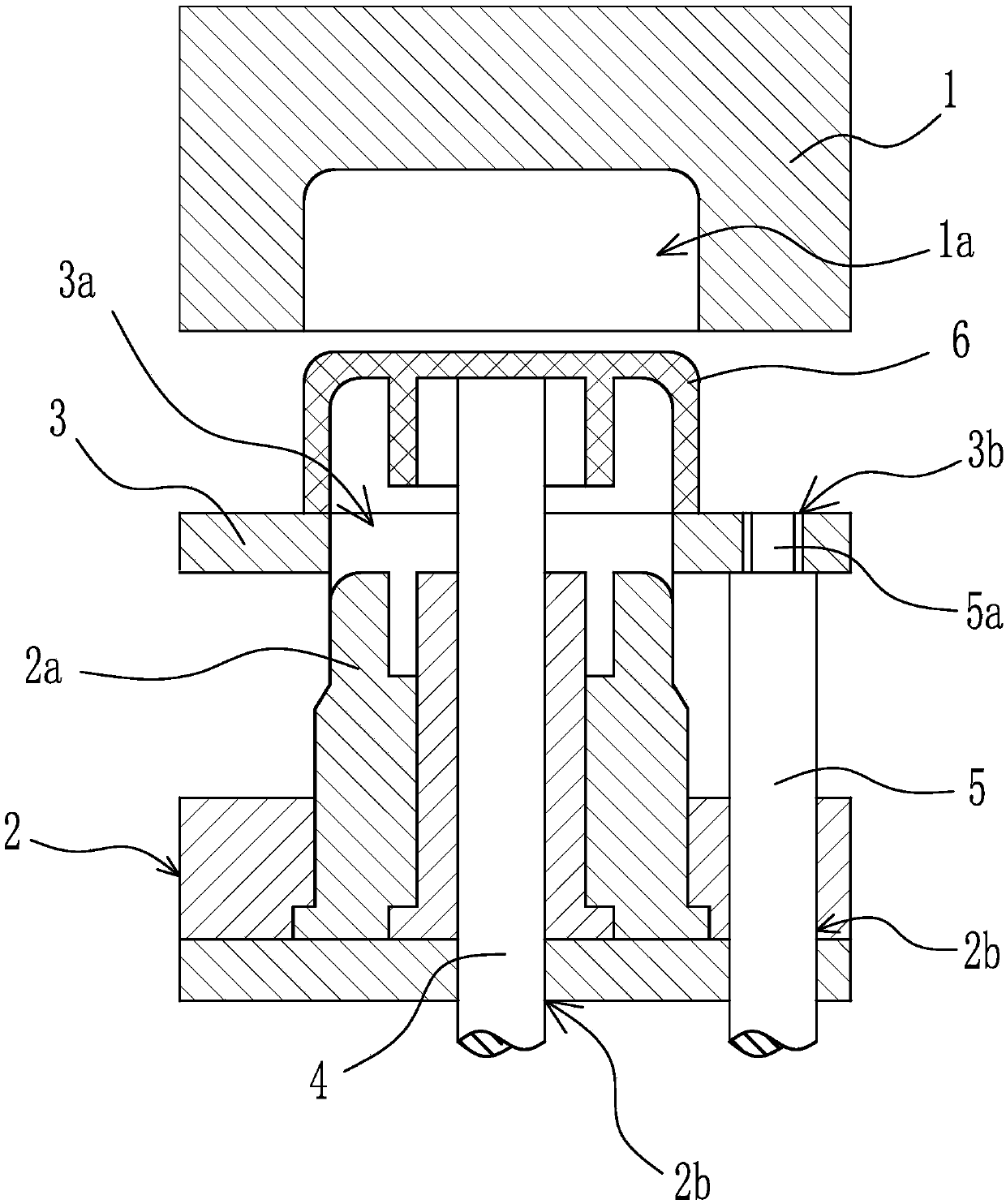

[0014] Such as figure 1 As shown, the composite push-out mechanism is used to release the product 6 from the mold. The mold includes a fixed template 2 and a movable template 1. The fixed template 2 is set opposite to the movable template 1. The composite push-out mechanism includes a pusher plate 3, at least one Main push rod 4 and at least one auxiliary push rod 5, attached figure 1 Only a main push rod 4 and an auxiliary push rod 5 are schematically drawn in the drawing. The pusher plate 3 is arranged between the fixed template 2 and the movable template 1, the pusher plate 3 is provided with a through hole 3a, the fixed template 2 has a convex mold part 2a for forming the product 6, and the movable template 1 has a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com