Continuous IC burning device and burn method thereof

A programming socket and pin technology, applied in transportation and packaging, conveyors, software deployment, etc., can solve the problems of long manual operation time, cumbersome operation, single IC programming, etc., and achieve a high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

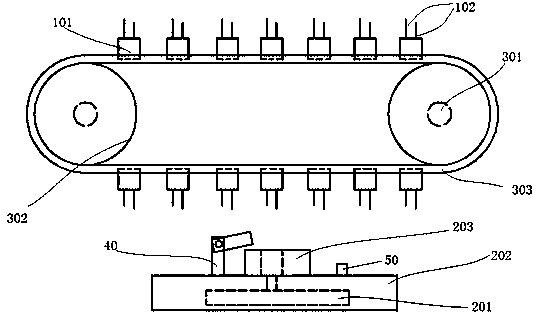

[0023] like figure 1 As shown, this embodiment provides an IC continuous programming device, which is characterized in that it includes: IC: including a chip 101 and a pin 102, the pin 102 is arranged on the surface of the chip 101, and the chip 101 and the pin 102 are connected in communication; Burner: The burner includes a data output unit 201, a base 202 and a burner base 203, the data output unit 201 is set in the base 202, the burner base 203 is set on the surface of the base 202, and the burner base 203 is connected to the boot The shape of the pin 102 is matched; the data output unit 201 is connected with the programming seat 203; the transmission assembly: includes a stepping motor 301, a transmission gear 302 and a transmission belt 303; the output shaft of the stepping motor 301 is connected with the transmission gear 302 axis, step The feeder motor 301 can drive the transmission gear 302 to rotate along the axis of the transmission gear 302; the inside of the trans...

Embodiment 2

[0030] This embodiment provides an IC continuous programming device, including: IC: including a chip 101 and pins 102, the pins 102 are arranged on the surface of the chip 101, and the chip 101 and the pins 102 are connected in communication; burner: burner Including a data output unit 201, a base 202 and a burning base 203, the data output unit 201 is arranged in the base 202, the burning base 203 is arranged on the surface of the base 202, and the burning base 203 matches the shape of the pin 102; the data The output unit 201 is communicatively connected with the programming seat 203; the transmission assembly: includes a stepping motor 301, a transmission gear 302 and a transmission belt 303; the output shaft of the stepping motor 301 is connected to the transmission gear 302 axis, and the stepping motor 301 can drive the transmission gear 302 rotates along the axis of the transmission gear 302; the inside of the transmission is provided with a protrusion that meshes with th...

Embodiment 3

[0032] This embodiment provides an IC continuous programming device, including: IC: including a chip 101 and pins 102, the pins 102 are arranged on the surface of the chip 101, and the chip 101 and the pins 102 are connected in communication; burner: burner Including a data output unit 201, a base 202 and a burning base 203, the data output unit 201 is arranged in the base 202, the burning base 203 is arranged on the surface of the base 202, and the burning base 203 matches the shape of the pin 102; the data The output unit 201 is communicatively connected with the programming seat 203; the transmission assembly: includes a stepping motor 301, a transmission gear 302 and a transmission belt 303; the output shaft of the stepping motor 301 is connected to the transmission gear 302 axis, and the stepping motor 301 can drive the transmission gear 302 rotates along the axis of the transmission gear 302; the inside of the transmission is provided with a protrusion that meshes with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com