Material transferring case for tungsten steel production

A transfer box and material technology, applied in the direction of unloading devices, transportation and packaging, containers to prevent mechanical damage, etc., can solve the problems of low transfer efficiency, collision, damage, etc., to avoid damage to the workpiece and improve the efficiency of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

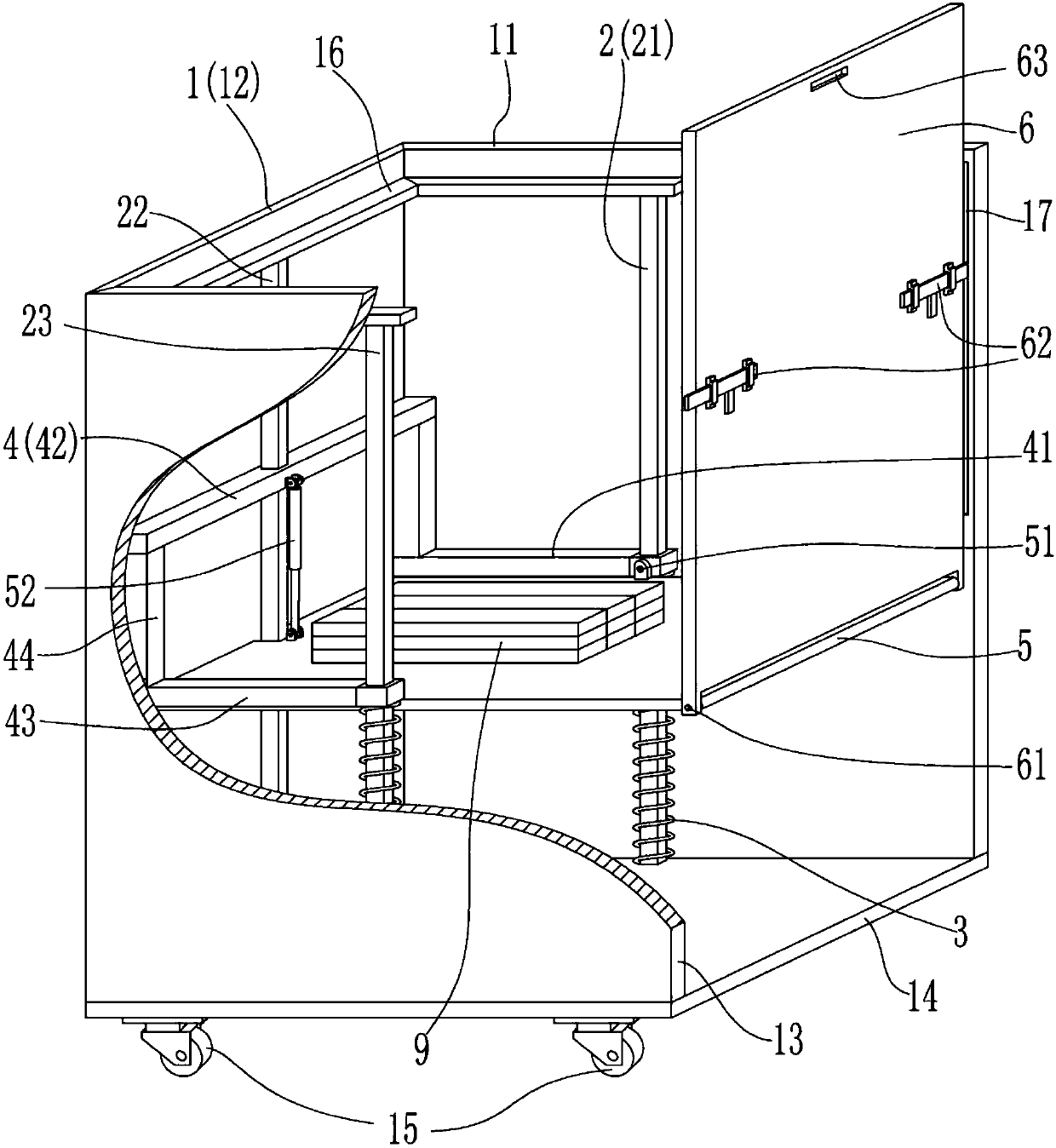

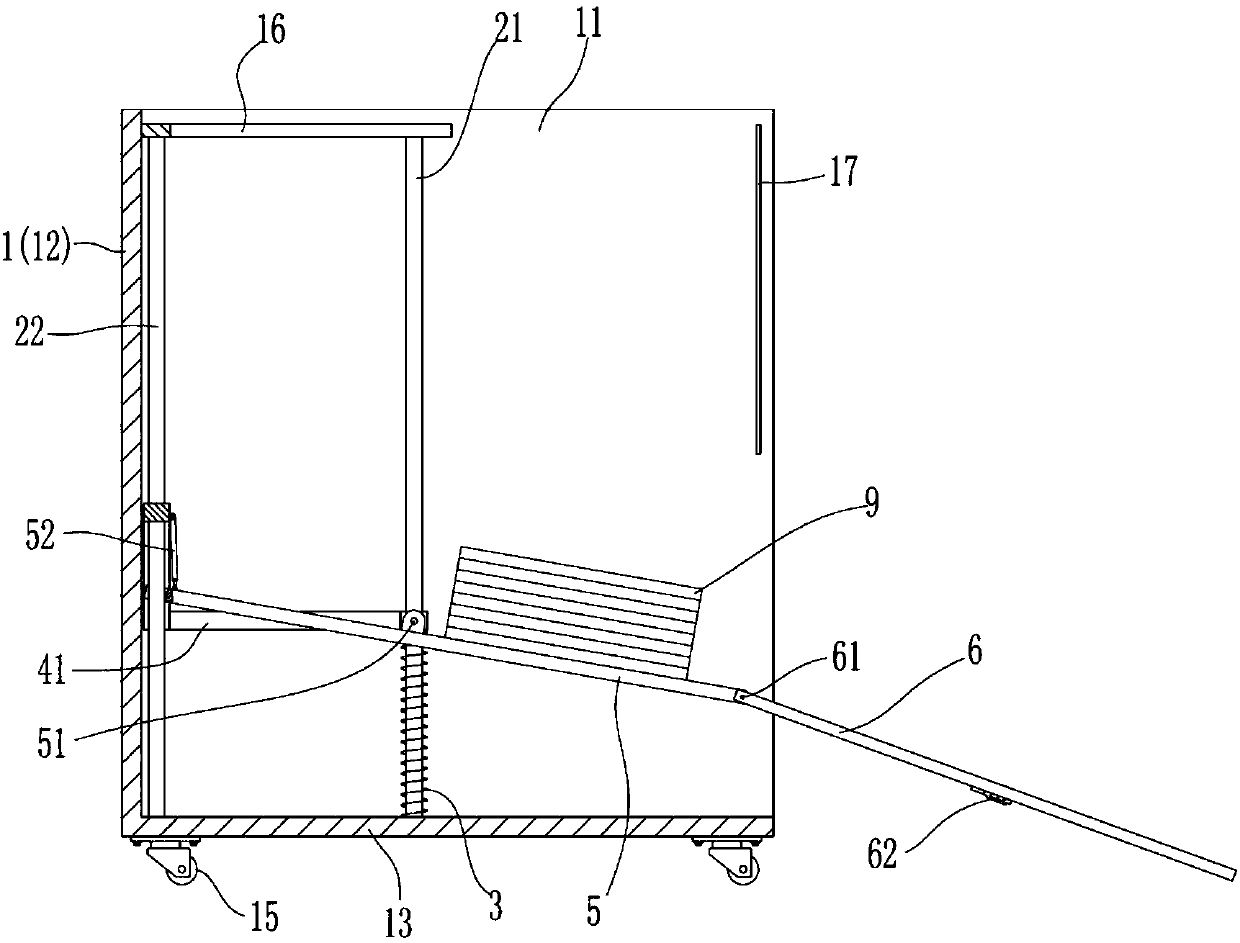

[0018] Such as figure 1 with figure 2 As shown, the present invention proposes a material transfer box for the production of tungsten steel, which includes a cuboid box body 1 with openings on one side and top, a plurality of guide columns 2 vertically fixed inside the box body 1, sleeved on The spring 3 on the guide column 2, the bracket 4 supported on the upper end of the spring 3 and positioned in the box body 1, the load-bearing plate 5 hinged on the bracket 4 and positioned in the box body 1 through the horizontal first rotating shaft 51, and the load-bearing plate 5 positioned in the box body 1 through the horizontal first rotating shaft Two rotating shafts 61 are hinged on the door panel 6 at one end of the bearing plate 5, wherein:

[0019] The box body 1 includes a first side plate 11, a second side plate 12, a thi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap