Spinning assembly for production of industrial filaments used for nylon-66 air bags

A technology for spinning components and airbags, which is applied in the field of synthetic fiber production devices, can solve the problems of short service life of components, high cost of filter materials, and high leakage rate, so as to reduce production costs, reduce wool and end breakage rates, and porosity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

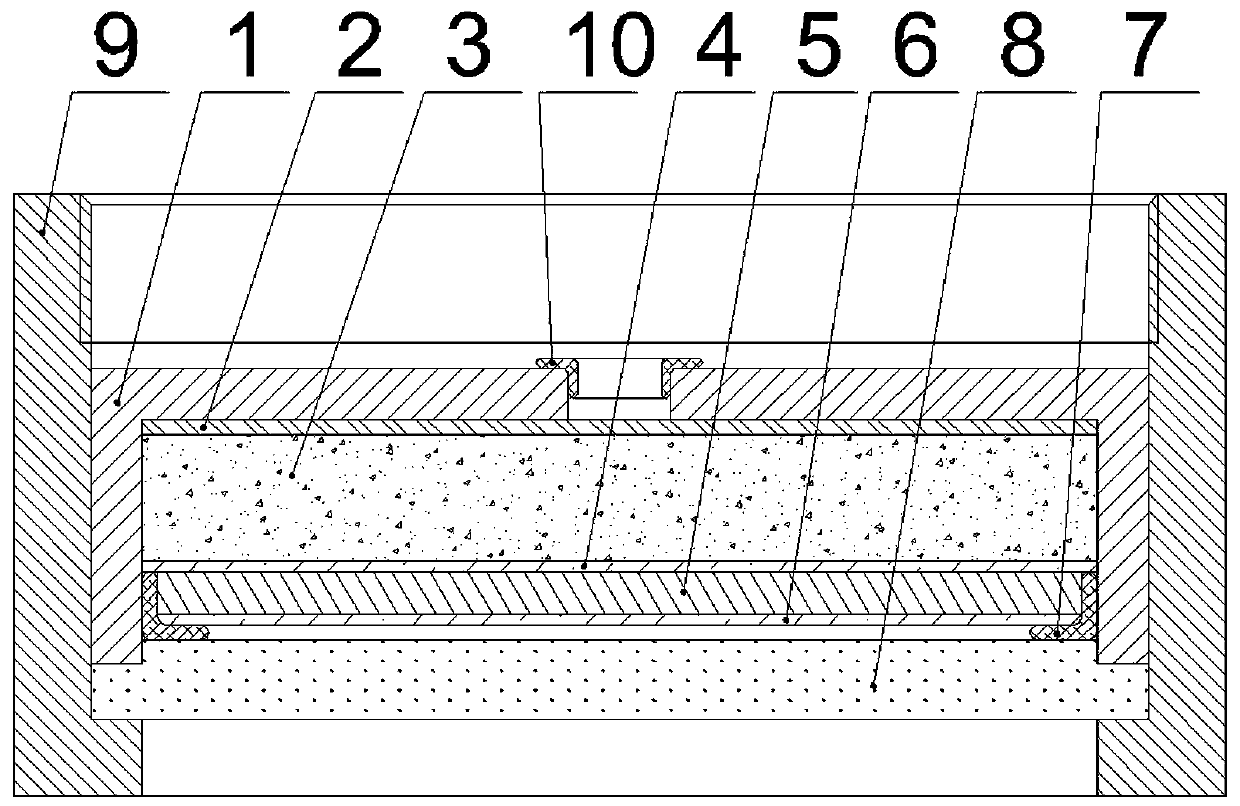

[0022] Embodiment 1: In this embodiment, if figure 1 As shown, a spinning assembly for the production of industrial filaments for nylon 66 airbags, including a sand box and a spinning assembly shell, one end of the sand box is open, and the middle part of the other end of the sand box is provided with a melt inlet , the sand box is provided with a filter screen, metal sand, the first metal fiber felt, a distribution plate, a second metal fiber felt, a first sealing ring, and a spinneret sequentially from the melt inlet end, and the distribution plate and There is a gap between the inner walls of the sand box, the first sealing ring is an L-shaped sealing ring including vertical sides and transverse sides, and the vertical side of the first sealing ring is clamped between the distribution plate and the inner wall of the sand box In the gap, the first sealing ring presses the second metal fiber felt onto the distribution plate. The axial direction of the spinneret is set in a st...

Embodiment 2

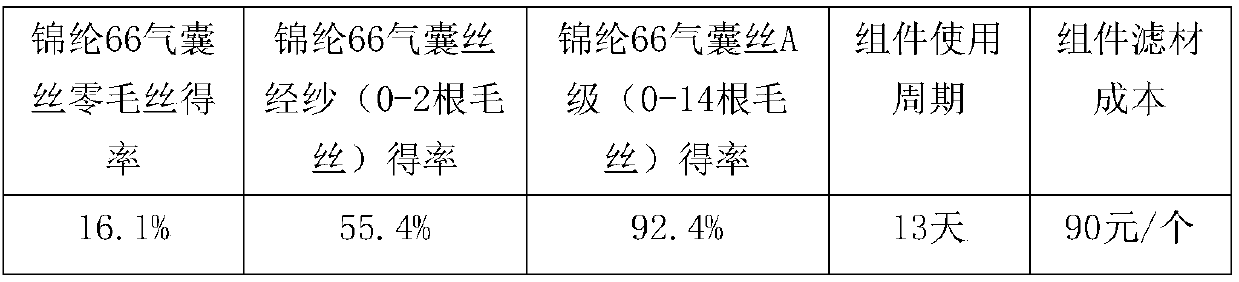

[0041] Embodiment two: this embodiment is basically the same as embodiment one, the difference is that metal sand composition (weight percentage): C-0.06%, Cr-37.0%, Fe-57.5%, Ni-0.68%, Si-4.76 %; the nominal specification of metal sand is 20-35 mesh (of which the ratio of 20-30 mesh is 85.0%, the ratio of 30-40 mesh is 10.0%, the ratio of 40-50 mesh is 3.9%, the ratio of 50-100 mesh is 1.1%); the specification of metal fiber felt is 300% head. Produce nylon 66 industrial filaments for airbags with a variety of 350dtex and a winding speed of 2800m / min.

[0042] The component usage effect is shown in Table 2:

[0043] The test result of table 2 embodiment 2

[0044]

[0045] Note: The cost of conventional multi-layer metal filter components is 180 yuan / piece, and the component life cycle is 8 days

Embodiment 3

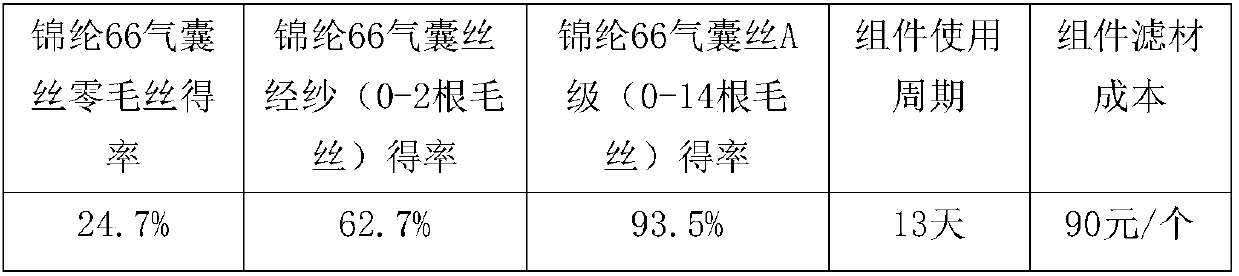

[0046] Embodiment three: this embodiment is basically the same as embodiment one, the difference is that the metal sand composition (percentage by weight): C-0.06%, Cr-37.0%, Fe-57.5%, Ni-0.68%, Si -4.76%;

[0047] The nominal specification of metal sand is 45-60 mesh (the ratio of 45-60 mesh is 95.0%, the ratio of 60-90 mesh is 4.0%, and the ratio of 90-100 mesh is 1.0%); the specification of metal fiber felt is 300 mesh. Produce nylon 66 industrial filaments for airbags with a variety of 350dtex and a winding speed of 2800m / min.

[0048] The effect of using components is shown in Table 3:

[0049] The test result of table 3 embodiment 3

[0050]

[0051]

[0052] Note: The cost of conventional multi-layer metal filter components is 180 yuan / piece, and the component life cycle is 8 days

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com