Radial shrinkage plastic tube for cone yarn dyeing

A technology for yarn dyeing and plastic tubes, which is applied in the field of dyeing cheeses, can solve the problems of color pattern, difference between inner and outer layers of products, and difficulty in dyeing liquid penetration, and achieves the advantages of convenient and reliable use, simple structure, and guaranteed dyeing quality Effect

Pending Publication Date: 2018-04-13

湖州新嘉怡丝织印花有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] During the dyeing process of the package yarn, it is necessary to use a loosing car to soften the package yarn, so that the next process of the package yarn, that is, the high temperature and high pressure dyeing machine, the original yarn roller is equipped with an upper roller with the same diameter on the tube body. The bottom and the lower bottom, the cylinder body and the upper bottom are vertically arranged, and the cylinder body and the lower bottom are also vertically arranged, and the pressure relief holes set on the cylinder body are perpendicular to the cylinder body, so that there is not enough dyeing paste entering through the upper bottom each time. The pressure difference flows to the yarn wound on the bobbin, so that after dyeing for a period of time, it is necessary to use a loosening car to loosen the bobbin and then dye it. After dyeing, use the winding setting to wind the bobbin Well, in order to obtain a bobbin with good shape and no sagging phenomenon; when the yarn of the above-mentioned yarn bobbin is dyed, various sizes of warps will occur due to factors such as water, high temperature and high pressure, and solvents encountered by the yarn during the dyeing process. Shrinkage, in severe cases, it will cause difficulty in penetrating the inside and outside of the dye solution, resulting in quality problems such as poor inner and outer layers of the product, color flowers, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

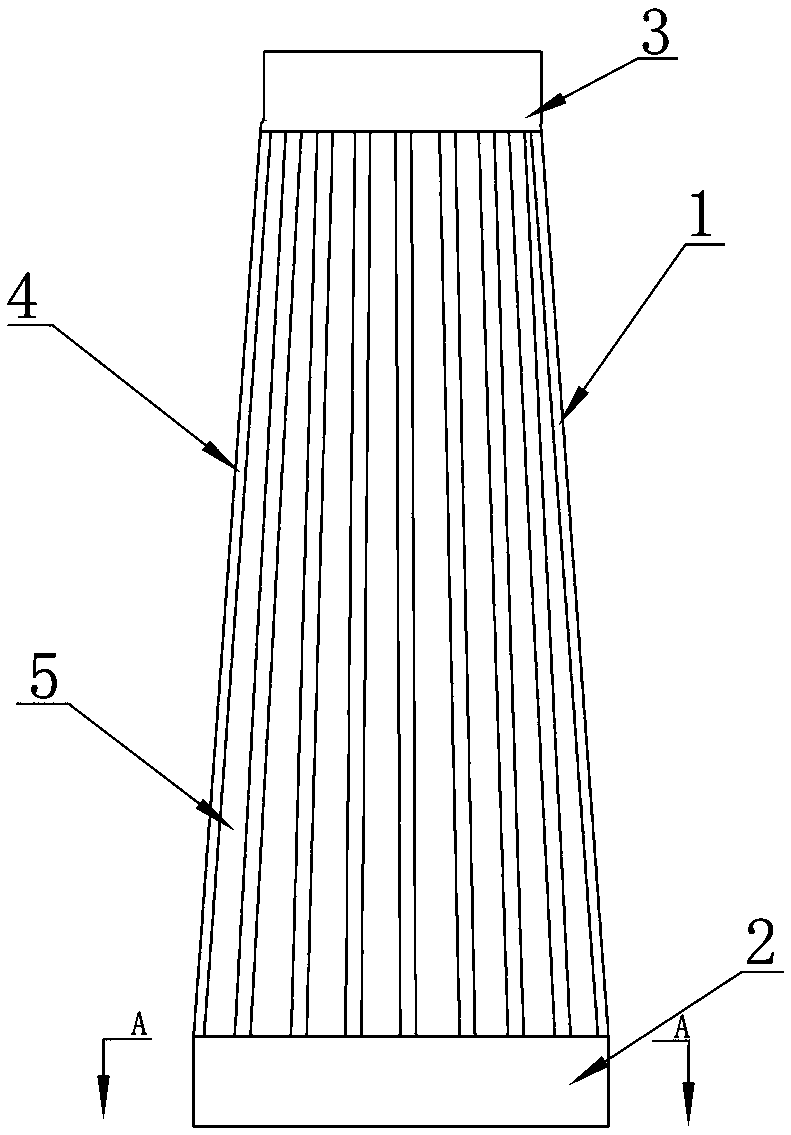

[0016] Embodiment: The present invention is made of high-molecular high-temperature-resistant plastic, and its shape is tapered and cylindrical. The outer diameter of the upper bottom (small head) is 55mm, the outer diameter of the lower bottom (big head) is 66mm, and the height of the tube body is 170mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

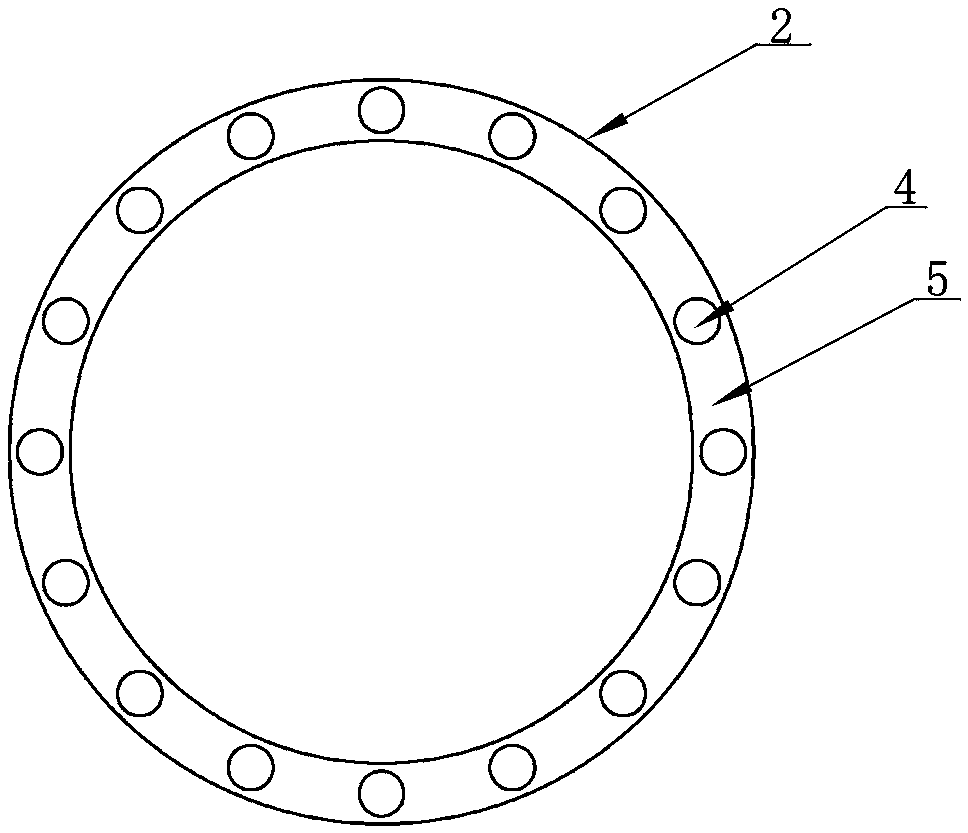

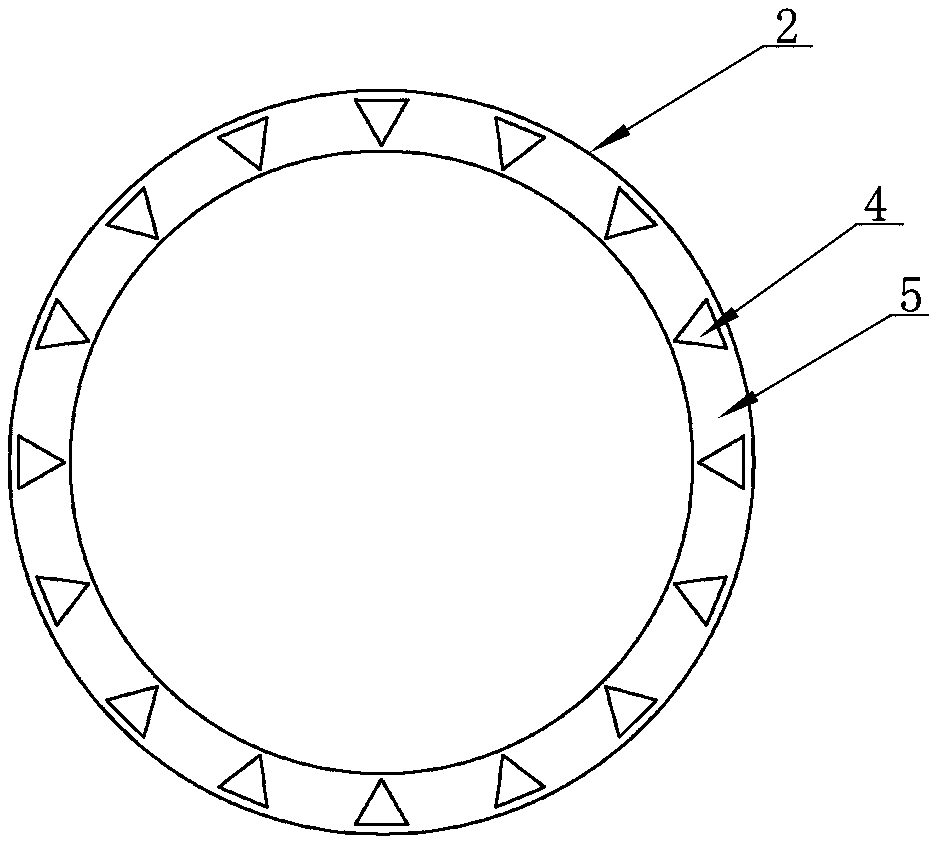

Disclosed is a radial shrinkage plastic tube for cone yarn dyeing. The plastic tube comprises a conical tube body and is characterized in that the upper and lower portions of the tube body are provided with an upper annular bottom and a lower annular bottom respectively, the conical tube body between the upper bottom and the lower bottom is formed by connecting axial rod pieces one by one, and a pressure relief gap larger than the width or diameter of the rod pieces on the same plane is formed between the adjacent rod pieces; the upper and lower ends of the rod pieces are connected to the inner side end edges of the annular body of the upper bottom and the lower bottom respectively, the outer diameter of the annular body of the lower bottom is larger than the outer diameter of the annularbody of the upper bottom, and the thickness of the annular body of the lower bottom is larger than the thickness of the annular body of the upper bottom; the plastic tube has the advantages that the structure is simple, use is convenient and reliable, on the basis of ensuring that the cone has the enough strength, the cone can be subjected to radial shrinkage along with yarn shrinkage in the dyeing process, and therefore the yarn product dyeing quality is ensured.

Description

technical field [0001] The invention relates to a radially shrinkable plastic tube for cheese dyeing, and belongs to the technical field of cheese dyeing. Background technique [0002] During the dyeing process of the package yarn, it is necessary to use a loosing car to soften the package yarn, so that the next process of the package yarn, that is, the high temperature and high pressure dyeing machine, the original yarn roller is equipped with an upper roller with the same diameter on the tube body. The bottom and the lower bottom, the cylinder body and the upper bottom are vertically arranged, and the cylinder body and the lower bottom are also vertically arranged, and the pressure relief holes set on the cylinder body are perpendicular to the cylinder body, so that there is not enough dyeing paste entering through the upper bottom each time. The pressure difference flows to the yarn wound on the bobbin, so that after dyeing for a period of time, it is necessary to use a l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B23/04

CPCD06B23/04

Inventor 何时荣

Owner 湖州新嘉怡丝织印花有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com