Prefabricated fabricated type anti-collision wall structure with pulley device

A prefabricated assembly, anti-collision wall technology, applied in road safety devices, instruments, roads, etc., can solve the problems of high maintenance costs, large accident damage, and insufficient energy consumption or mitigation of vehicle collisions, and achieves reasonable structural design. The effect of reducing the degree of impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

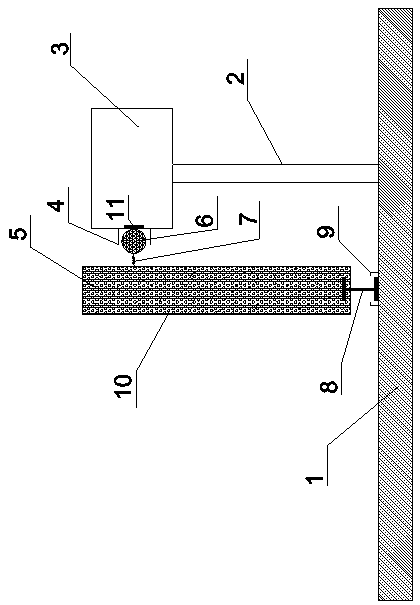

[0015] Such as figure 1 A prefabricated anti-collision wall structure with a pulley device is shown, including a driveway 1, steel columns 2, steel guardrails 3, steel track grooves 4, reinforced concrete prefabricated slab walls 5, pulleys 6, damping 7, I-shaped steel 8, steel track groove 9, panel wall finish 10 and alarm device 11, steel columns 2 and steel guardrail boards 3 fixedly connected to each other are respectively arranged on both sides of the roadway 1, and the steel guardrail boards 3 are A steel track groove 4 is connected, and one side of the reinforced concrete prefabricated slab wall 5 is flexibly connected to the steel track groove 4 through a pulley 6 and a damper 7. The lower part of the reinforced concrete prefabricated slab wall 5 is connected with an I-shaped steel 8, so The bottom of the I-shaped steel 8 is sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com