Steel structure connecting piece capable of being tensioned

A technology for steel structures and connectors, applied to building components, building structures, walls, etc., to achieve the effects of stable connection, wide application range, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

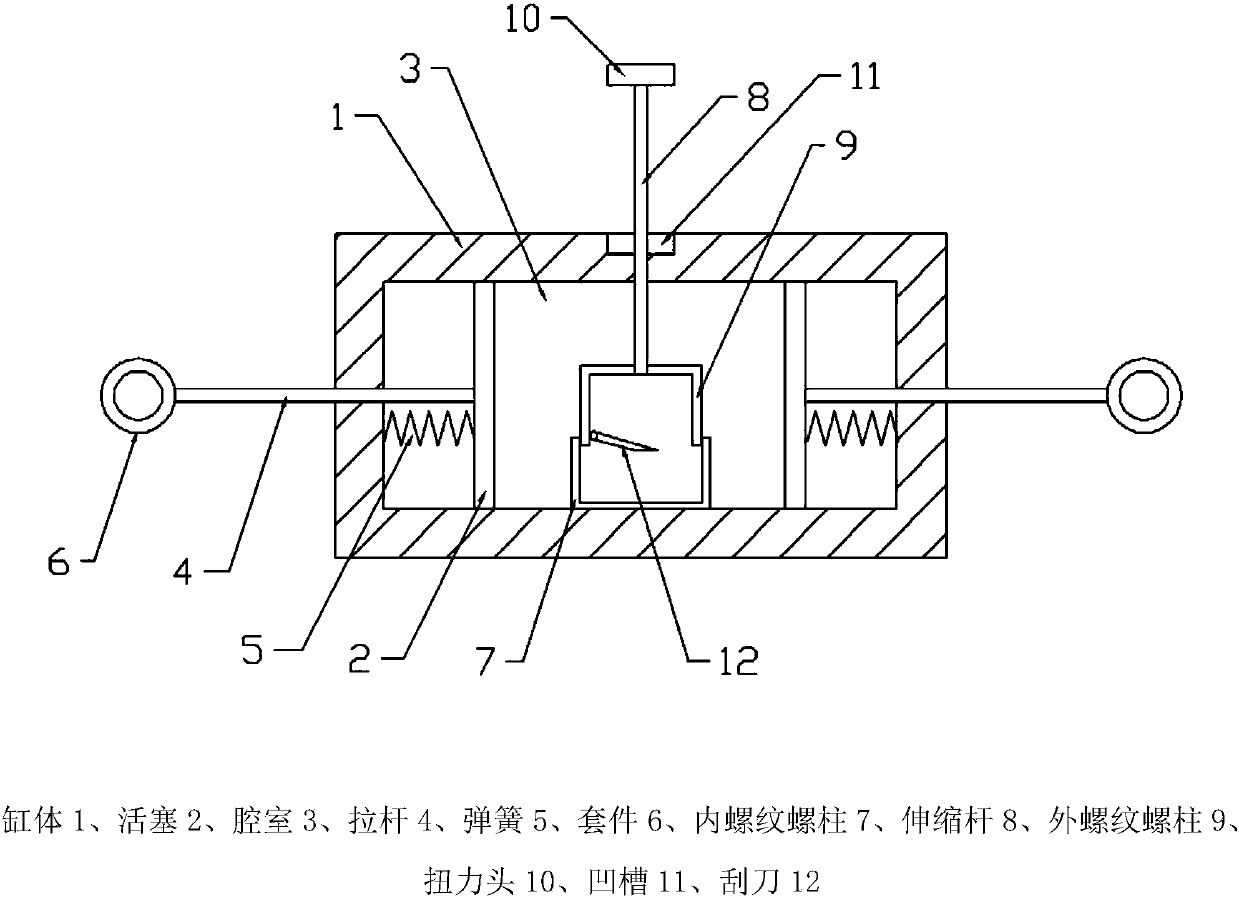

[0015] The reference signs in the drawings of the description include: cylinder 1, piston 2, chamber 3, pull rod 4, spring 5, kit 6, internally threaded stud 7, telescopic rod 8, externally threaded stud 9, torque head 10, Groove 11, scraper 12.

[0016] The embodiment is basically as attached figure 1 As shown: the tensionable steel structure connector of the present invention includes a cylinder 1 and two pistons 2 slidingly fitted in the cylinder 1, a sealed chamber 3 is formed between the two pistons 2 and the cylinder 1, The outer wall of the piston 2 is connected with a tie rod 4 and a spring 5, the spring 5 is connected with the inner wall of the cylinder body 1, the tie rod 4 is set through the cylinder body 1, and the end of the tie rod 4 placed outside the cylinder body 1 is buckled and connected with a kit 6 for fixing the steel structure , the inner bottom of the chamber 3 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com