The use method of the all-metal screw pump heavy oil injection and production integrated device

A screw pump, all-metal technology, applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of increasing the operation cost and construction risk, reducing the service life of the screw pump, and lowering the error, etc., to reduce the The probability of occurrence of safety accidents, the effect of reducing operating costs, and reducing potential safety hazards

Inactive Publication Date: 2019-10-01

刘玉友

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing problem is that although the screw pump does not need to be completely lifted out of the wellhead, it is only lifted for a certain distance, which can reduce the working time, but it is still necessary to lift the rotor part of the screw pump, and every time the metal rotor is lifted and lowered There may be a wear and tear on the metal stator, and there will generally be errors in its lowering, which may cause a collision with the stator every time the all-metal rotor is lowered, thereby reducing the service life of the screw pump. Although the invention also uses some Technical means to reduce its collision or wear, but there is still the possibility of wear or collision, reducing the service life of the screw pump; in addition, the lifting of the rotor of the screw pump requires large-scale hoisting equipment, which also increases the operating cost and construction. the danger of

The problem with this invention is that the rotor part of the screw pump still needs to be lifted up, and every time the metal rotor is lifted and lowered, the metal stator may be worn out once, although the process of lifting and lowering it uses a motor and a injection pump. The integrated wellhead of gas production and oil production is completed, which reduces the error and the probability of collision between the rotor and the stator, but this still cannot avoid the wear and tear on the stator every time the all-metal rotor is lowered and lifted, so it will still reduce the performance of the screw pump. service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

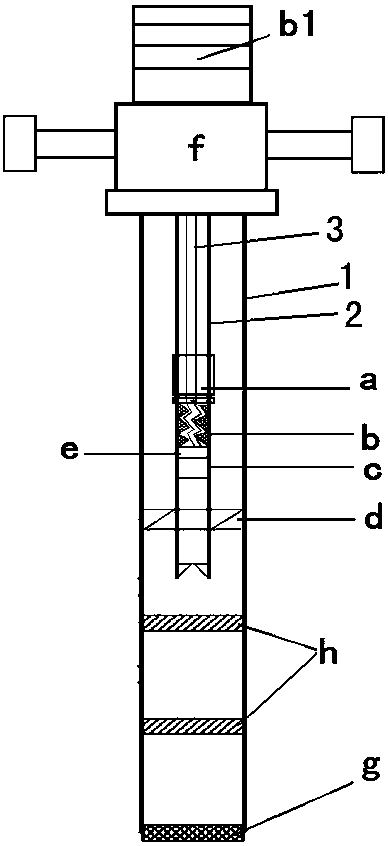

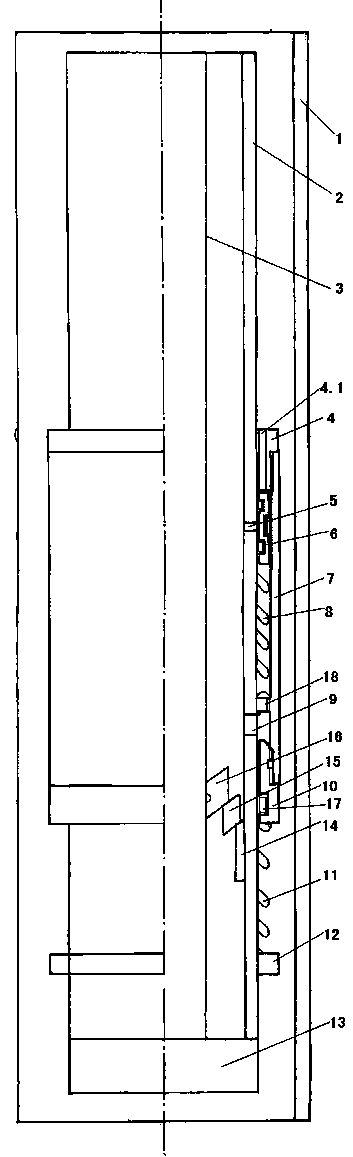

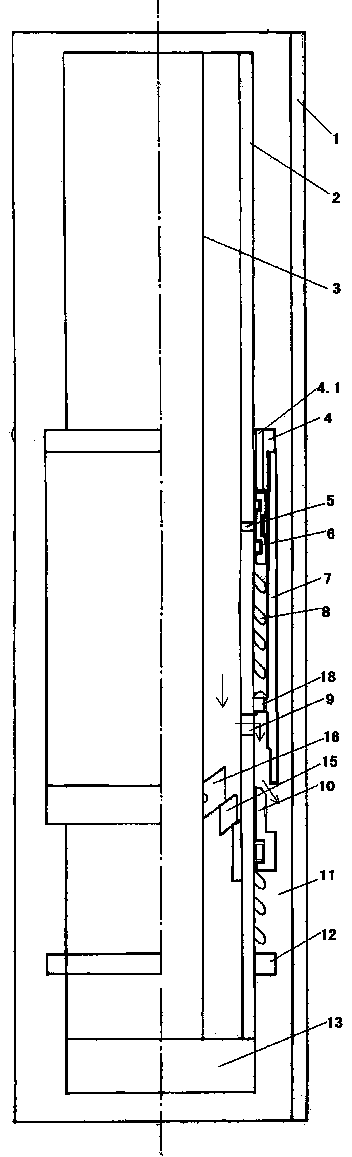

The invention relates to a using method of an all-metal screw pump heavy oil injection and production integrated device. According to the technical scheme of the using method, the all-metal screw pumpheavy oil injection and production integrated device comprises an oil production pipe column, a fixing device and a wellhead device, the wellhead device is installed at the top of a sleeve, and the fixing device is installed above plugged surfaces; the oil production pipe column is fixed and supported through the fixing device and comprises an injection and production control device, an all-metalscrew pump, a pressure testing device and a positioning device; and the injection and production control device is installed at the upper part of the all-metal screw pump, the lower part of the all-metal screw pump is installed on the fixing device through the positioning device, and the pressure testing device is installed between the fixing device and the all-metal screw pump. The using methodof the all-metal screw pump heavy oil injection and production integrated device has the beneficial effects that firstly, frequent operation construction is not needed, and the whole all-metal screw pump or part of the all-metal screw pump is not needed to be lifted upwards and put down during steam injecting, so that the operating cost is reduced, and the probability of occurrence of safety accidents caused by operation is further reduced; and steam injecting is flexible, and a large amount of high temperature and high pressure steam is not needed to be injected into a stratum once, so that potential safety hazards caused by too high pressure of the one-time injected steam are reduced.

Description

technical field The invention relates to an oil production device in the petroleum industry, in particular to a method for using an all-metal screw pump heavy oil injection and production integrated device. Background technique In the process of oil extraction, heavy oil has special characteristics of high viscosity and high freezing point, and some technical difficulties have been encountered in various aspects of development and application. Colloids, asphaltenes and long-chain paraffins cause crude oil to accumulate in reservoirs and wellbores. Fluidity becomes poor. For rod pumping wells that are widely used, when heavy oil is exploited, due to high viscosity and high wax content, the oil flow channel of the tubing is reduced, and the upward and downward resistance of the sucker rod string Increase, donkey head "fighting" phenomenon is likely to occur during the downstroke, and the load on the donkey head increases during the upstroke. In severe cases, the sucker rod wil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21B43/24E21B43/00

Inventor 李万鹏史海滨李伟刘根全张南南李建国张林朱金明李新东龙传章

Owner 刘玉友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com